A silt foundation material and a method for using the foundation material to construct a roadbed

A silt foundation and silt technology, applied in the field of road engineering construction, can solve the problems of high rigidity of road matrix, poor crack resistance, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

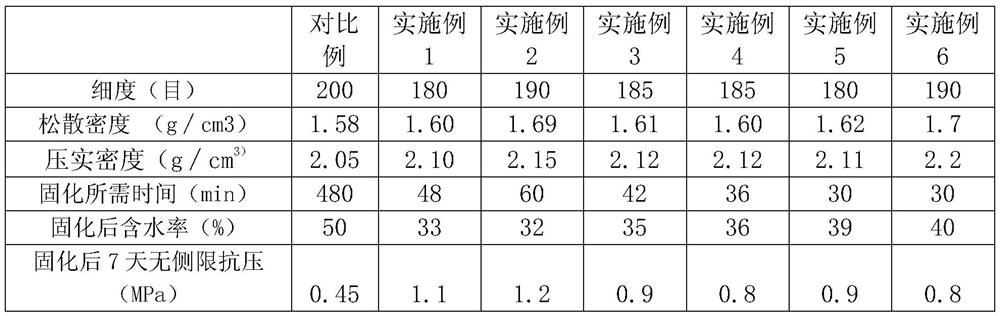

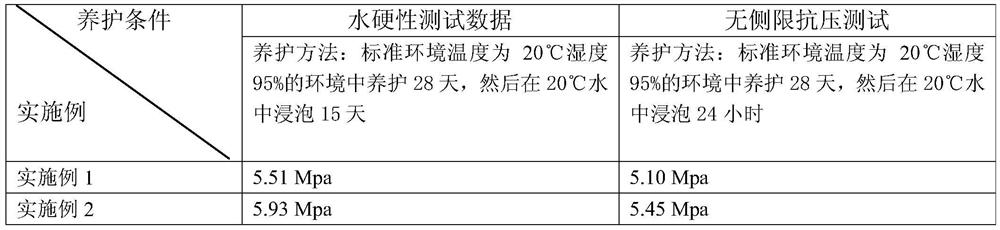

Embodiment 1

[0037] Embodiment 1 is a method for constructing roadbeds with silt foundation materials, characterized in that the specific steps are as follows:

[0038] (1) according to the formula preparation sludge solidifying agent of following mass percent: 25% slag, 21% modified diatomite, 22% attapulgite, 10% microsilica, 4% powder activated carbon, 7.5% potassium peroxide, 2% potassium permanganate, 1.5% iron powder, 3% polyrotaxane, 3% sodium polyacrylate, 0.5% calcium hydroxide, 0.3% naphthalene superplasticizer, 0.2% polyacrylamide, mix and stir the above raw materials Uniformly obtain sludge curing agent;

