Lifting battery frame for lifting power changing space of electric vehicle and lifting method

A technology for electric vehicles and battery frames, applied to electric vehicles, lifting frames, lifting devices, etc., can solve the problems of narrow space for battery replacement, low efficiency of battery replacement, long charging time, etc., to reduce the error of lifting distance and improve battery replacement Space, the effect of improving the efficiency of battery replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

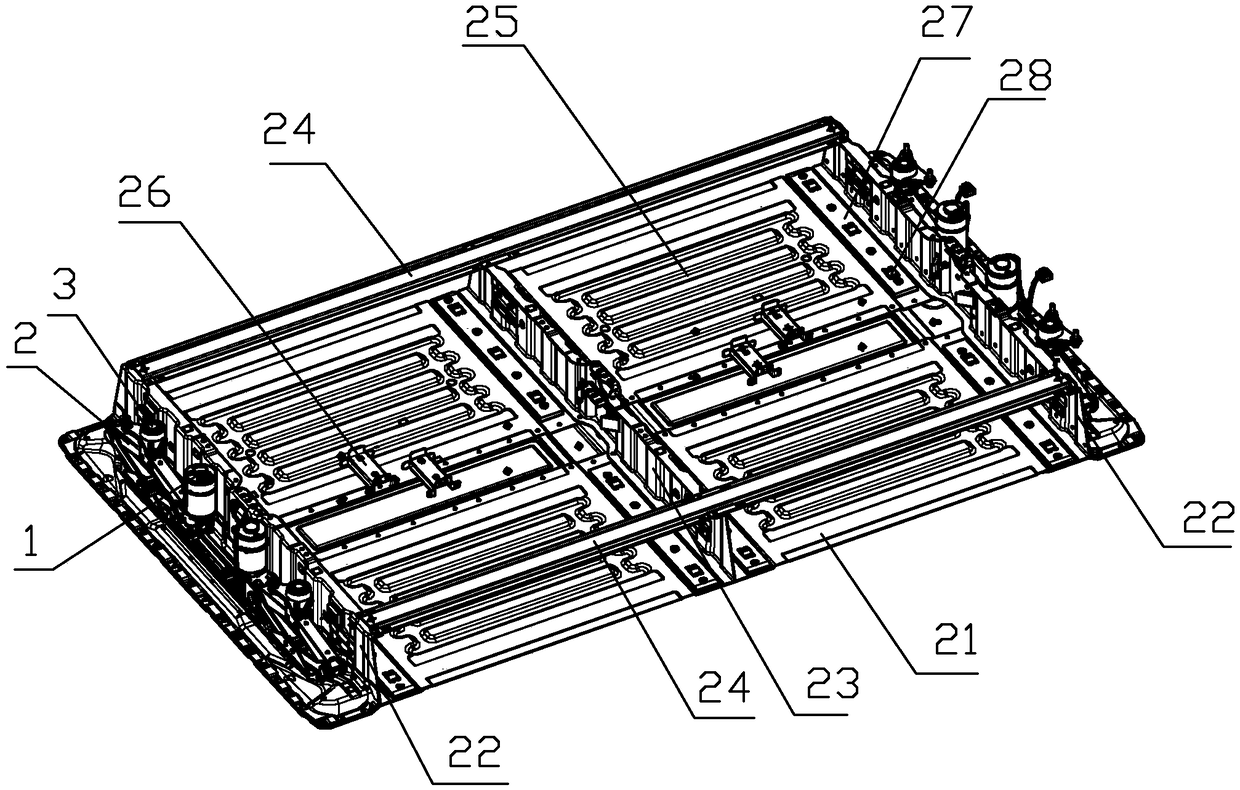

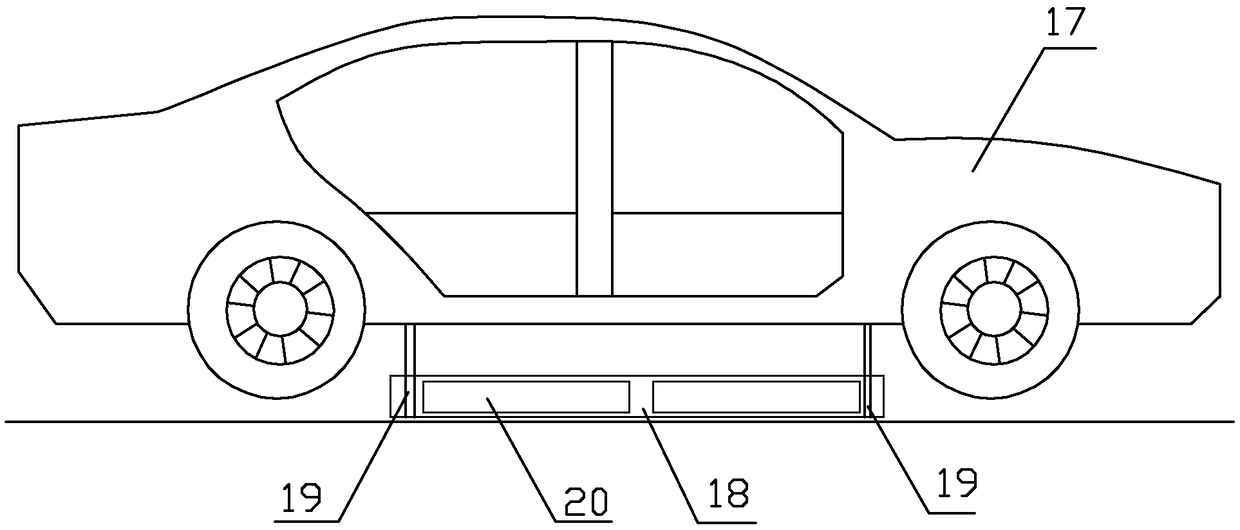

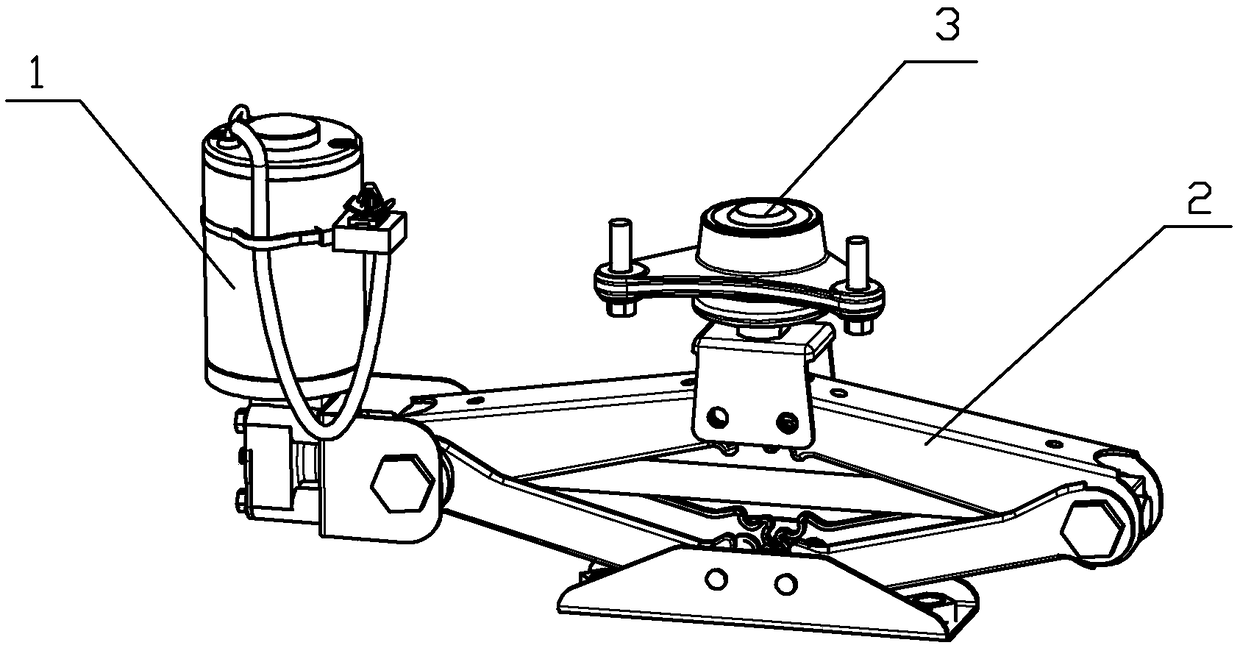

[0023] Embodiment: The lift-type battery frame of this embodiment that promotes the space for battery replacement of electric vehicles, such as figure 1 , figure 2 As shown, the battery frame 18 is installed at the chassis of the electric vehicle 17, and includes a base plate 21 for placing the power battery 20 of the electric vehicle. The front side and the rear side of the base plate are each connected with a coaming plate 22 perpendicular to the base plate. There are and The partition plate 23 parallel to the enclosure, the left side and the right side of the bottom plate respectively have a crossbeam 24, and the crossbeam links to each other with the top surface of the enclosure and the partition. There are four power battery placement areas 25 on the base plate, two of which are located between the partition board and the front side panel according to the left and right distribution, and the other two are located between the partition board and the rear side panel accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com