Part cleaning device based on fixed-point scrubbing technology for industrial production

The technology of a cleaning device and a spray cleaning device is applied in the direction of cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils, etc., which can solve problems such as parts are prone to collision, parts precision is reduced, and cleaning effect is reduced. Protect safety, reduce maintenance cycle, and improve cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

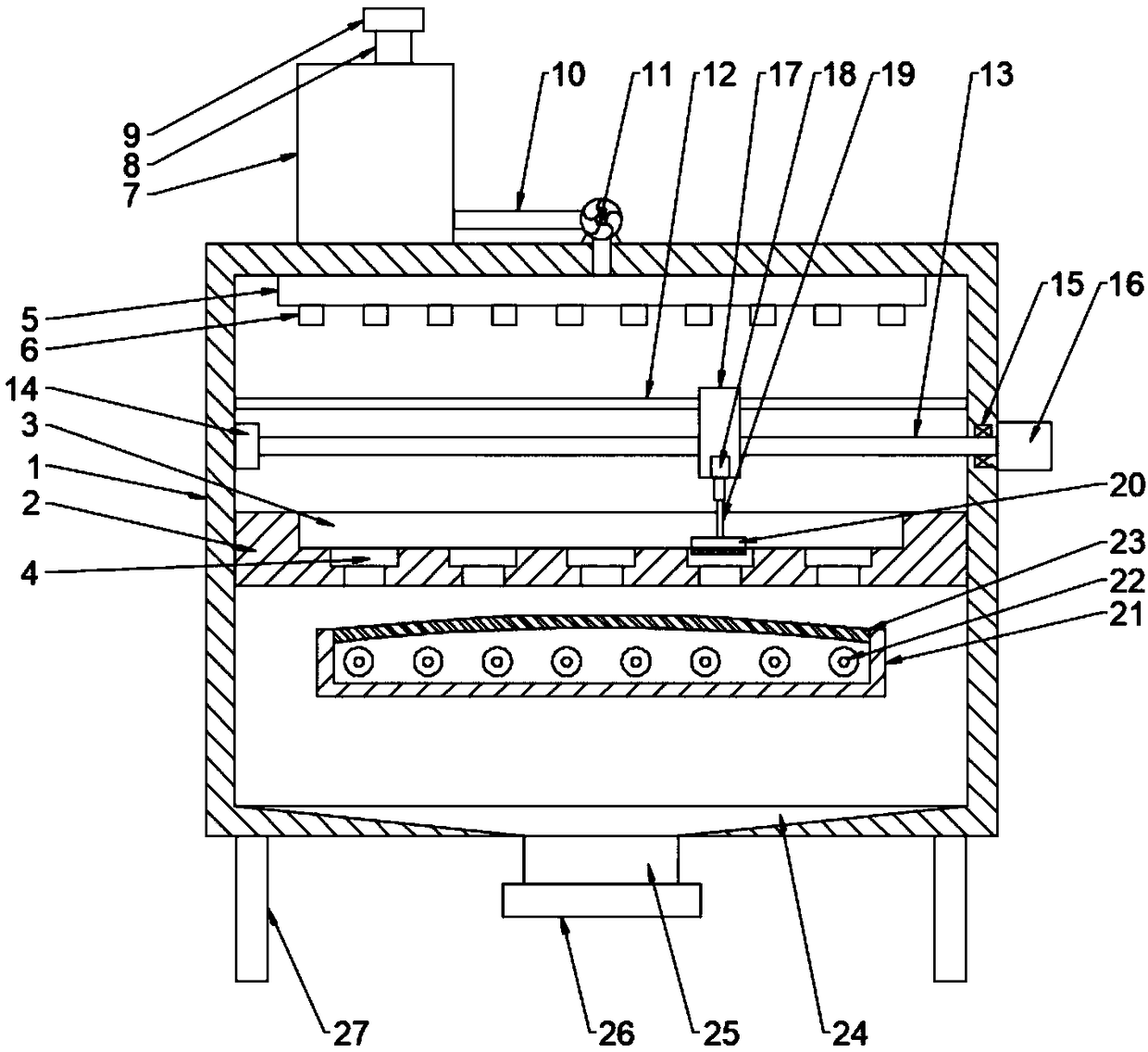

[0025] see Figure 1~3 , a parts cleaning device for industrial production based on fixed-point scrubbing technology, comprising a box body 1, a support plate 2 is provided in the middle of the inner cavity of the box body 1, and the support plate 2 is made of a transparent material, and the support plate 2 The middle part of the top surface is provided with a storage chamber 3, and the inner cavity bottom wall of the storage chamber 3 is evenly provided with a number of storage holes 4, the storage holes 4 are stepped holes, and the storage holes 4 are used to place parts; the box body 1 The top wall of the inner cavity is provided with a spray washing device 5 matched with the storage chamber 3, and several nozzles 6 are uniformly arranged on the spray washing device 5.

