Garbage fermentation process

A fermentation process and waste technology, applied in the direction of organic fertilizer, climate change adaptation, etc., can solve the problem of low quality of organic fertilizer, and achieve the effect of increasing beneficial components and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

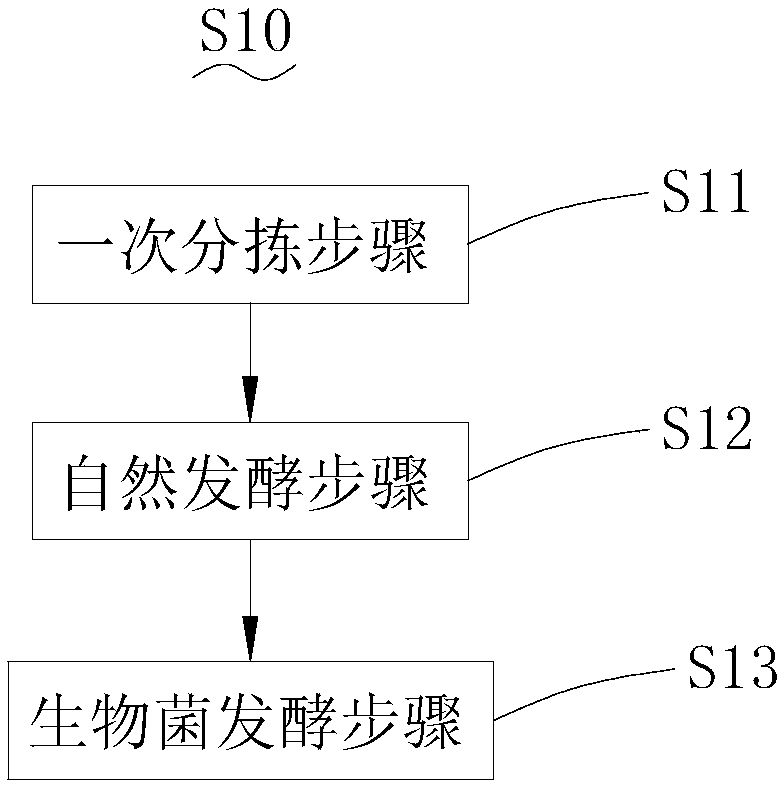

[0023] see figure 1 , the embodiment of the present invention provides a garbage fermentation process S10, comprising the following steps:

[0024] A sorting step S11, using a sorting mechanism to sort the garbage, and sort out the garbage containing 15%-20% of non-dissolved organic matter;

[0025] Natural fermentation step S12, performing natural fermentation on the garbage containing 15%-20% non-dissolved organic matter to obtain fermentation intermediate products;

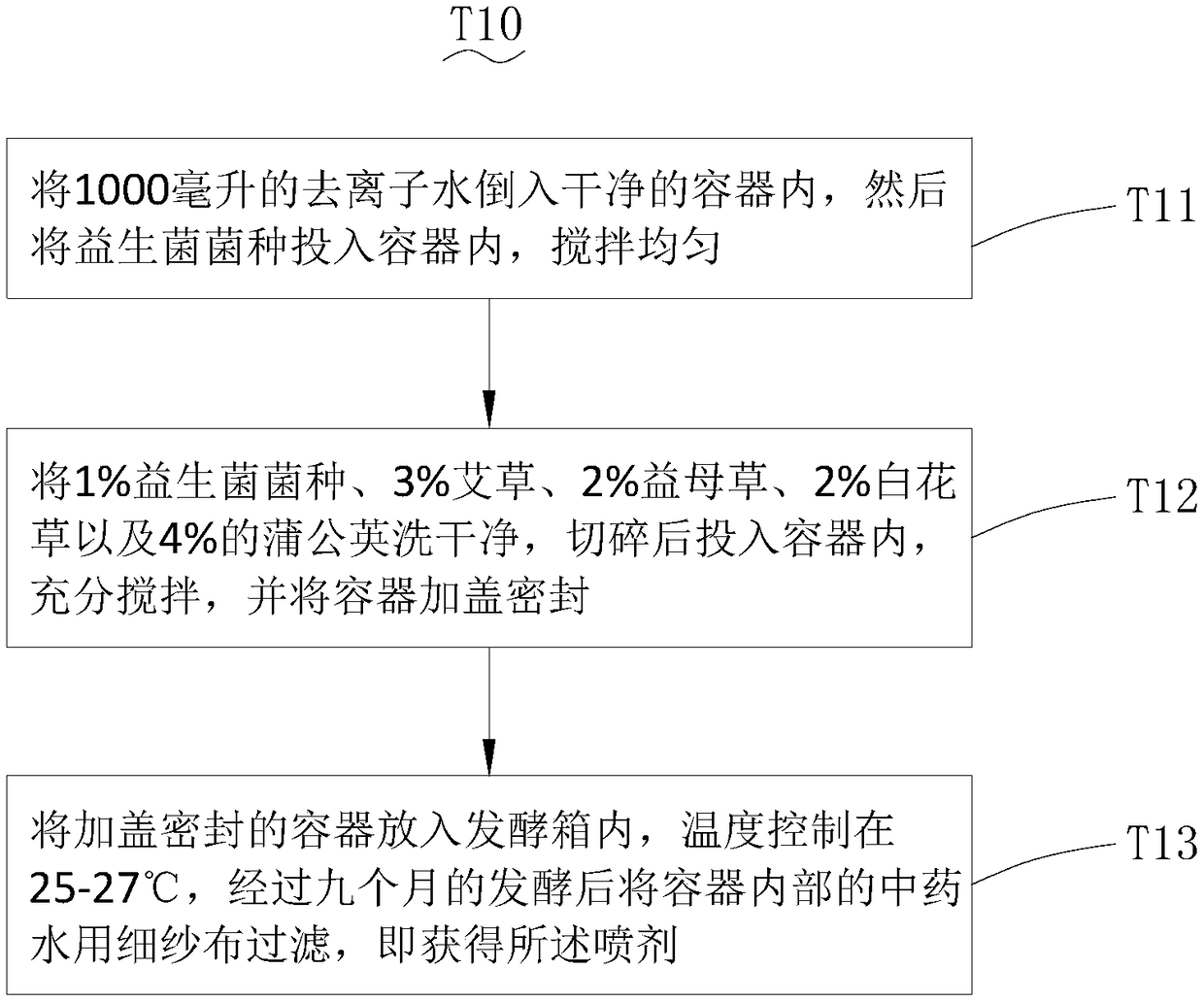

[0026] Bio-bacteria fermentation step S13, adding a spray containing probiotic strains to the fermentation intermediate product to carry out bio-bacteria fermentation to obtain an org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com