A high-strength metamorphic alloy hammer head for a sand making machine

A modified alloy and high-strength technology, applied in the field of high-strength modified alloy hammers for sand making machines, can solve the problems of unsatisfactory mechanical strength of hammers, short service life, and falling off of hammers, so as to improve the connection firmness, The effect of improving the service life and improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

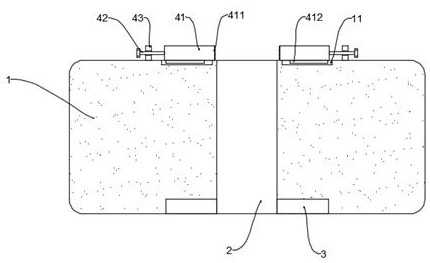

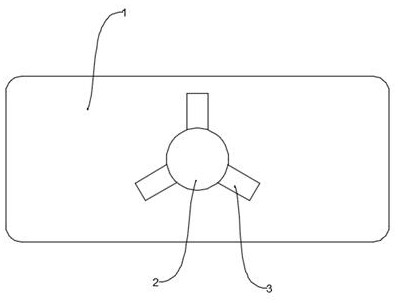

[0026] see Figure 1~2 , in an embodiment of the present invention, a high-strength metamorphic alloy hammer head for a sand making machine includes a hammer body 1 with a cuboid structure, and a mounting hole 2 is opened at the center of the hammer body 1; the bottom of the hammer body 1 corresponds to the mounting hole 2 is provided with a plurality of key grooves 3, and the plurality of key grooves 3 are equidistantly arranged on the periphery of the mounting hole 2 along the circumference. The firmness of the connection with the transmission rod of the sand making machine;

[0027] The top of the hammer body 1 is provided with a plurality of positioning components corresponding to the position of the mounting hole 2, and a plurality of positioning components are equidistantly arranged on the periphery of the mounting hole 2 along the circumferential direction. Specifically, the positioning components include snapping Block 41, the engaging block 41 is arc-shaped, the bott...

Embodiment 2

[0031] This embodiment provides a masterbatch for making hammerheads, the masterbatch is composed of the following components according to mass percentage: 0.003% tin, 1.19% manganese, 3.40% sodium chloride, 4.65% chromium, and the balance is iron .

[0032] The preparation method of described master batch comprises the following steps:

[0033] 1) Add 2 times the mass of water to sodium chloride to prepare a sodium chloride solution, then put the iron, tin and sodium chloride solution into the reaction kettle and seal it, and heat it at 450°C for 8 minutes; get the first mixture;

[0034] 2) Put the first mixture into the melting furnace and melt it at 860°C for 20 minutes to obtain the second mixture;

[0035] 3) Add chromium to the second mixture, raise the temperature to 1050°C and continue smelting for 5 minutes while removing slag to obtain the third mixture;

[0036] 4) Add manganese into the third mixture, continue smelting at a temperature of 1050°C for 40 minutes,...

Embodiment 3

[0040] This embodiment provides a masterbatch for making hammerheads, the masterbatch is composed of the following components according to mass percentage: 0.0035% tin, 1.20% manganese, 3.42% sodium chloride, 4.68% chromium, and the balance is iron .

[0041] The preparation method of described master batch comprises the following steps:

[0042] 1) Add 3 times the mass of water to sodium chloride to prepare a sodium chloride solution, then put the iron, tin and sodium chloride solution into the reaction kettle and seal it, and heat it at 550°C for 10 minutes; get the first mixture;

[0043] 2) Put the first mixture into the melting furnace and melt it at 900°C for 25 minutes to obtain the second mixture;

[0044] 3) Add chromium to the second mixture, raise the temperature to 1100°C and continue smelting for 8 minutes, and remove slag at the same time to obtain the third mixture;

[0045] 4) Add manganese into the third mixture, continue smelting at 1100°C for 50 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com