Preparation method utilizing rice for preparing nutritional rice flour

A nutritious rice flour and the technology of the production method are applied in the fields of application, function of food ingredients, food science, etc., and can solve problems such as not being able to increase gastric juice secretion and gastrointestinal digestibility, not having nourishing cells, and accelerating gastric emptying rate, etc. Achieve the effects of improving the body's immune function, enhancing the body's hematopoietic function, increasing gastric juice secretion and gastrointestinal digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

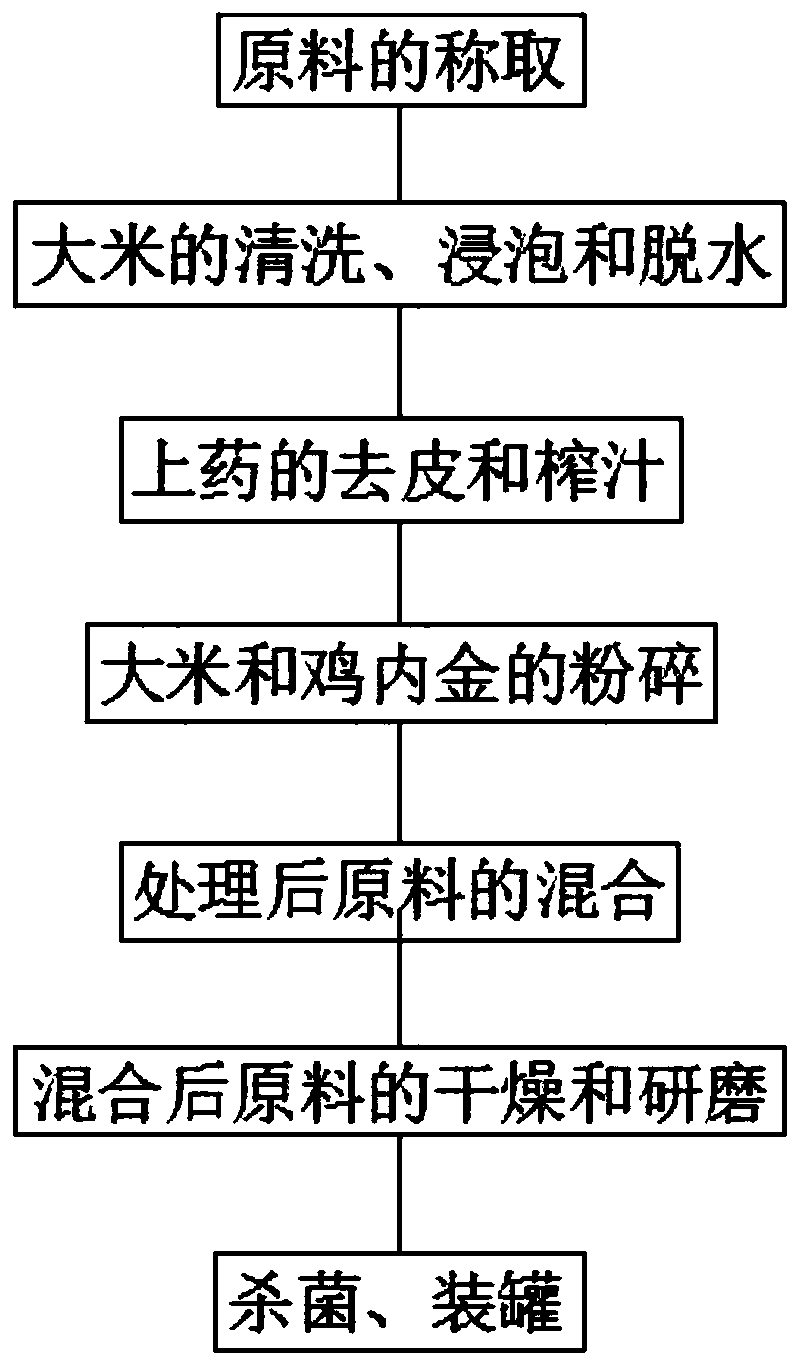

Image

Examples

Embodiment 1

[0043] The preparation method of using rice to prepare nutritious rice flour includes the following raw materials and their weight fractions: 100 g parts by mass of rice; 0.4 g of potassium dihydrogen phosphate; 12 g parts by mass of modified starch; 0.7 g parts by mass of viscosifier; The dosage is 0.8g parts by mass; the protein additive is 2.5g parts by mass.

[0044] The production method steps are as follows:

[0045] a. First, the above-mentioned raw materials are weighed according to parts by weight;

[0046] b. After step a is completed, wash the rice, yam and gallinacea with clean water, then soak the washed rice in clean water, and then put the rice into the dehydrator for dehydration;

[0047]c. After step b is completed, peel the cleaned yam, wash it with water again after peeling, and then put the yam in a press for pressing, and separate the yam juice and yam dregs after pressing;

[0048] d. After step c is completed, put the rice and gallinacea into a pulveri...

Embodiment 2

[0053] The described preparation method of utilizing rice to prepare nutritious rice noodles comprises the following raw materials and their weight fractions: 100 g parts by mass of rice; 15 g parts by mass of Chinese yam; 10 g parts by mass of gallinaceous gold; 12g parts by mass; 0.7g parts by mass of the thickener; 0.8g parts by mass of the emulsifier; 2.5g parts by mass of protein additives.

[0054] The production method steps are as follows:

[0055] a. First, the above-mentioned raw materials are weighed according to parts by weight;

[0056] b. After step a is completed, wash the rice, yam and gallinacea with clean water, then soak the washed rice in clean water, and then put the rice into the dehydrator for dehydration;

[0057] c. After step b is completed, peel the cleaned yam, wash it with water again after peeling, and then put the yam in a press for pressing, and separate the yam juice and yam dregs after pressing;

[0058] d. After step c is completed, put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com