Electromagnetic clamp

An electromagnetic fixture and electromagnetic technology, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of size specification restrictions, difficulty in meeting flatness and dimensional position accuracy, and inability to adjust PCB deflection angle, etc., to achieve the effect of avoiding bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

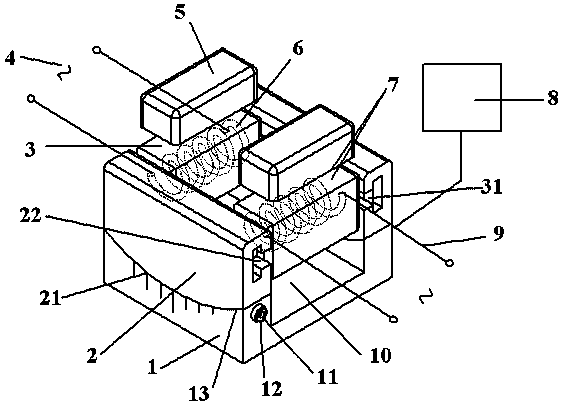

[0034] An electromagnetic clamp is characterized in that it includes a base 1, a guide rail support 2, an electromagnetic base 3, a coil 6, an electromagnetic pressing block 5, an AC power supply 4, a monitoring module 8, and an electric wire 9, and arcs are arranged at both ends of the base. Shaped guide rail 13, the arc-shaped guide rail is respectively connected with the guide rail supports 2 on the left and right sides, the guide rail support 2 is connected with the electromagnetic base 3 through the sliding guide rail 22 / 31, and the electromagnetic base 3 is equipped with an electromagnetic The pressing block 5, two coils 6 are arranged in the middle of the electromagnetic base 3, the coils 6 are connected to the AC power supply 4 through the wire 9, and the wire 9 is also connected to the monitoring module 8. In particular, the base 2, guide rail support 2, electromagnetic base 3, coil 6, electromagnetic pressing block 5, AC power supply 4, monitoring module 8, and electr...

Embodiment 2

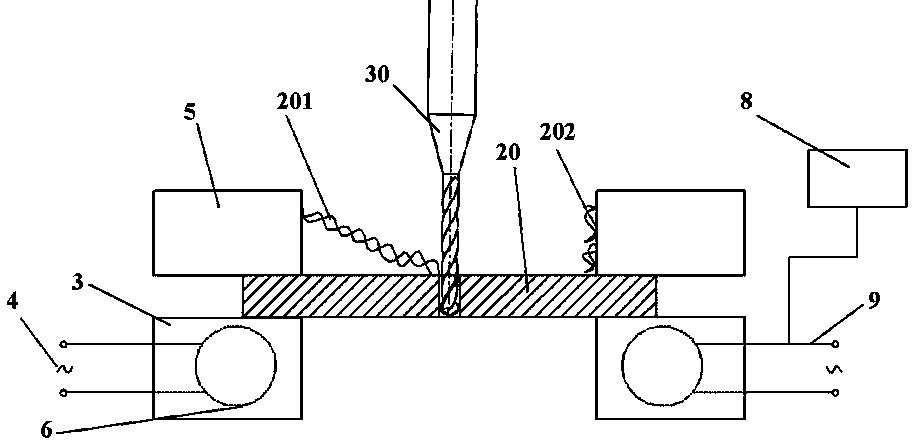

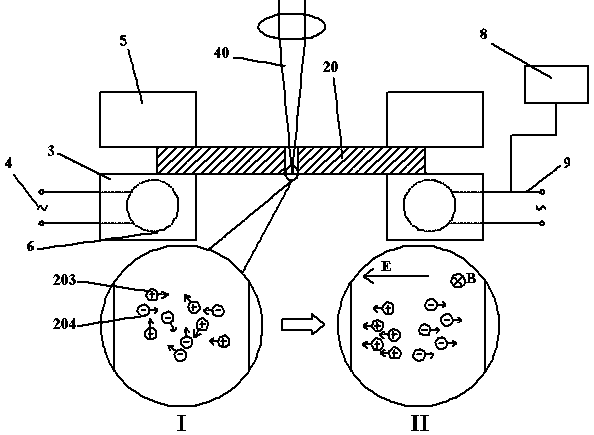

[0049] This embodiment provides a method of clamping and processing rigid plates using the electromagnetic fixture of Embodiment 1: adjust the relative position of the electromagnetic base 3 according to the size of the plate 20, and after adjusting to the corresponding position, place the plate 20 on the electromagnetic base On the seat 3, turn on the AC power supply 4, and the coil 6 produces a magnetic field under the action of the alternating current. Under the action of the magnetic field, the electromagnetic pressing block 5 and the electromagnetic base 3 are pressed together to achieve the function of fixing the plate 20. Through the detection module 8 Detect and display the size of the pressing force, adjust the output parameters of the AC power supply 4 according to the type of the plate 20, and adjust the mutual deflection position of the base 1 and the guide rail support 2 at the same time, determine the deflection angle through the scale on the base 1, and use the lo...

Embodiment 3

[0051] This embodiment provides a method of clamping and processing flexible plates and rigid-flexible plates using the electromagnetic fixture of Embodiment 1: place the plate 20 on the electromagnetic base 3, turn on the AC power supply 4, and the coil 6 will act under the action of the alternating current. A magnetic field is generated under the action of the magnetic field. Under the action of the magnetic field, the electromagnetic pressing block 5 and the electromagnetic base 3 are pressed together to achieve the effect of fixing the plate 20, and adjust the relative position of the electromagnetic base 3 so that the degree of relaxation of the soft board part of the plate 20 is constant. It presents a flat state, detects and displays the size of the pressing force through the detection module 8, adjusts the output parameters of the AC power supply 4 according to the type of the plate 20, and adjusts the mutual deflection position of the base 1 and the guide rail support 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com