A baby powder applicator

A talcum powder and applicator technology, applied in cosmetic powder containers, household containers, dressing containers, etc., can solve the problems of floating into the eyes of babies, waste, and baby injuries, and achieves avoiding injury, reducing waste, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

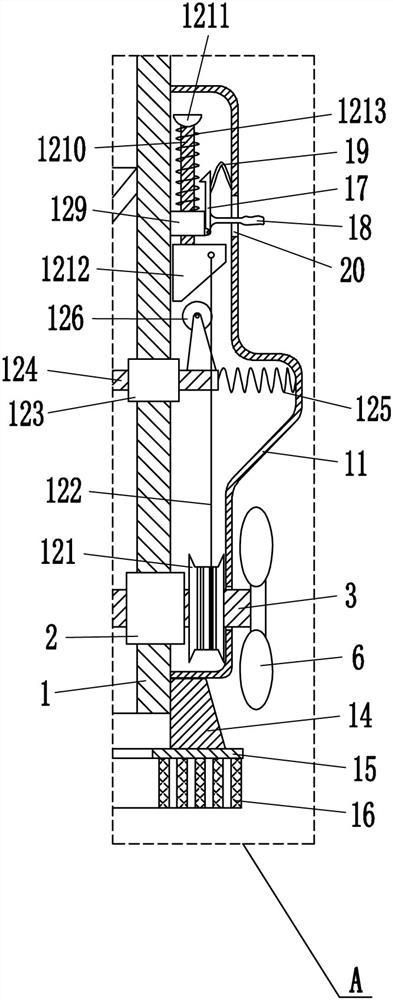

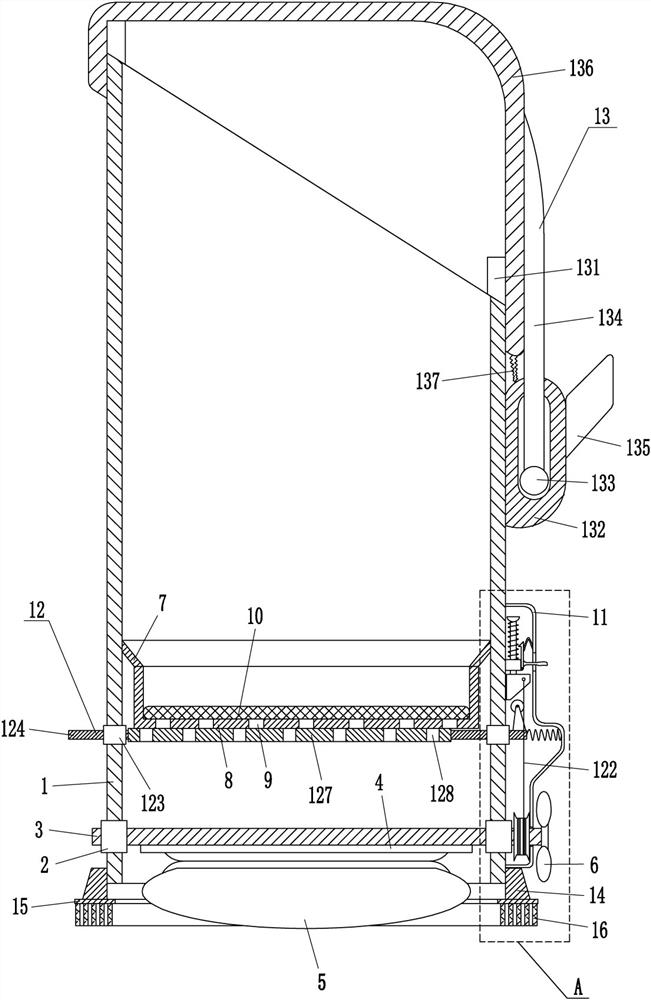

[0016] A baby powder applicator such as Figure 1-2 As shown, it includes a casing 1, a shaft sleeve 2, a rotating shaft 3, a mounting plate 4, a powder puff 5, a knob 6, a connecting ring 7, a frame body 8, a mesh plate 10, a protective casing 11, and a feeding mechanism 12. The lower part of the casing 1 is left and right The shaft sleeves 2 are embedded on both sides, and the shaft 3 is connected between the two shaft sleeves 2. The bottom of the shaft 3 is fixed with the installation plate 4. The shaft 3 is connected to the installation plate 4 through bolt connection, and the bottom of the installation plate 4 is connected There is a powder puff 5 for applying talcum powder, the knob 6 is fixed to the right end of the rotating shaft 3, the knob 6 is connected to the rotating shaft 3 by welding, and the inner lower part of the shell 1 is fixed with a frame 8 for holding talcum powder through a connecting ring 7, The connecting ring 7 is connected to the frame body 8 by mea...

