Height-adjustable safety ladder cage composite device for engineering

A combined device and adjustable technology, which is used in the erection/assembly of bridges, bridges, and on-site preparation of building components, can solve problems such as safety accidents, dizziness, and fear of going up and down the safety ladder cage, and achieves a guaranteed safety index. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

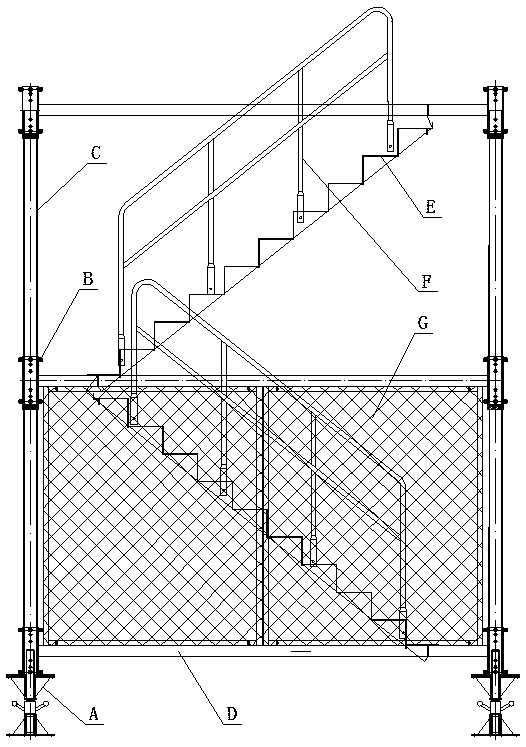

[0052] as attached figure 1 As shown, the present invention provides a height-adjustable safety ladder cage combination device for engineering, the structure of which includes a fixedly connected safety ladder cage and a height-adjustable component A.

[0053] The safety ladder cage also includes:

[0054] A ladder cage frame formed by a plurality of vertically arranged columns C and a plurality of horizontally arranged beams D is fixedly connected,

[0055]A plurality of safety ladders E arranged inside the cage frame. The safety ladder E is a closed staircase structure formed by connecting the first positions of multiple L-shaped pedals in sequence.

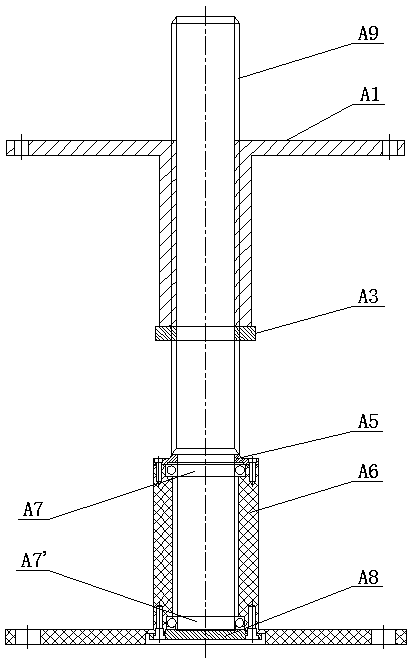

[0056] combined with figure 2 , the height-adjustable component A further includes:

[0057] Vertically arranged adjusting lead screw A9;

[0058] The fixed base A6 is sleeved on the outer side of the lower part of the adjustment screw A9, the adjustment screw A9 is connected to the fixed base A6 through the upper bearing ...

Embodiment 2

[0073] combined with Figure 7 , on the basis of the structure of Embodiment 1, a handle A4 is also fixed in the middle of the adjustment screw A9 involved, and the handle A4 is located below the lock nut A3. By turning the handle A4, the adjustment screw A9 is directly driven to rotate, which is convenient to use.

[0074] The T-shaped outer surface of the involved movable top seat A1 is arranged with a plurality of upper reinforcing ribs A2, which are used to improve the strength of the movable top seat A1 supporting the ladder cage frame upwards, and the outer surface of the fixed base A6 is arranged with a plurality of lower reinforcing ribs A2' is used to strengthen the self-strength of the fixed base A6.

Embodiment 3

[0076] combined with figure 1 , the safety ladder cage involved also includes a stair guard rail F, and the stair guard rail F is arranged on the upper surface of the safety ladder E.

[0077] The involved safety ladder cage also includes a protective net G, which is arranged on opposite sides of the safety ladder E, and the protective net G is in contact with the side of the safety ladder E.

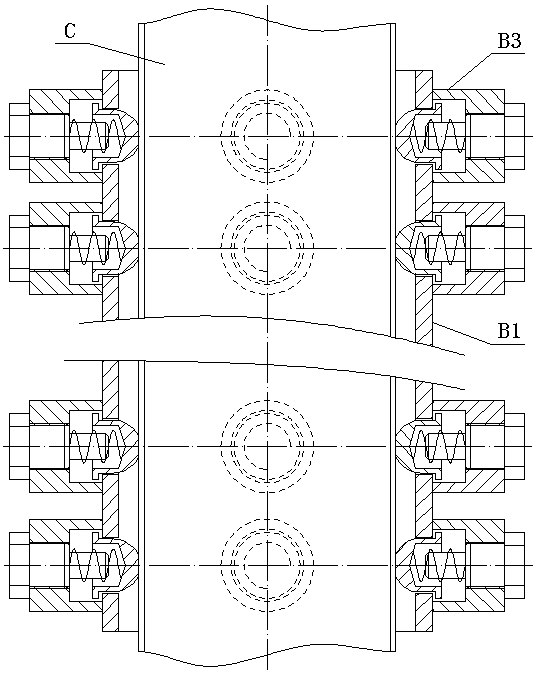

[0078] combined with Figure 6 , in the three embodiments of the present invention, the height-adjustable component A involved is connected with the frame of the ladder cage through the center limit component B of the column, and the adjusting screw A9 extends upward into the limit square tube B1, and by rotating Tighten the bolt B6, adjust the telescopic length of the spring B7, so that the spherical limit head B5 presses against the outer surface of the adjustment screw A9 along the direction of the through hole B2, and under the action of multiple spherical limit heads B5, ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com