Cluster-guided down-the-hole hammer drilling tool

A cluster-guided, down-the-hole hammer technology, which is used in drill pipes, drill pipes, and earth-moving drilling, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

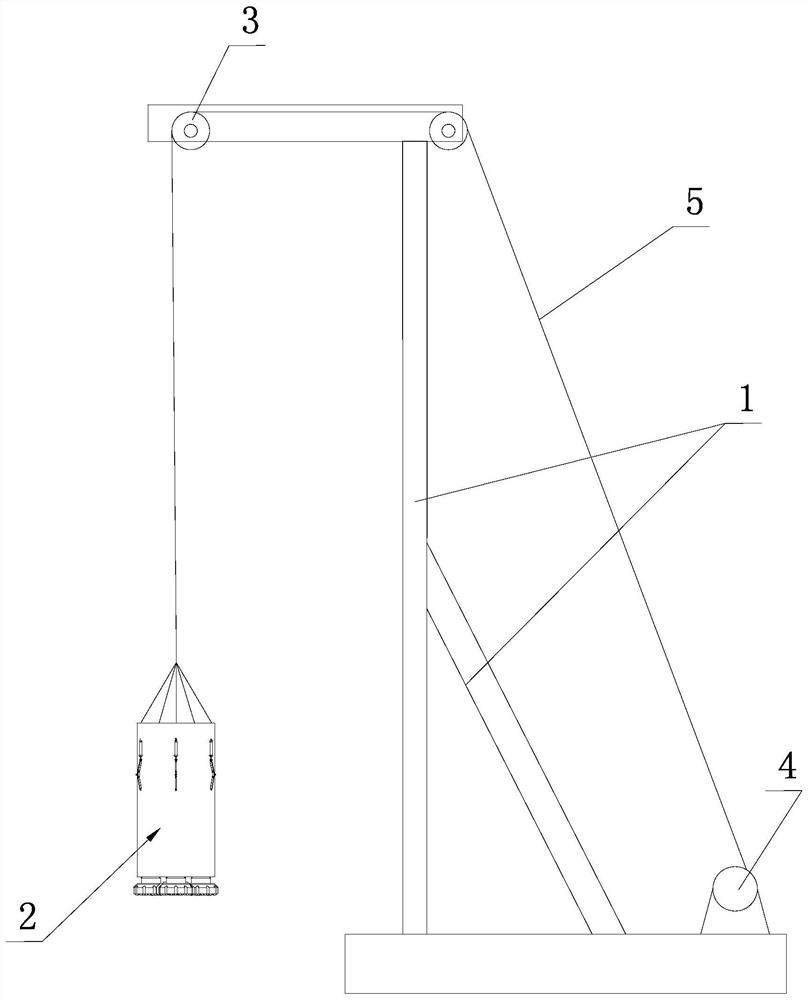

[0027] Such as Figure 1 to Figure 9 As shown, the cluster-guided down-the-hole hammer drilling tool of the present invention includes a bracket 1 and a down-the-hole hammer assembly 2, the top of the bracket 1 is provided with a fixed pulley 3, the bottom of the bracket 1 is provided with a hoist 4, and the traction rope of the hoist 4 is wound 5 times. After passing the fixed pulley 3 on the top of the support 1, it is suspended and fixed with the down-the-hole hammer assembly 2. The above content belongs to the prior art, so it will not be described in detail.

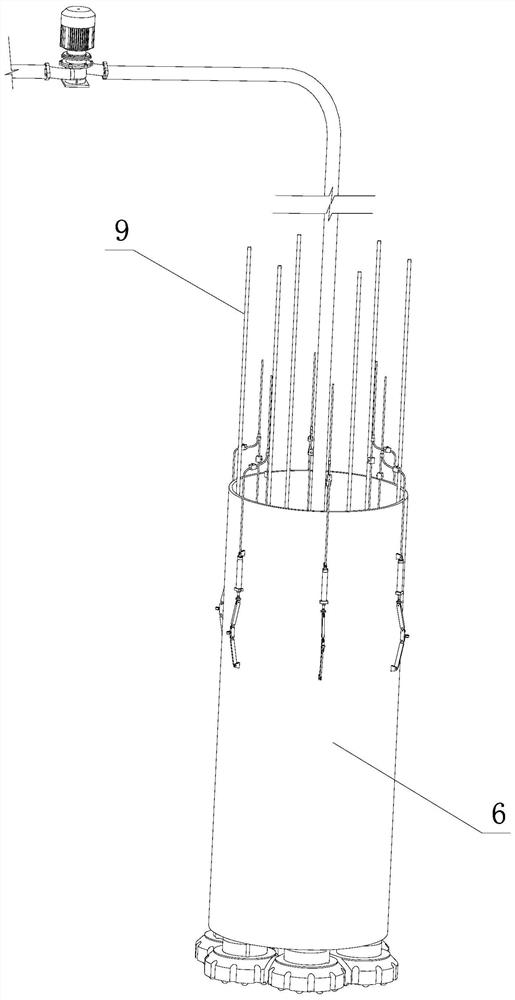

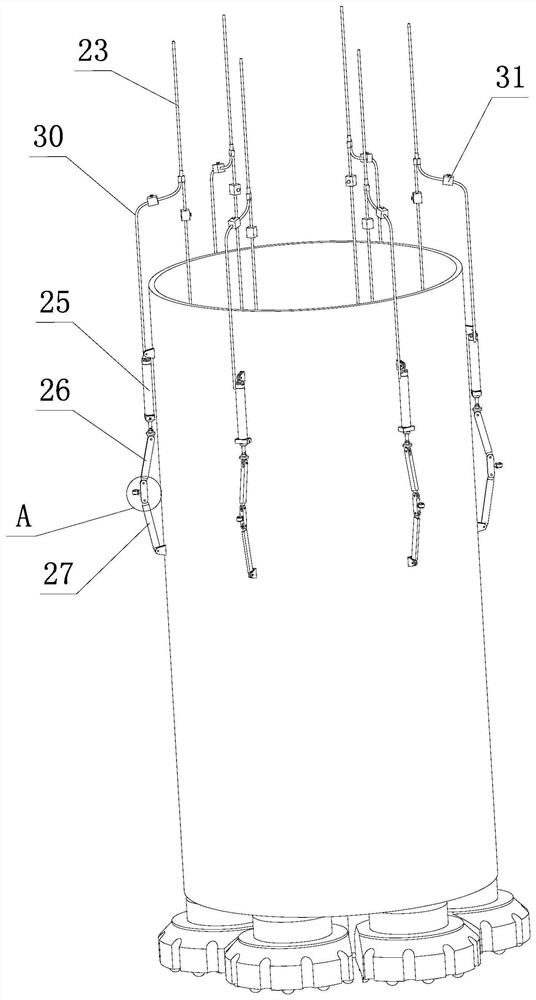

[0028] The down-the-hole hammer assembly 2 is a cluster type, which includes an installation cylinder 6. In this application, a plurality of suspension rings are arranged on the upper ring surface of the installation cylinder 6. The end of the traction rope 5 is divided into multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com