Embodiment 2

[0018] A baby powder applicator such as Figure 1-2 As shown, it includes a casing 1, a shaft sleeve 2, a rotating shaft 3, a mounting plate 4, a powder puff 5, a knob 6, a connecting ring 7, a frame body 8, a mesh plate 10, a protective casing 11, and a feeding mechanism 12. The lower part of the casing 1 is left and right The shaft sleeves 2 are embedded on both sides, the shaft 3 is connected between the two shaft sleeves 2, the bottom of the shaft 3 is fixedly connected with the installation plate 4, the bottom of the installation plate 4 is connected with the powder puff 5 for applying talcum powder, and the knob 6 is fixedly connected At the right end of the rotating shaft 3, the inner lower part of the housing 1 is fixedly connected with a frame 8 for holding talcum powder through a connecting ring 7, and the bottom of the frame 8 is evenly spaced with discharge ports 9 for falling the talcum powder, and the bottom of the frame 8 is A mesh plate 10 for filtering impurit...

Embodiment 3

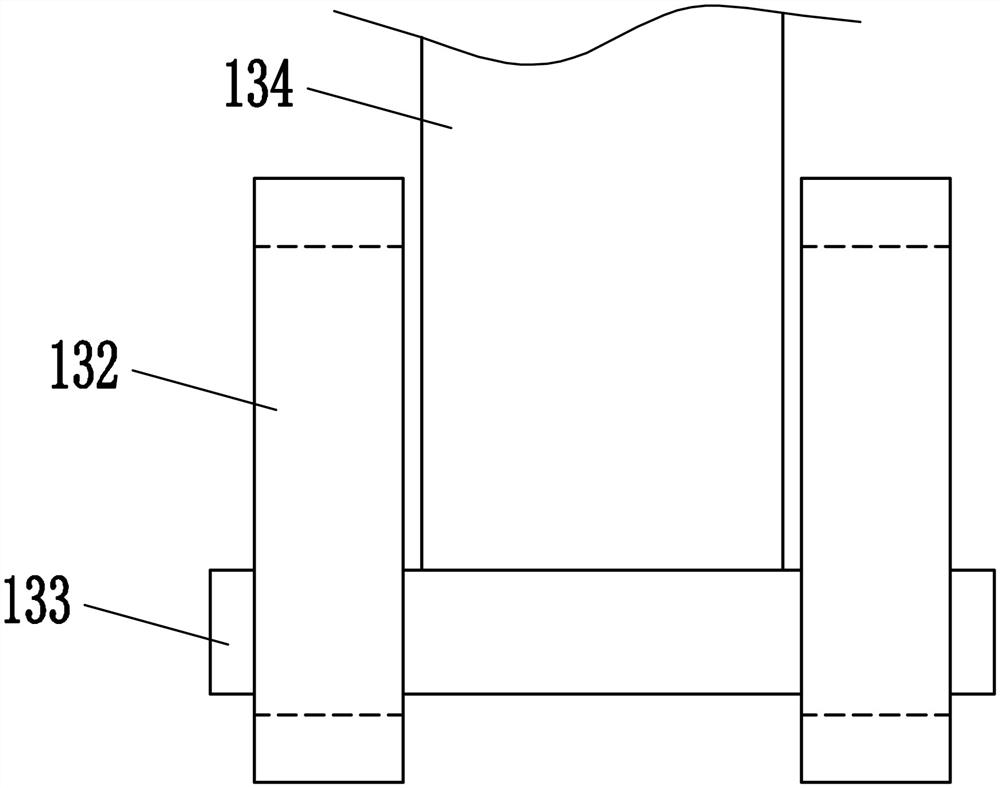

[0021] A baby powder applicator such as Figure 1-3 As shown, it includes a casing 1, a shaft sleeve 2, a rotating shaft 3, a mounting plate 4, a powder puff 5, a knob 6, a connecting ring 7, a frame body 8, a mesh plate 10, a protective casing 11, and a feeding mechanism 12. The lower part of the casing 1 is left and right The shaft sleeves 2 are embedded on both sides, the shaft 3 is connected between the two shaft sleeves 2, the bottom of the shaft 3 is fixedly connected with the installation plate 4, the bottom of the installation plate 4 is connected with the powder puff 5 for applying talcum powder, and the knob 6 is fixedly connected At the right end of the rotating shaft 3, the inner lower part of the housing 1 is fixedly connected with a frame 8 for holding talcum powder through a connecting ring 7, and the bottom of the frame 8 is evenly spaced with discharge ports 9 for falling the talcum powder, and the bottom of the frame 8 is A mesh plate 10 for filtering impurit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com