Forged piece edge-cutting and correcting system

A correction system and edge trimming technology, applied in the field of forging, can solve the problems of lack of flexibility, stability, and inability to adjust, and achieve the effects of good use effect, good operation effect, and improved applicability and practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

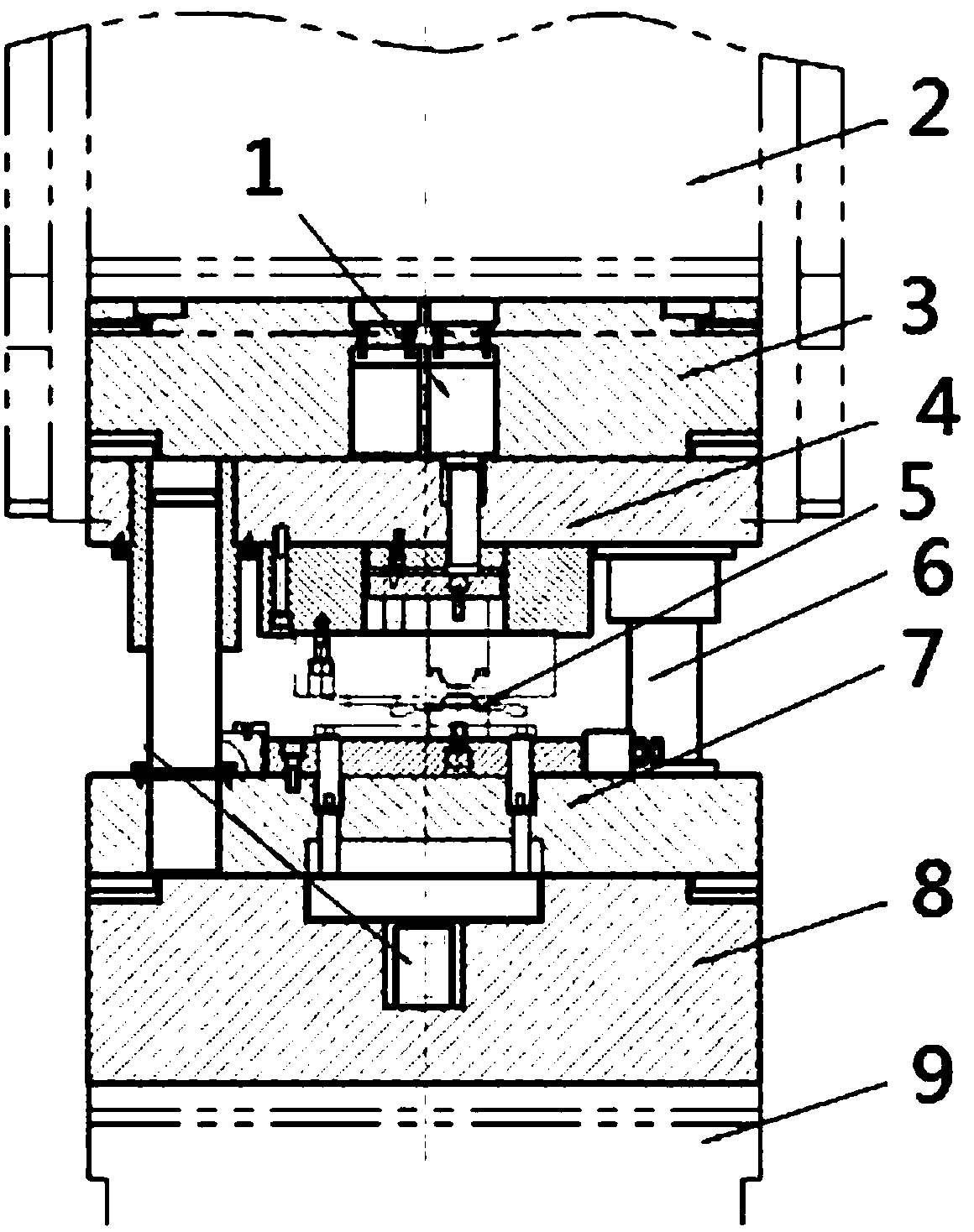

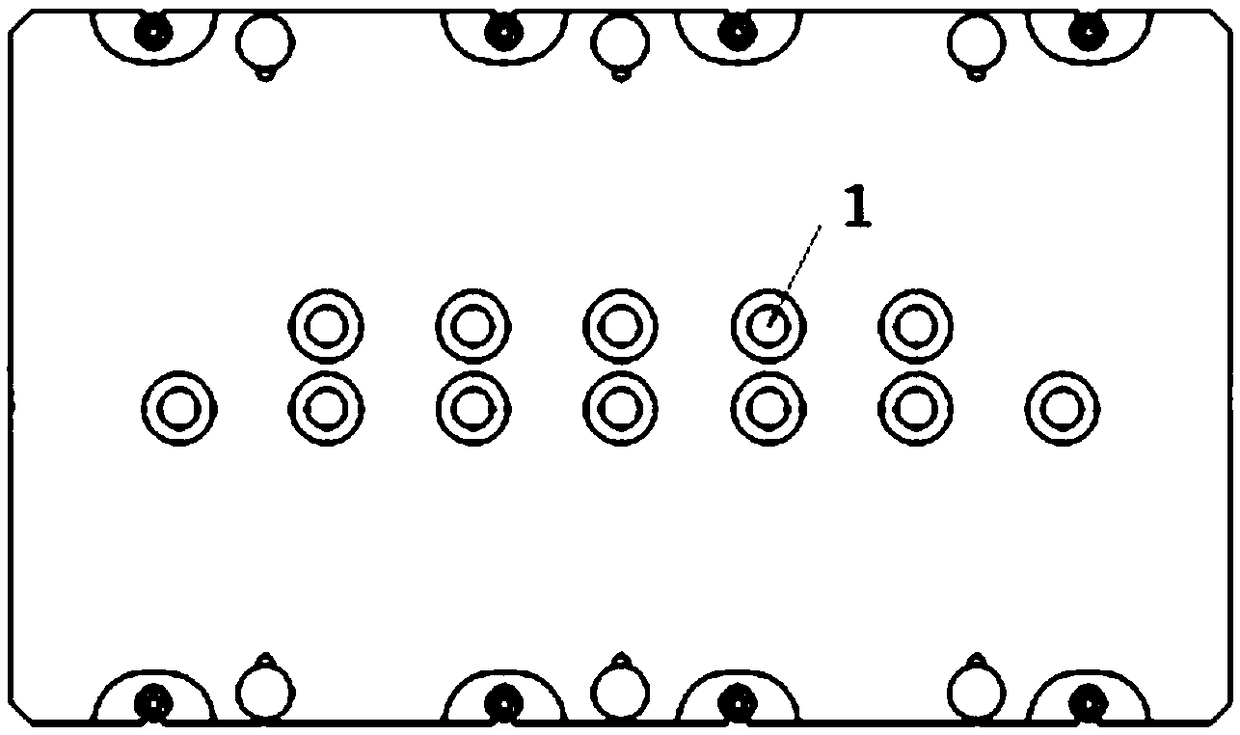

[0039] Such as figure 1-2 shows a specific implementation of the forging edge trimming correction system involved in the present invention. The forging edge trimming correction system includes: a worktable 9, a lower backing plate 8, an edge trimming correction assembly 5, a first drive assembly, a second drive assembly, at least one set of hydraulic devices, a guide assembly, a mounting assembly, and a temperature sensor.

[0040] In this embodiment, the lower backing plate 8 is disposed on the workbench 9 .

