Sludge solidifying agent and its preparation method and application

A curing agent and sludge technology, applied in the field of sludge curing agent and its preparation, can solve the problems of complex composition, long processing time, landfill engineering geological disasters, etc., achieve unique dispersion, strong water absorption, and improve the effect of sludge characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

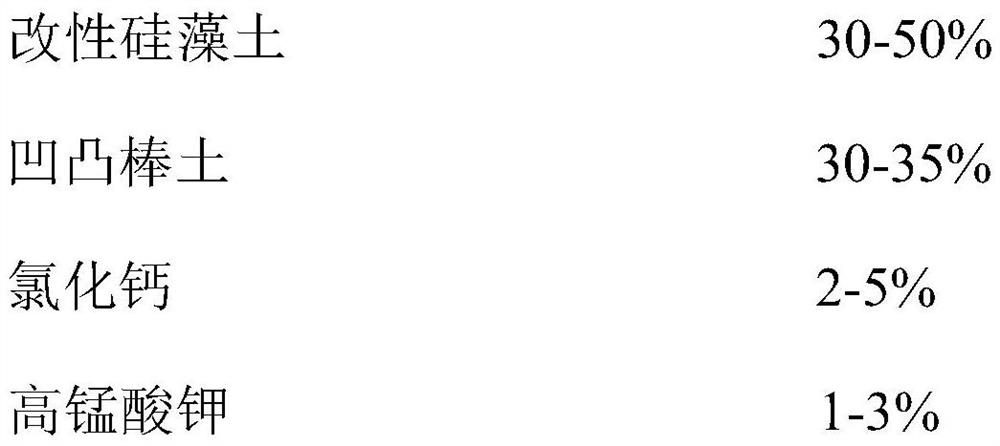

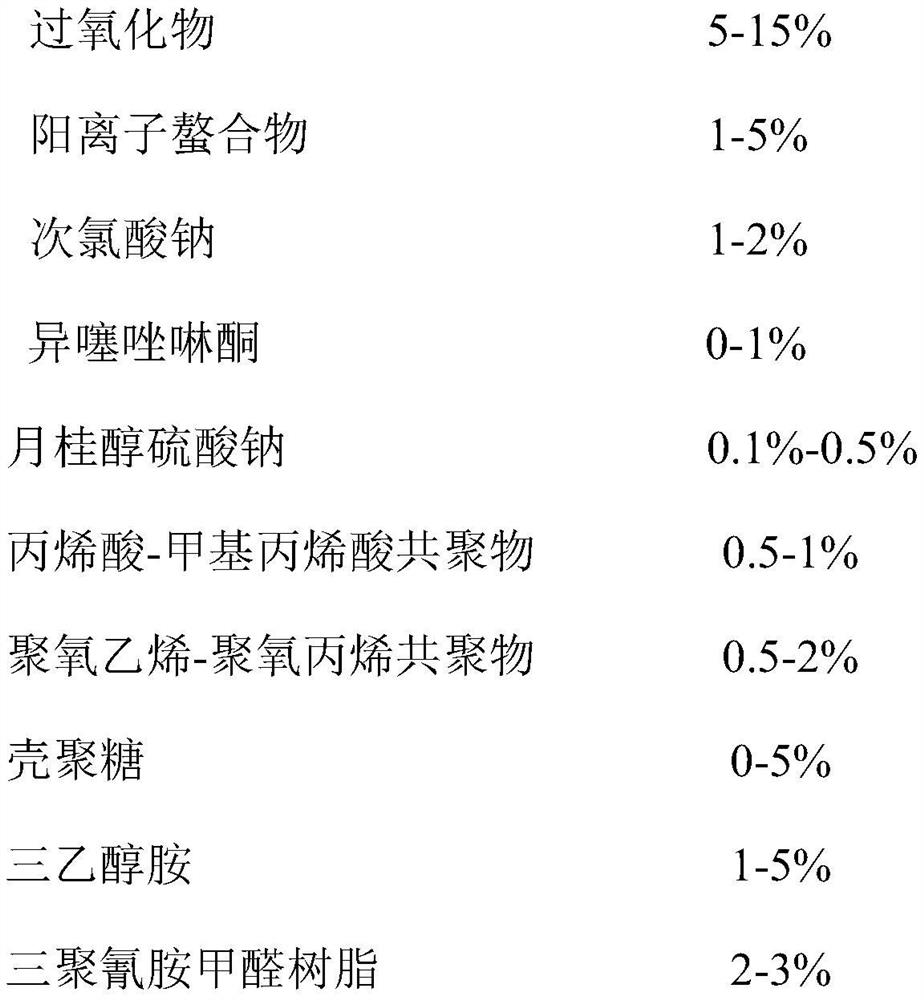

Embodiment 1

[0032] A preparation method of a sludge solidifying agent, comprising the following steps: (1) selecting raw materials according to the following weight percentages, for subsequent use: 30% of modified diatomite, 35% of attapulgite, 5% of calcium chloride, 3% of potassium permanganate %, sodium peroxide 15%, cationic chelate 5%, sodium hypochlorite 2%, sodium lauryl sulfate 0.1%, acrylic acid-methacrylic acid copolymer 0.5%, polyoxyethylene-polyoxypropylene copolymer 1.4%, three 1% ethanolamine, 2% melamine formaldehyde resin; (2) fully mix and stir the above raw materials in a mixer. The cationic chelate is formed by chelating ethylenediaminetetraacetic acid (EDTA) and magnesium ions.

