Cyclic spray control method and washing machine

A cycle spraying and control method technology, applied in the field of washing machines, can solve the problems of waste of water resources and increase costs, and achieve the effects of reasonable program control, reduction of waste of water resources, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

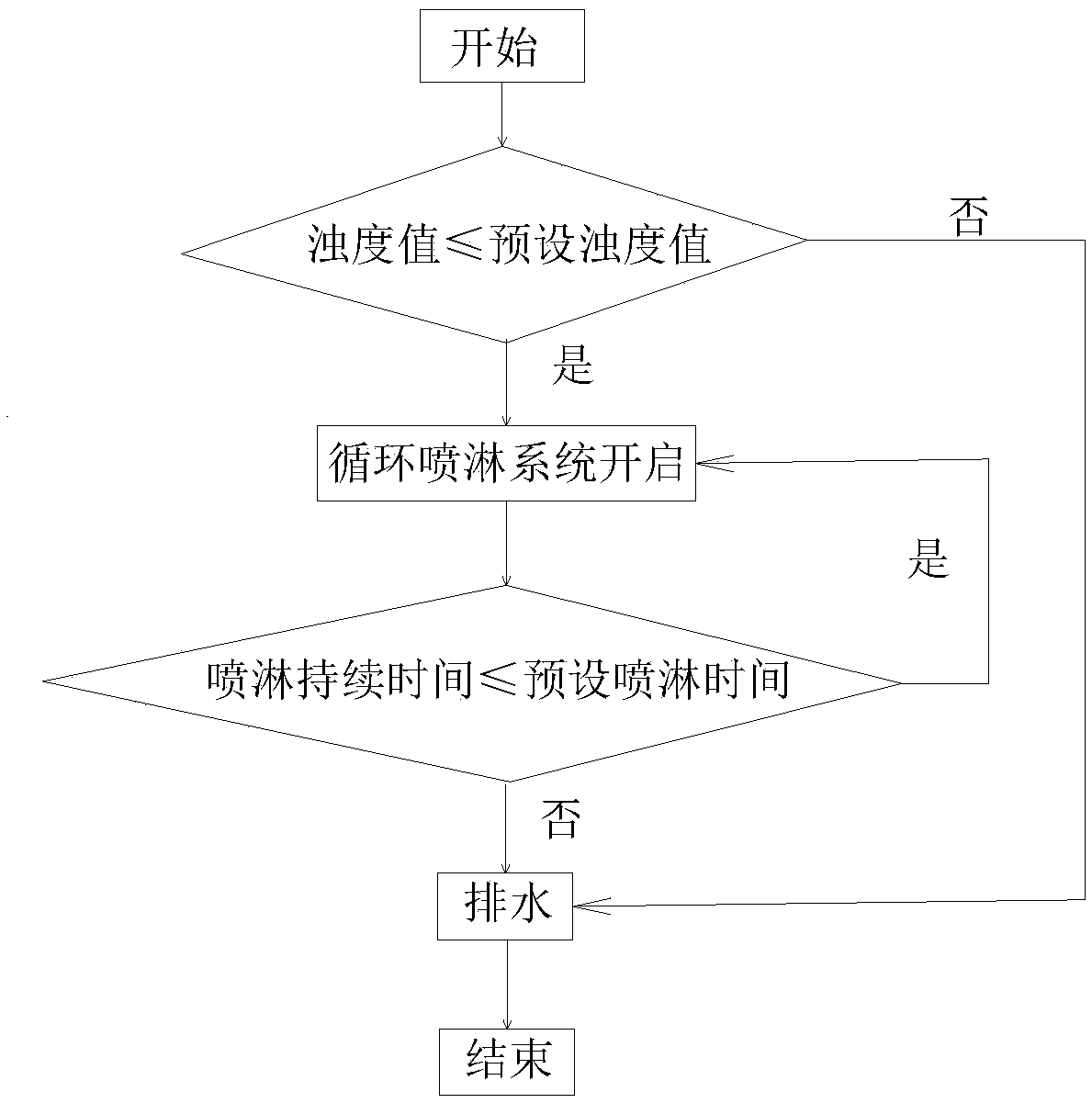

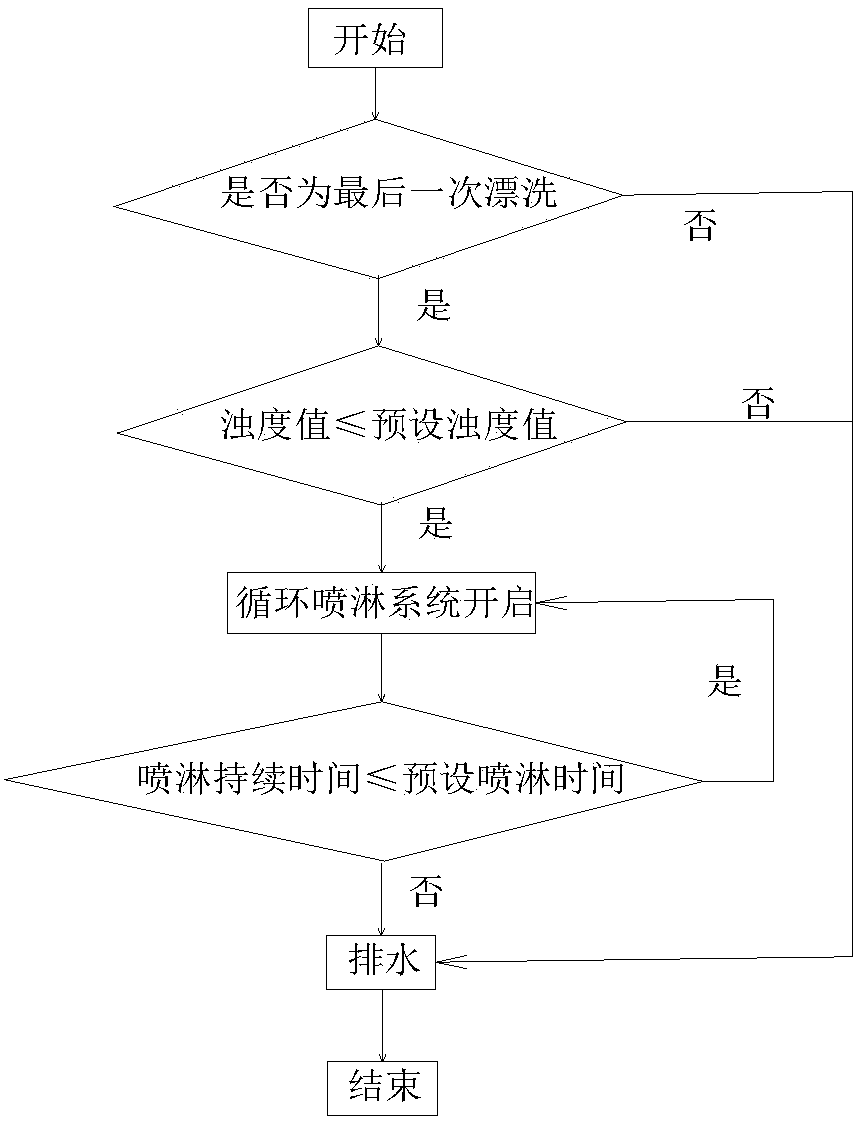

[0066] On the basis of Embodiment 1, the washing machine in this embodiment also includes a detection unit 23 for detecting the turbidity value of the laundry water, and the control method further includes the detection unit 23 detecting the turbidity value of the laundry water in the washing and / or rinsing program. Turbidity value, the washing machine controls the opening of the circulating spraying system according to the detected turbidity value.

Embodiment 1

[0067] In the first embodiment, the cycle spraying is carried out at a fixed time node through the program (such as after the last rinsing and before draining). This control method performs cycle spraying at the above time node no matter for the dirty clothes or the clean clothes. Showering, though it can be realized to use washing water as the spray water for rinsing and washing, it is too stylized and has poor flexibility. By setting the detection unit 23 for detecting the turbidity of the laundry water, the washing machine judges whether to open the circulating spray system according to the turbidity value of the laundry water detected by the detection unit 23. When the turbidity value is small enough to perform better cleaning, the washing machine is turned on The circulating spraying system makes the control more intelligent and precise. The detection unit 23 can detect at any time during the washing and / or rinsing procedure, during water intake, rinsing, washing or drain...

