Steel plate double-surface polishing device

A double-sided, steel plate technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems of turning over the steel plate, reducing the efficiency of steel plate grinding, and time-consuming grinding, so as to improve the operation efficiency, The effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

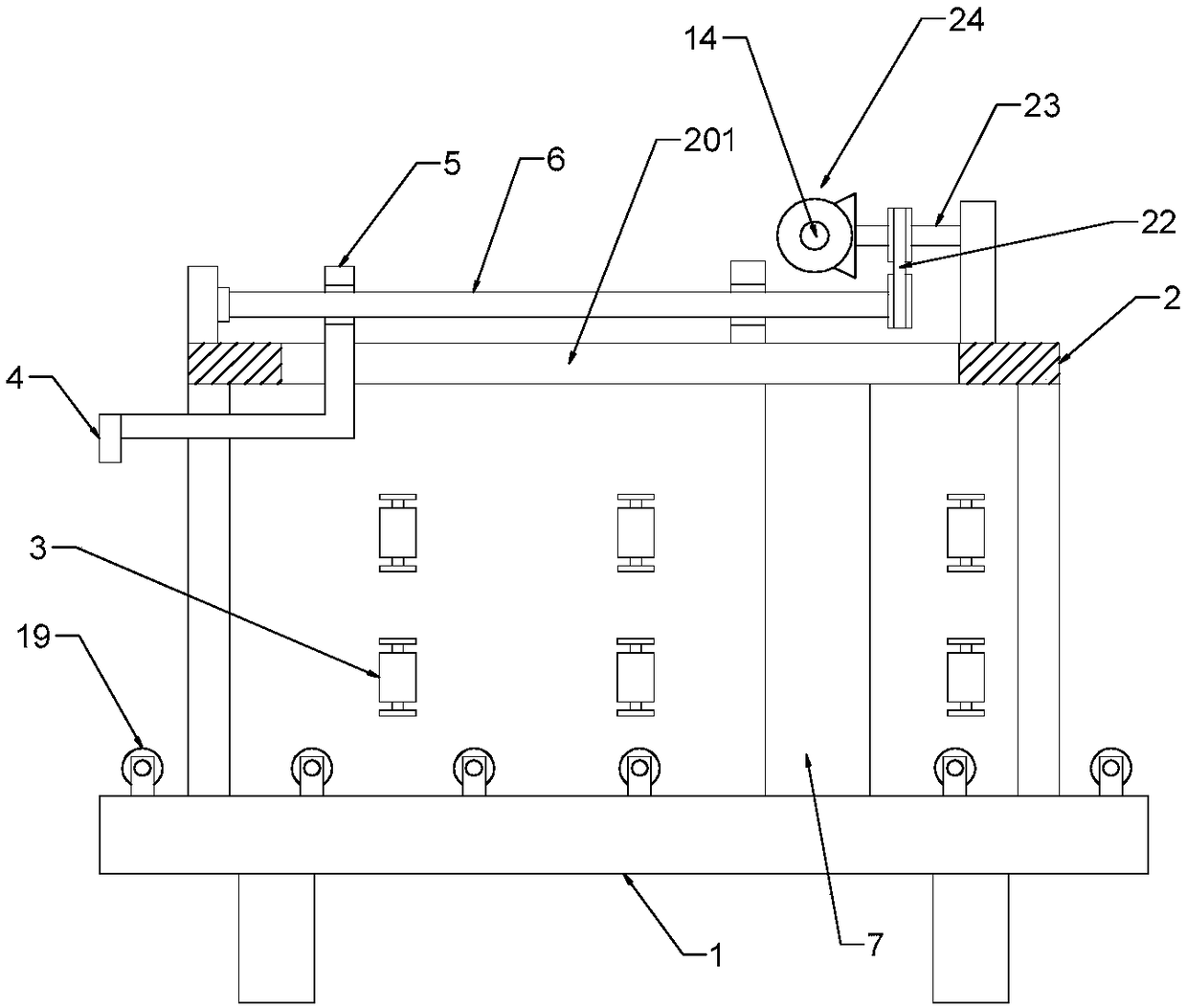

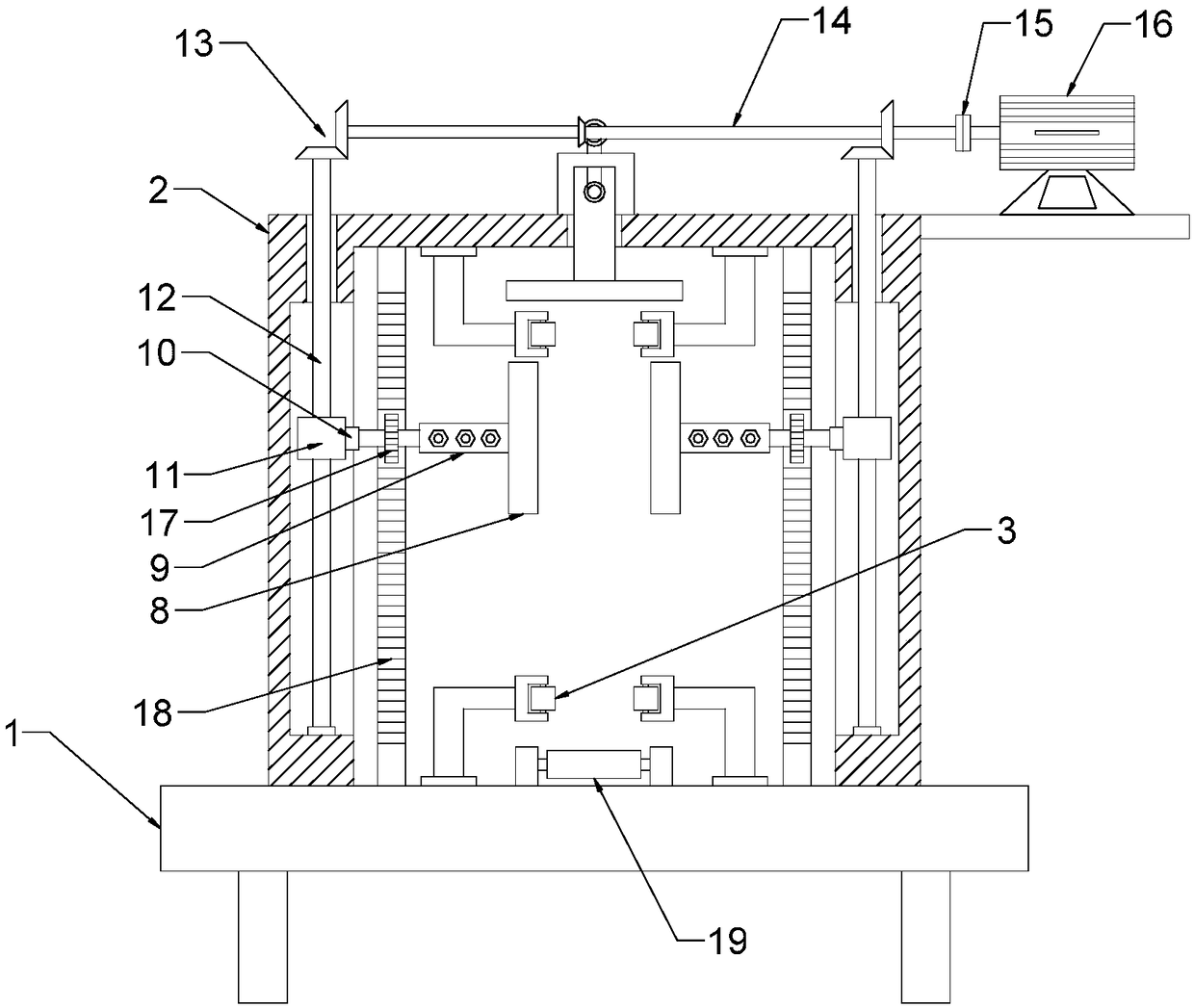

[0021] see Figure 1~2 , in an embodiment of the present invention, a steel plate double-sided grinding device includes a base 1, a box body 2 and a grinding mechanism 7; the base 1 is fixedly connected with a box body 2, and the box body 2 is a hollow box with two ends close to the mouth body, the base 1 is provided with support rollers 19 equidistantly distributed, the support rollers 19 provide support for the steel plate, and the guide rollers 3 are arranged symmetrically above the support roller 19, and the guide rollers 3 squeeze and guide the steel plates, and the guide rollers 3 pass through the The mode of bolt fixing is fixedly connected with the inner wall of the box body 2; the grinding mechanism 7 includes a symmetrically arranged grinding disc 8, the inner side of the grinding disc 8 is fixedly connected with a telescopic rod 9, and the telescopic rod 9 is connected with a moving block 11 through a bearing seat 10 in rotation, The moving block 11 is nested in the...

