CO2 mixed working medium and CO2 mixed working medium heat pump system

A technology of mixed working fluid and heat pump system, applied in lighting and heating equipment, gas cycle refrigerators, refrigerators, etc., can solve the problems of increasing cost, decreasing durability, increasing the difficulty of equipment design process, etc., to reduce the difficulty and Production cost, risk and impact reduction, mitigation of the effect of too short lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

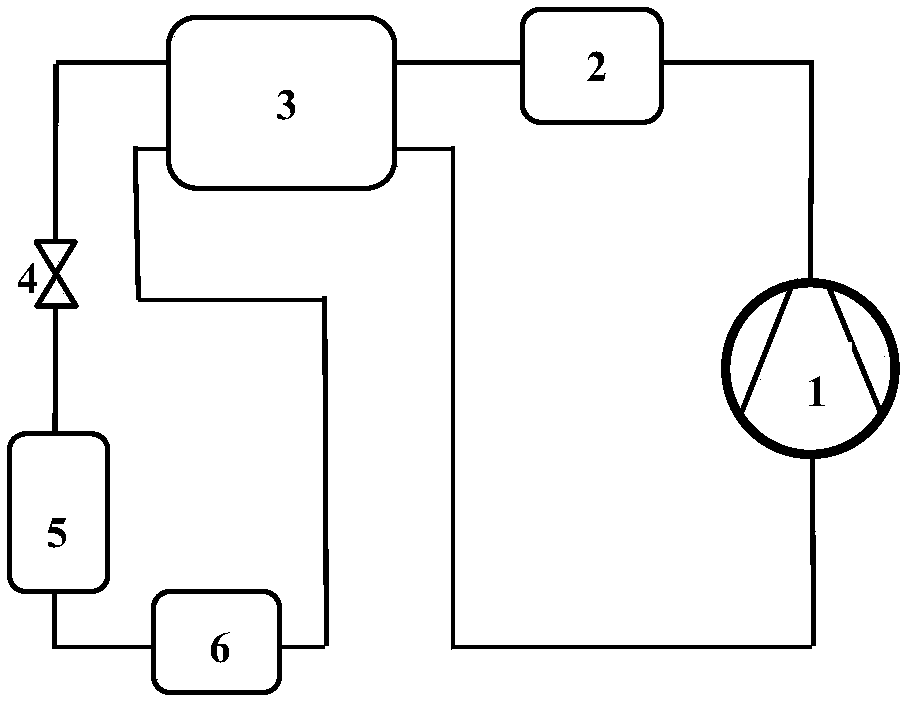

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] The present invention provides a CO 2 mixed working fluid, by CO 2 It is mixed with R290, and the ratio of each component is based on the mass percentage. According to the different outlet water temperature required by the actual working conditions, an appropriate mass fraction ratio can be selected, and the CO 2 The mass fraction of x and the outlet water temperature T of the air cooler gas The functional relation of :

[0025] x=0.0115T gas -0.2178

[0026] Among them: x——CO 2 The mass percentage;

[0027] T gas ——The outlet water temperature of the gas cooler / °C.

[0028] The present invention also provides a method using the above CO 2 Mixed CO 2 The mixed working medium heat pump system includes: compressor 1, gas cooler 2, regenerator 3, throttle valve 4, intermediate liquid storage 5 and evaporator 6; the outlet of compressor 1 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com