Embodiment 3

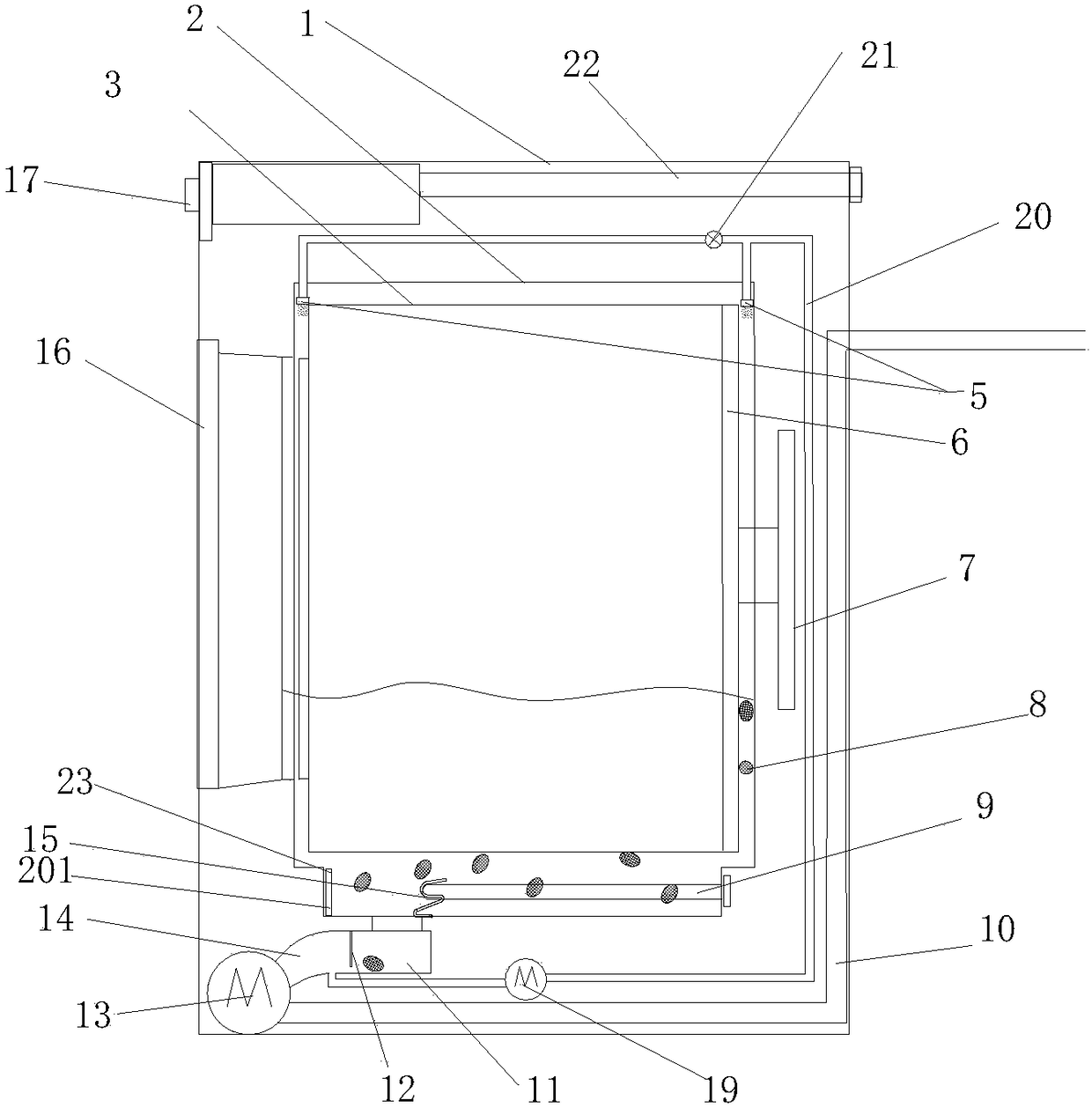

[0093] like Figure 3-11 As shown, the present embodiment is a washing machine adopting the cycle spray control method of Embodiment 1 or Embodiment 2. The washing machine is a drum washing machine, and the bottom of the washing machine is provided with a drainage pipeline 10 and a cycle spray system. The system includes an internal circulation pipe 20, a circulation pump 19 arranged on the internal circulation pipe 20, and a spray head assembly 5. The water inlet end of the internal circulation pipe 20 communicates with the lower part of the outer cylinder and / or with the drainage pipeline 10, and the other end communicates with the spray head assembly 5 connected. When the washing machine controls the circulation spray system to open, the washing machine controls the circulation pump 19 to open, and the laundry water is pumped to the nozzle assembly 5 through the inner circulation pipe 20, and the inner wall and / or the outer wall of the inner cylinder are realized according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com