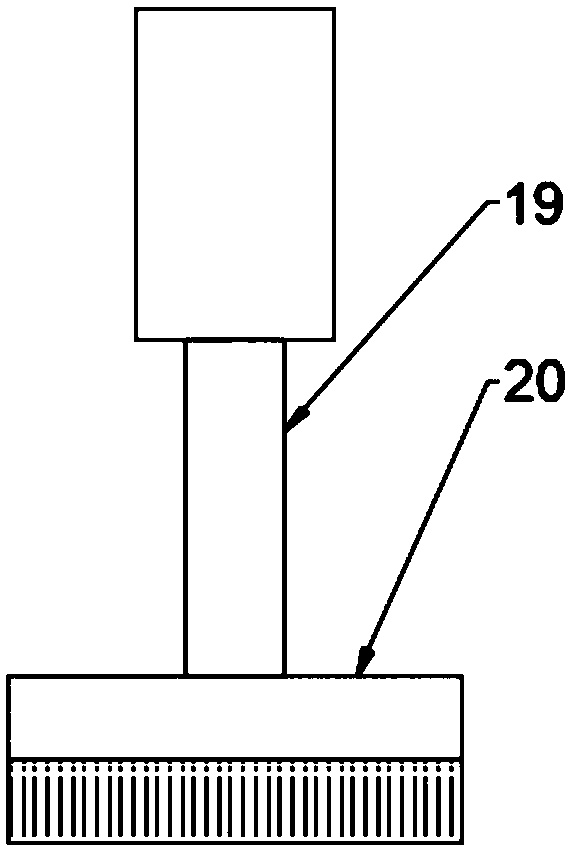

[0026] The upper part of the inner cavity of the box body 1 is provided with a slide bar 12 and a lead screw 13, the relationship between the lead screw 13 and the slide bar 12 is parallel to each other, an...

Embodiment 2

[0028] This embodiment is a further elaboration on the basis of Embodiment 1. A cleaning liquid tank 7 is provided on the top side of the box body 1, and the bottom end of one side of the cleaning liquid tank 7 is connected to a water pipe 10 through. The other end of the water pipe 10 is connected through the spray washing device 5, the water pipe 10 is provided with a booster pump 11, the top of the cleaning liquid tank 7 is connected with the liquid feeding pipe 8, and the top of the liquid feeding pipe 8 is sleeved with a The sealing plug 9 provides cleaning liquid to the spraying device 5 through the cleaning liquid tank 7 to ensure continuous cleaning work.

Embodiment 3

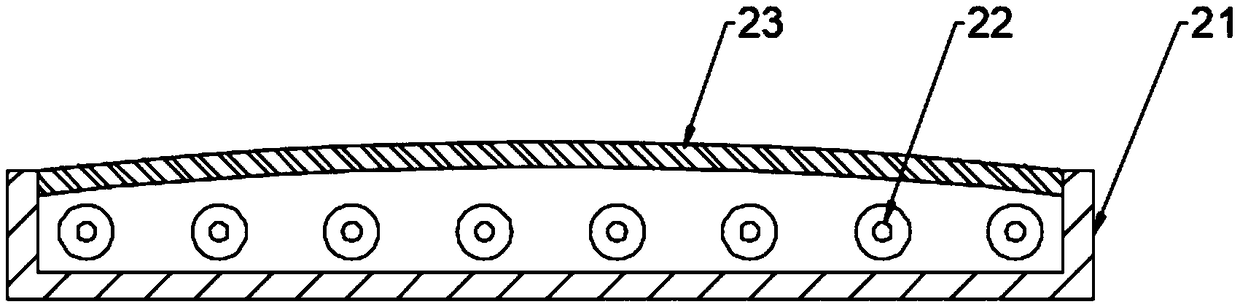

[0030] This embodiment is a further elaboration on the basis of Embodiment 1. The bottom of the inner cavity of the box body 1 is provided with a drying box 21 that matches the storage hole 4, and the drying box 21 is an open-top structure. , the inner cavity of the drying box 21 is evenly provided with some drying lamps 22, and the top opening of the drying box 21 is provided with a protective cover 23, and the protective cover 23 is made of transparent glass, and the protective cover 23 is convex. The spherical structure is used to dry the cleaned parts through the drying lamp 22, so that the parts can be dried quickly and the maintenance period can be reduced.

[0031] The bottom wall of the inner cavity of the box body 1 is connected through the drain hole 24, the drain hole 24 is a tapered hole, the bottom of the drain hole 24 is connected to the drain pipe 25, and the bottom end of the drain pipe 25 is provided with a seal. Cover 26, the sewage and impurities generated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com