[0041] In this embodiment, the edge trimming correction assembly 5 is used for trimming the forging and performing correction while trimming, such as figure 1 As shown, the trimming correction assembly 5 includes a first trimming correction assembly at the top and a second trimming correction assembly at the bottom, and the first trimming correction assembly can be positioned relative to the second trimming correction assembly Move up and down in the vertical directio...

Embodiment 2

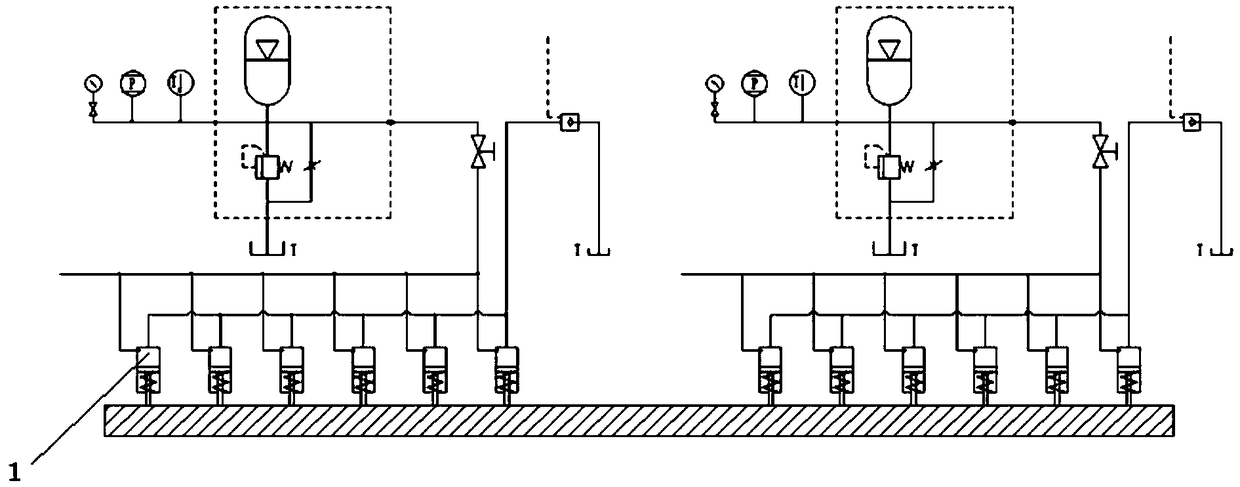

[0052] Different from Example 1, as image 3 As shown, the hydraulic device is arranged in two groups, and the hydraulic cushion plunger cylinder in each group of the hydraulic device is connected to an accumulator, and the back pressure provided by the hydraulic device of the two groups is different, so different groups of The hydraulic cushion plunger cylinder can have different pressures, so that the back pressure exerted on different parts of the forging with complex shapes is also different, realizing a more flexible trimming correction function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com