A replaceable partially filled composite structure frame assembly node and its preparation method

A technology of frame assembly and combined structure, which is applied to building components, building structures, protective buildings/shelters, etc., can solve the problems of reduced out-of-plane stiffness of steel beams, out-of-plane buckling of steel beams, and reduced fatigue life, etc. Achieve the effect of solving out-of-plane buckling, good local buckling, convenient connection and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

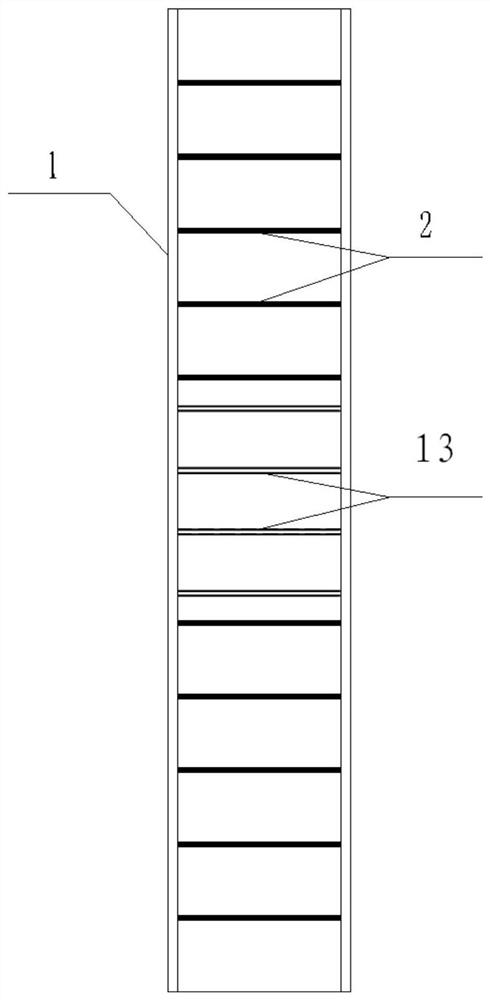

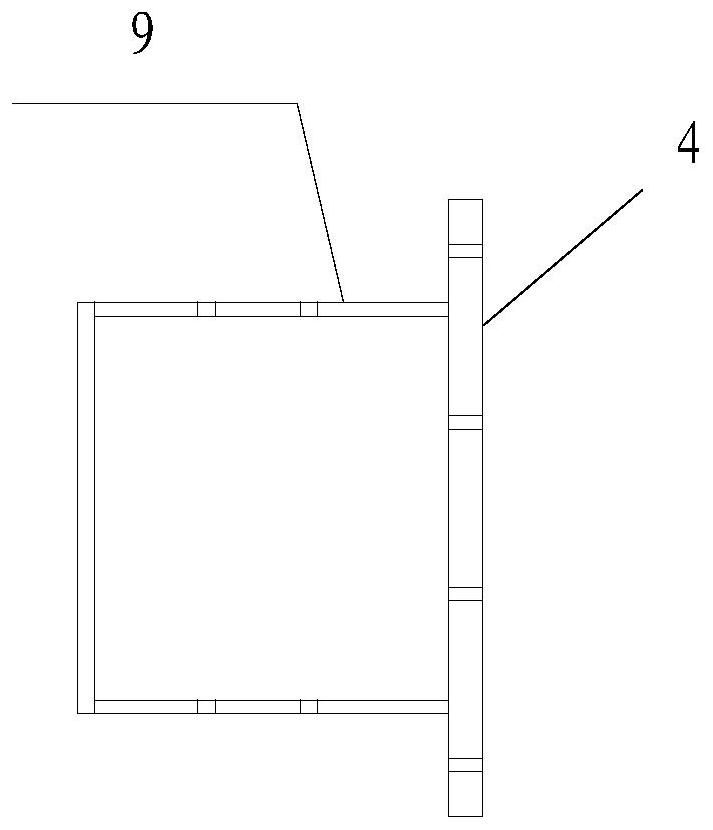

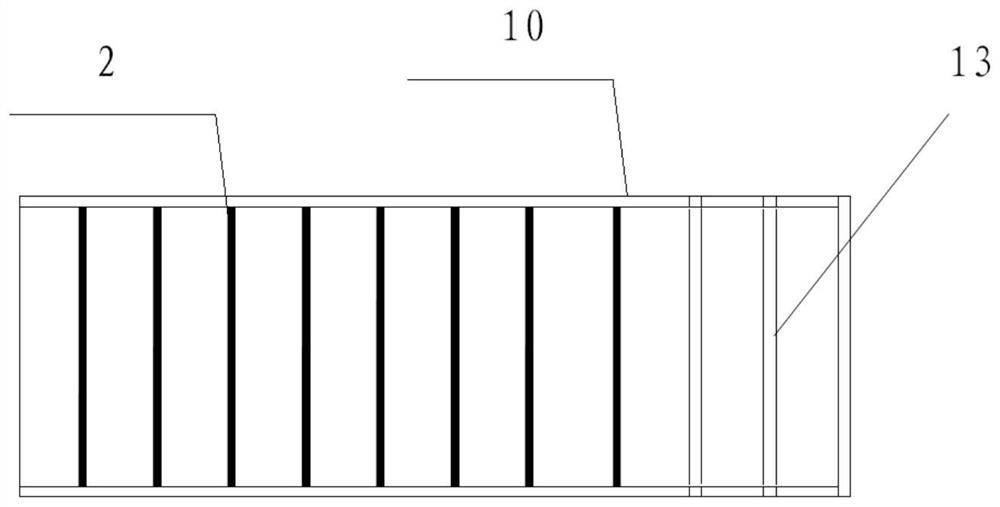

[0047] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , the present invention provides a replaceable energy-dissipating beam section partly filled combined structure frame assembled node, the assembled node is mainly composed of partly filled column 1 and partly filled beam 5, wherein the partly filled beam 5 is divided into are the first partially filled beam segment, the second partially filled beam segment and the partially filled energy dissipation beam segment. The first partially filled beam section includes a first H-shaped steel section with an end plate 4 at one end, and the other end of the first H-shaped steel section has a sealing plate ( figure 2 middle left side), and there are through mounting holes for tension bolts on the flanges on both sides (the mounting holes are arranged symmetrically along the web 14), the flanges on both sides of the first H-shaped steel section and the sealing plate ( figure 2 Middle left...

Embodiment 2

[0060] see figure 1 , Figure 8 , Figure 9 , Figure 10 and Figure 11 , the present invention provides a replaceable beam structure partially filled composite structure frame assembled node, the assembled node is mainly composed of partially filled column 1 and partially filled beam 5, partially filled column 1 and partially filled beam 5. It is connected by the tension bolts 3 located in the node area in the partially filled column 1. Both sides of the H-shaped steel web of the partially filled column 1 are poured with concrete 8, and the tension bolts 3 are symmetrically arranged on the H section of the partially filled column 1. Both sides of the section steel web run through the filled concrete and the flanges on both sides, that is, the partially filled column 1 can be connected to two partially filled beams 5 on both sides of it at the same time; the partially filled beam 5 is connected to the partially filled column 1 An end plate 4 is welded to facilitate the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com