Pollution-free, environment-friendly and clean garbage disposal method capable of by-producing fertilizer

A technology of garbage treatment and garbage treatment equipment, which is applied in the field of garbage treatment that is non-polluting, environmentally friendly and clean, and produces by-product fertilizers. It can solve the problems of low utilization rate of treatment liquid and cumbersome steps, and achieve saving of landfill leachate, simple operation and convenient treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

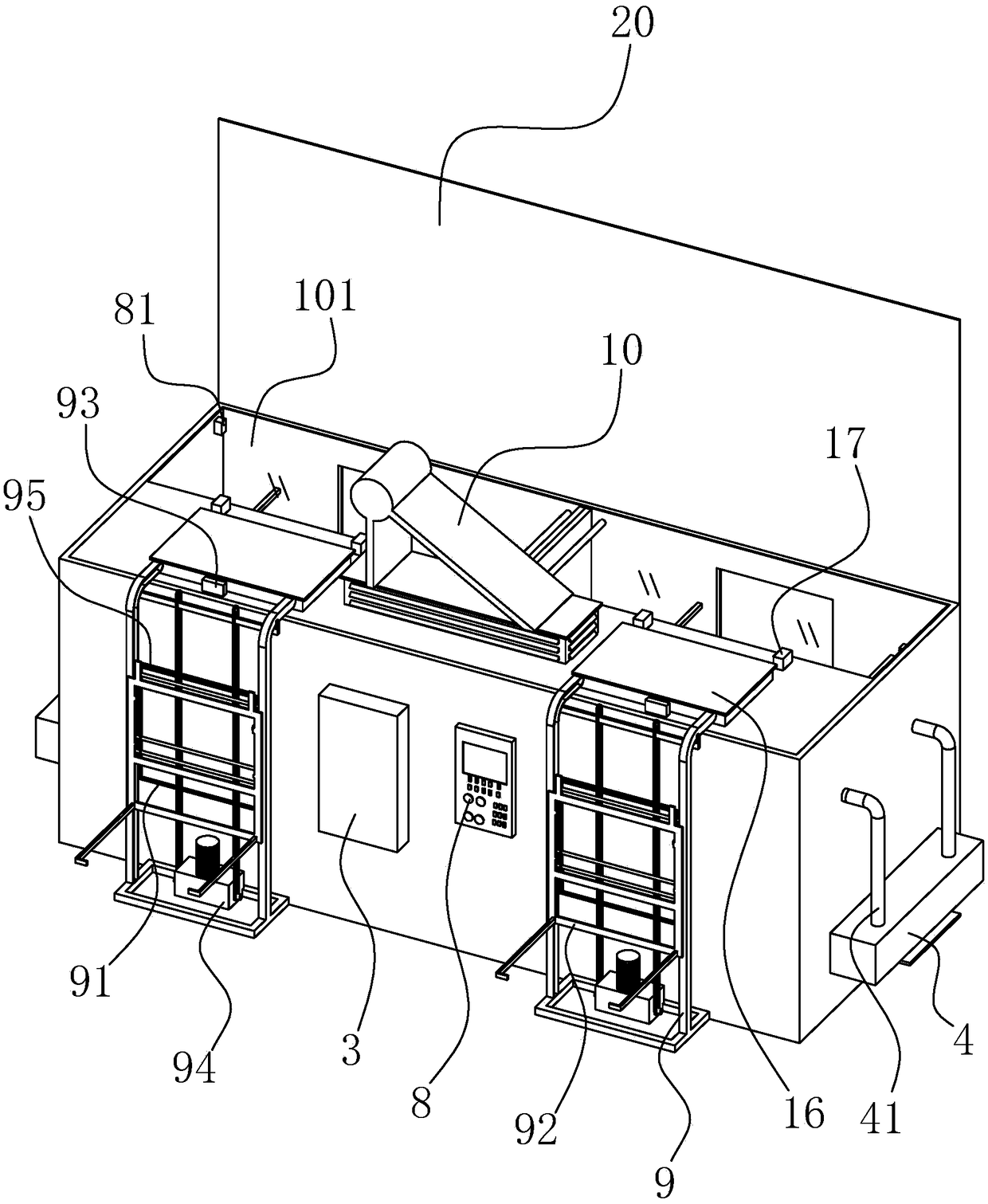

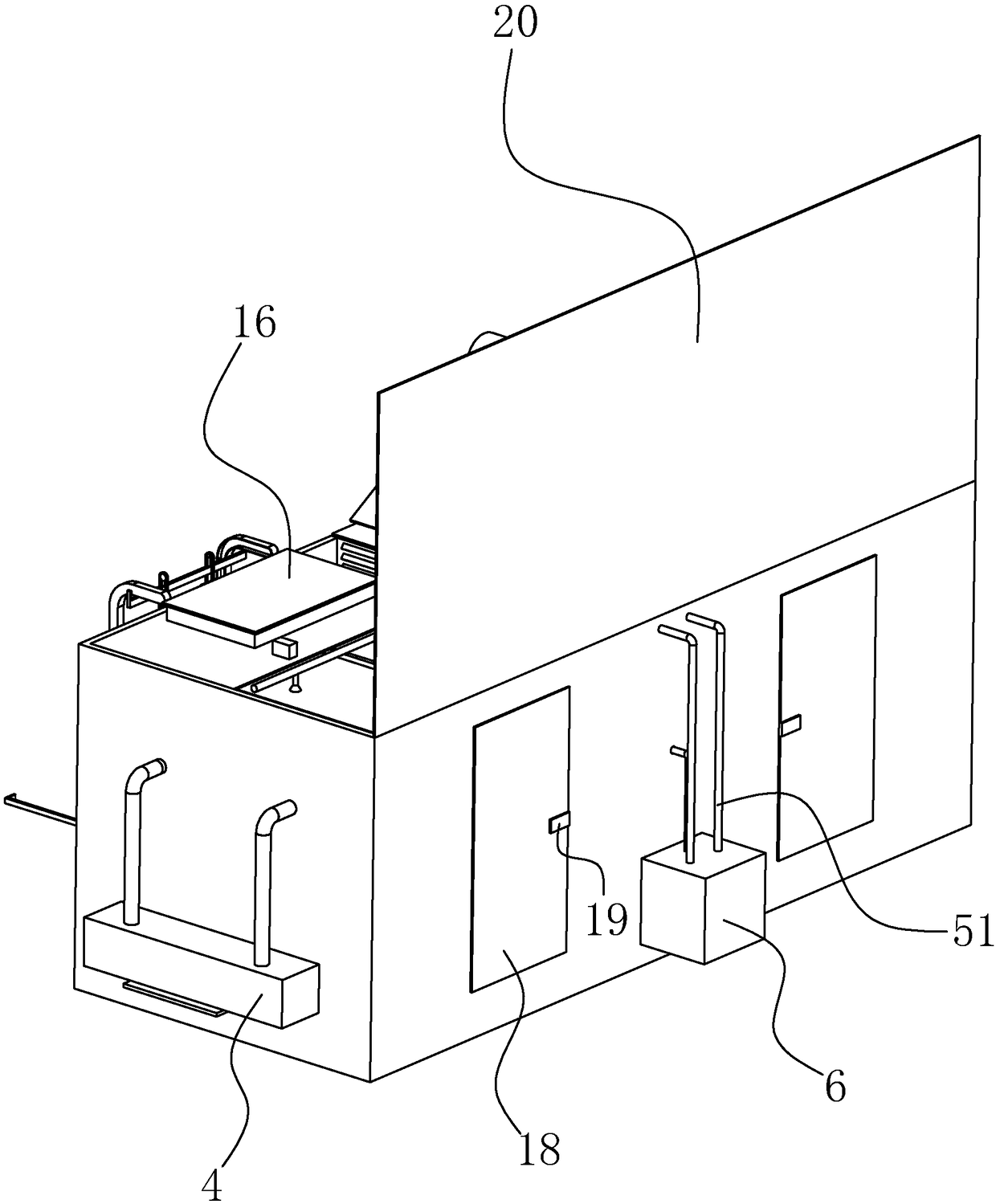

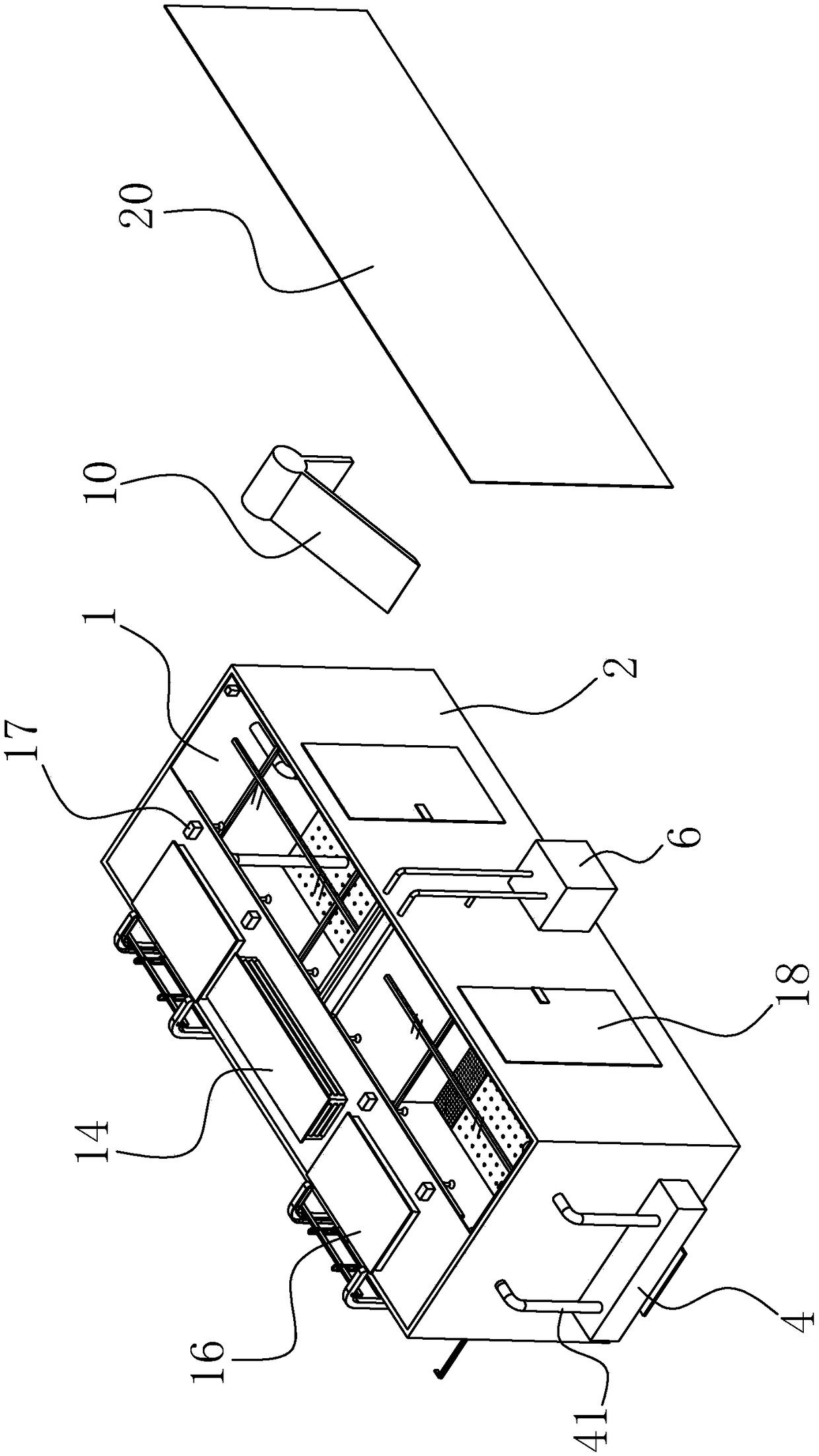

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0035] Such as Figure 1 to Figure 13 As shown, the pollution-free, environmentally friendly, clean and by-product fertilizer garbage disposal method of the present embodiment comprises the following steps,

[0036]1. Pour the garbage into the garbage disposal device, make the garbage accumulate in the inner cavity of the garbage disposal device, and seal the garbage feeding port 11;

[0037] 2. Spray the landfill leachate that can decompose the waste on the accumulated waste, so that the accumulated waste will be heated and decomposed in the waste treatment device under the action of the landfill leachate;

[0038] 3. Keep the temperature of the inner cavity of the garbage disposal device at 40-70°C, so that the garbage can continue to rot and ferment in the inner cavity of the garbage disposal device;

[0039] 4. The liquid in the garbage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com