Full automatic assembling technology of air valve of rocker arm of engine and production line

A technology for engine valves and assembly production lines, which is applied to assembly machines, manufacturing tools, metal processing equipment, etc., and can solve problems such as the inability to increase operators, the inability to meet production needs, and the reduction of the number of equipment operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

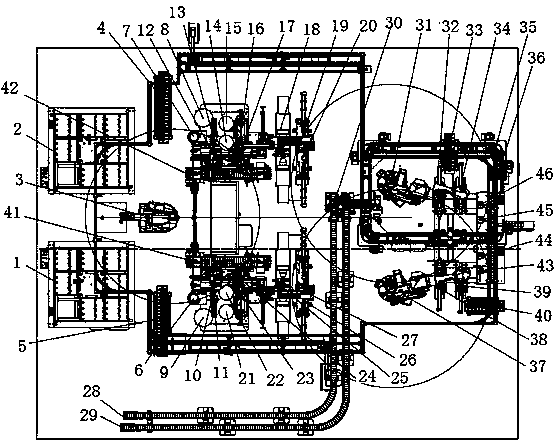

[0098] The fully automatic assembly process of the engine rocker arm of the present invention is as follows.

[0099] 1. Rocker loading:

[0100] ①Feed through the slide table, place the positioning tray on the slide table, feed the intake rocker arm to the positioning tray of the intake rocker slide table, and load the exhaust rocker arm to the positioning tray of the exhaust rocker slide table; the positioning tray There is a detection mechanism for the presence or absence of workpieces.

[0101] The intake rocker slide table and the exhaust rocker slide table are arranged in parallel, and each slide table is placed with a positioning tray to realize continuous feeding without stopping the machine.

[0102] ②The rocker arm is sent to the working area of the robot through the slide table, the robot automatically grabs the rocker arm according to the set program, and automatically memorizes the position and direction of the rocker arm in the positioning tray, and after grab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com