Embodiment 2

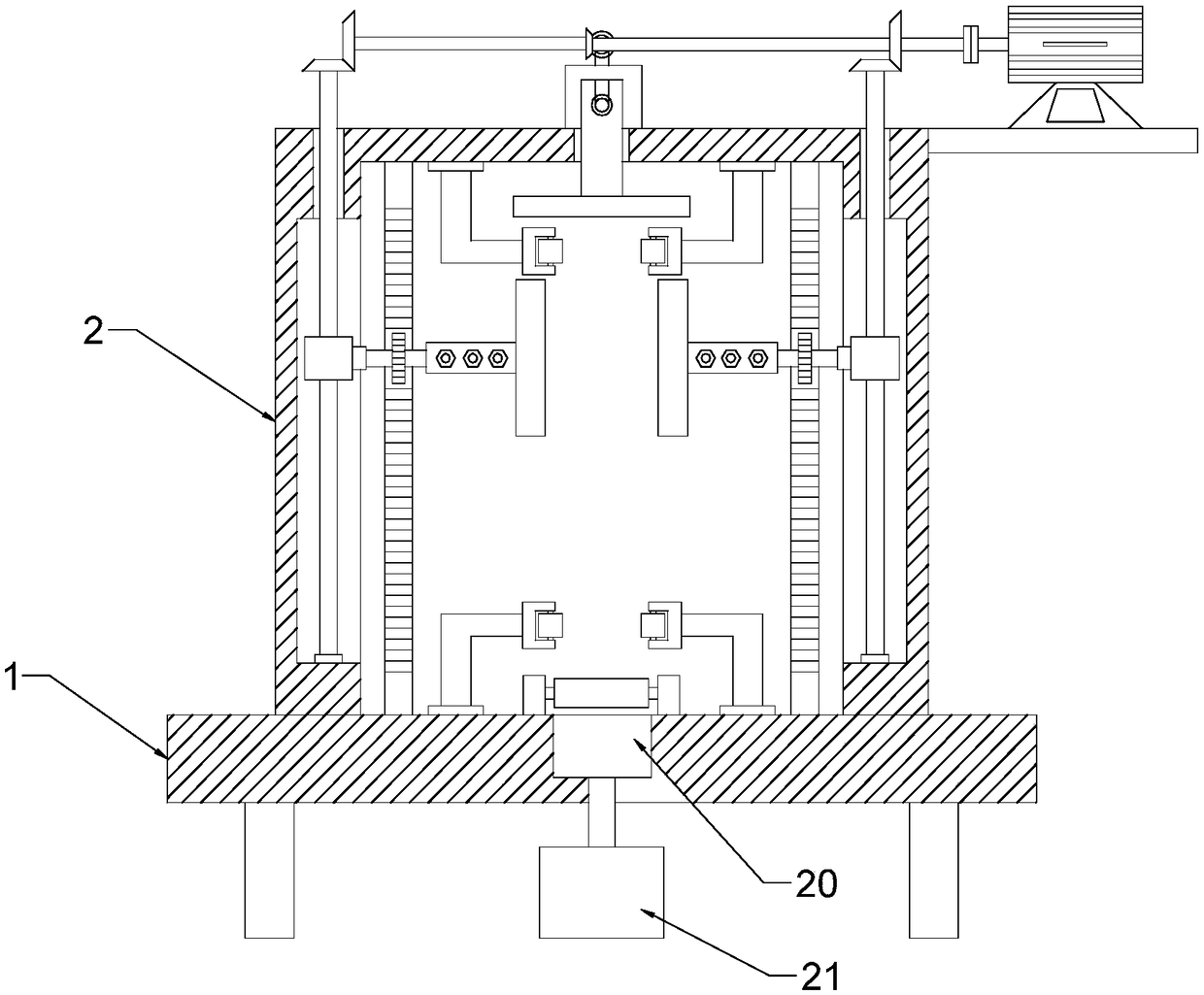

[0024] see image 3 The difference between this embodiment and Embodiment 1 is that: the bottom of the base 1 is provided with a dust collection cover 20, and the dust collection cover 20 is connected with a vacuum cleaner 21, and the vacuum cleaner 21 collects grinding debris.

[0025] It should be noted that: the grinding disk and the vacuum cleaner in this application are prior art; by being provided with a push plate driven by a horizontal screw rod, a support roller and a guide roller, the steel plate is fixed and the steel plate is kept fed to improve the grinding efficiency; Equipped with a symmetrical grinding disc that moves up and down and rotates driven by a vertical screw rod, it can grind the steel plate on both sides to improve the working efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com