Novel temperature-reducing device of temperature-reducing and pressure-reducing valve

A technology of temperature reduction and pressure reduction, pressure reducing valve, applied in safety devices, engine components, machines/engines, etc., can solve problems such as large temperature fusion drop of valve body, valve body crack leakage, safety accidents, etc., and achieve stable production and operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

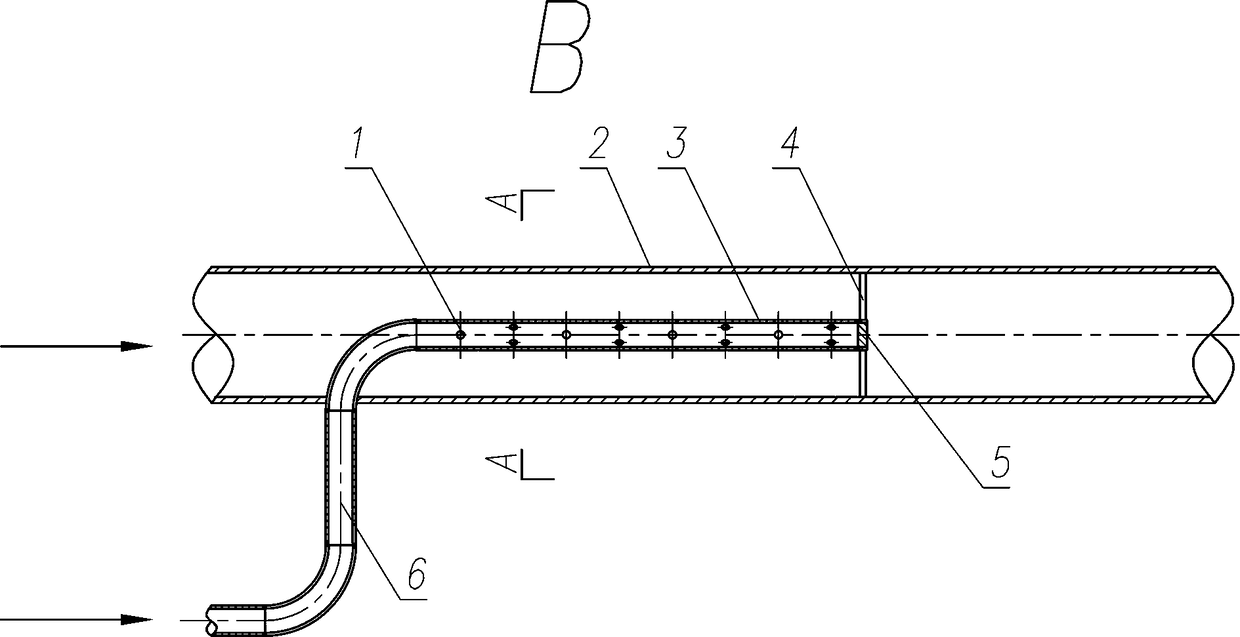

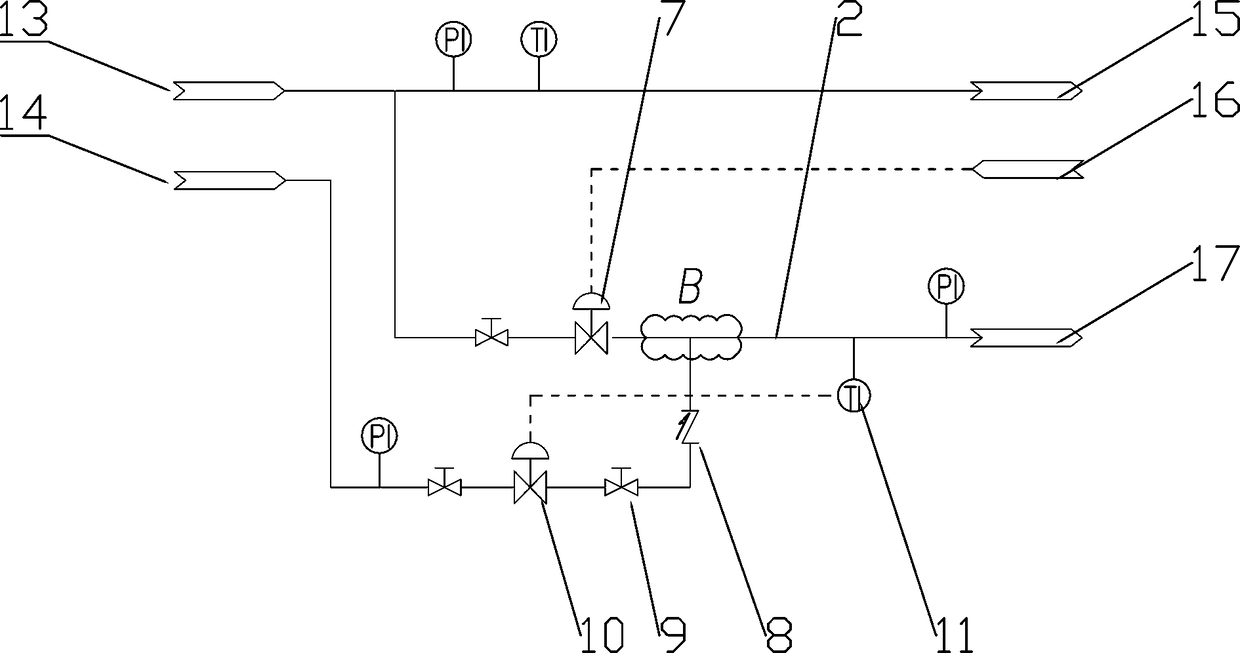

[0014] Such as Figure 1-2 As shown, a new type of desuperheating device for a desuperheating and decompression valve is arranged on the output end of the decompression valve 7, including a spray pipe 3 installed inside the steam pipe 2, and 28 spray pipes are staggered and drilled on the spray pipe 3. The shower holes 1 and the spray holes 1 are equidistantly arranged circularly and interlaced, and the interlaced angle is 45°. This ensures even mixing and rapid cooling. A blind plate 5 is arranged at the end of the spray pipe 3 to form a sealed structure at one end. The end of the spray pipe 3 is installed on the steam pipe 2 through the spray pipe support 4, and is installed concentrically with the steam pipe 2; There are check valve 8, shut-off valve 9, cooling water valve 10. The steam temperature feedback signal is provided by the thermometer behind the decompression valve, so as to control the switch of the cooling water valve 10, adjust the water supply of the sprayi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com