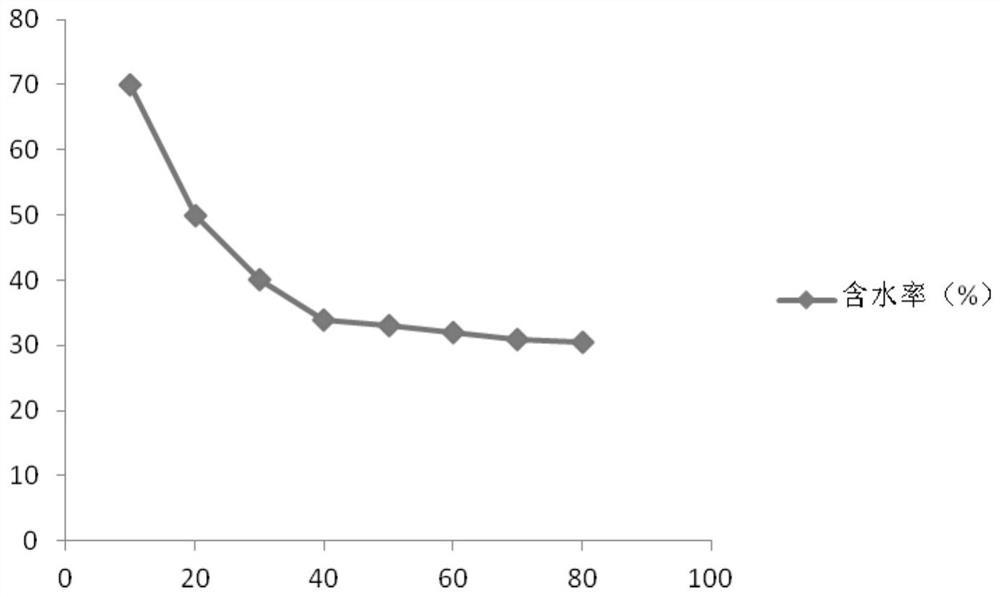

[0033] The application method of the silt curing agent comprises the steps of: adding the curing agent into the silt according to the mixing ratio of 38%: 1 in the mass ratio of the curing agent to the silt, then fully mixing, and then drying and curing naturally for 0.5h be usable.

Embodiment 2

[0035] A preparation method of a sludge solidifying agent, comprising the steps of: (1) selecting raw materials according to the following weight percentages, for subsequent use: 35% of modified diatomite, 32% of attapulgite, 4% of calcium chloride, 2% of potassium permanganate %, calcium peroxide 10%, strontium peroxide 2%, cationic chelate 4%, sodium hypochlorite 1.8%, isothiazolinone 0.2%, sodium lauryl sulfate 0.2%, acrylic acid-methacrylic acid copolymer 0.6%, poly 1% of oxyethylene-polyoxypropylene copolymer, 3.2% of chitosan, 1.8% of triethanolamine, 2.2% of melamine formaldehyde resin; (2) fully mixing and stirring the above raw materials in a mixer.

[0036] The cationic chelate is formed by chelating dihydroxyethylglycine (DEG) and calcium ions.

[0037] The application method of the sludge curing agent comprises the steps of: adding the curing agent into the sludge according to the mixing ratio of the curing agent and the sludge mass ratio of 30%: 1, then fully mixi...

Embodiment 3

[0039]A preparation method of a sludge solidifying agent, comprising the following steps: (1) selecting raw materials according to the following weight percentages, for subsequent use: modified diatomite 38%, attapulgite 34%, calcium chloride 3%, potassium permanganate 1 %, Magnesium peroxide 6%, Potassium monopersulfate 4%, Cationic chelate 3%, Sodium hypochlorite 1.5%, Isothiazolinone 0.4%, Sodium lauryl sulfate 0.3%, Acrylic acid-methacrylic acid copolymer 0.7% , 0.8% of polyoxyethylene-polyoxypropylene copolymer, 1.8% of chitosan, 3% of triethanolamine, 2.5% of melamine formaldehyde resin; (2) fully mixing and stirring the above-mentioned raw materials in a mixer. The cationic chelate is formed by chelating dihydroxyethylglycine (DEG) and magnesium ions.

[0040] The application method of the silt curing agent comprises the steps of: adding the curing agent into the silt according to the mixing ratio of 22%:1 according to the mass ratio of the curing agent and the silt; b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com