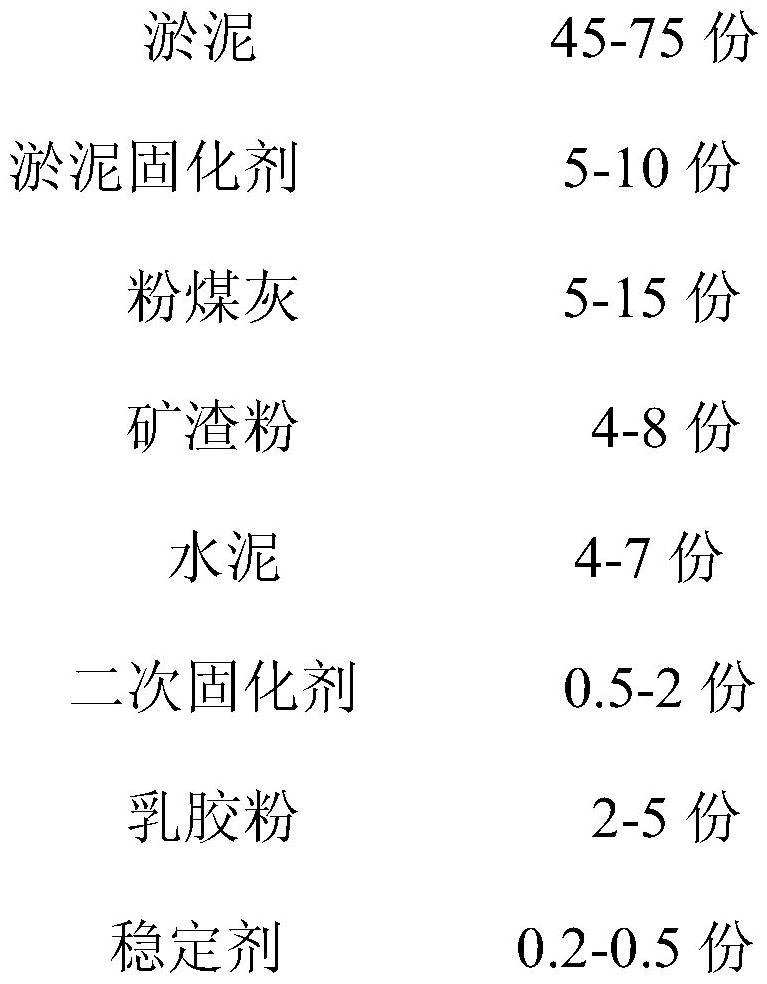

[0039] (2) prepare the raw material of foundation material according to following formula: 74 parts of silt, 10 parts of silt curing agent in step (1), 5 parts of fly ash, 4 parts of slag powder, 4 parts of cement, 0.8 part of curing agent, latex powder 2 parts, 0.2 parts of stabilizer;

[0040] (3) After getting 74 parts of silt and 10 parts of silt solidifying agent in st...

Embodiment 2

[0043] Embodiment 2 A method of constructing a roadbed with silt foundation materials, is characterized in that the specific steps are as follows:

[0044] (1) according to the formula preparation sludge solidifying agent of following mass percent: 20% slag, 23% modified diatomite, 21% attapulgite, 14% microsilica, 6% powder activated carbon, 6% magnesium peroxide, 1% potassium permanganate, 1% iron powder, 2% cationic chelate, 3% polyrotaxane, 2.4% sodium polyacrylate, 0.3% sodium silicate, 0.2% naphthalene superplasticizer, 0.1% polypropylene For amides, the above-mentioned raw materials are fully mixed and stirred in a mixer; the cationic chelate is formed by chelating ethylenediaminetetraacetic acid (EDTA) and calcium ions.

[0045] (2) Prepare the raw materials of the foundation material according to the following formula: 60 parts of silt, 8 parts of silt curing agent in step (1), 9.5 parts of fly ash, 10 parts of slag powder, 8 parts of cement, 1.2 parts of curing agent...

Embodiment 3

[0049] Embodiment 3 provides a method for constructing roadbeds with silt foundation materials, which is characterized in that the specific steps are as follows:

[0050] (1) According to the formula preparation sludge solidifying agent of following mass percentage: at first according to the material preparation raw material of following mass percentage: 15% slag, 24% modified diatomite, 20% attapulgite, 15% microsilica, 8 % powdered activated carbon, 5% calcium peroxide, 2% potassium permanganate, 2.2% iron powder, 4% cationic chelate, 1.5% polyrotaxane, 2% sodium polyacrylate, 0.6% calcium hydroxide, 0.4% naphthalene It is a high-efficiency water reducer and 0.3% polyaluminum chloride. The above-mentioned raw materials are fully mixed and stirred in a mixer; the cationic chelate is formed by chelating dihydroxyethylglycine (DEG) and magnesium ions.

[0051] (2) prepare the raw material of foundation material according to following formula: 65 parts of silt, 8 parts of silt c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com