Measurement device for coaxiality error of multi-stage rotating body and measurement method

A measuring device and rotating body technology, applied in the field of geometric quantity measurement, can solve problems such as the difficulty in measuring the coaxiality error of multi-stage rotating bodies, and achieve the effects of measurement and compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

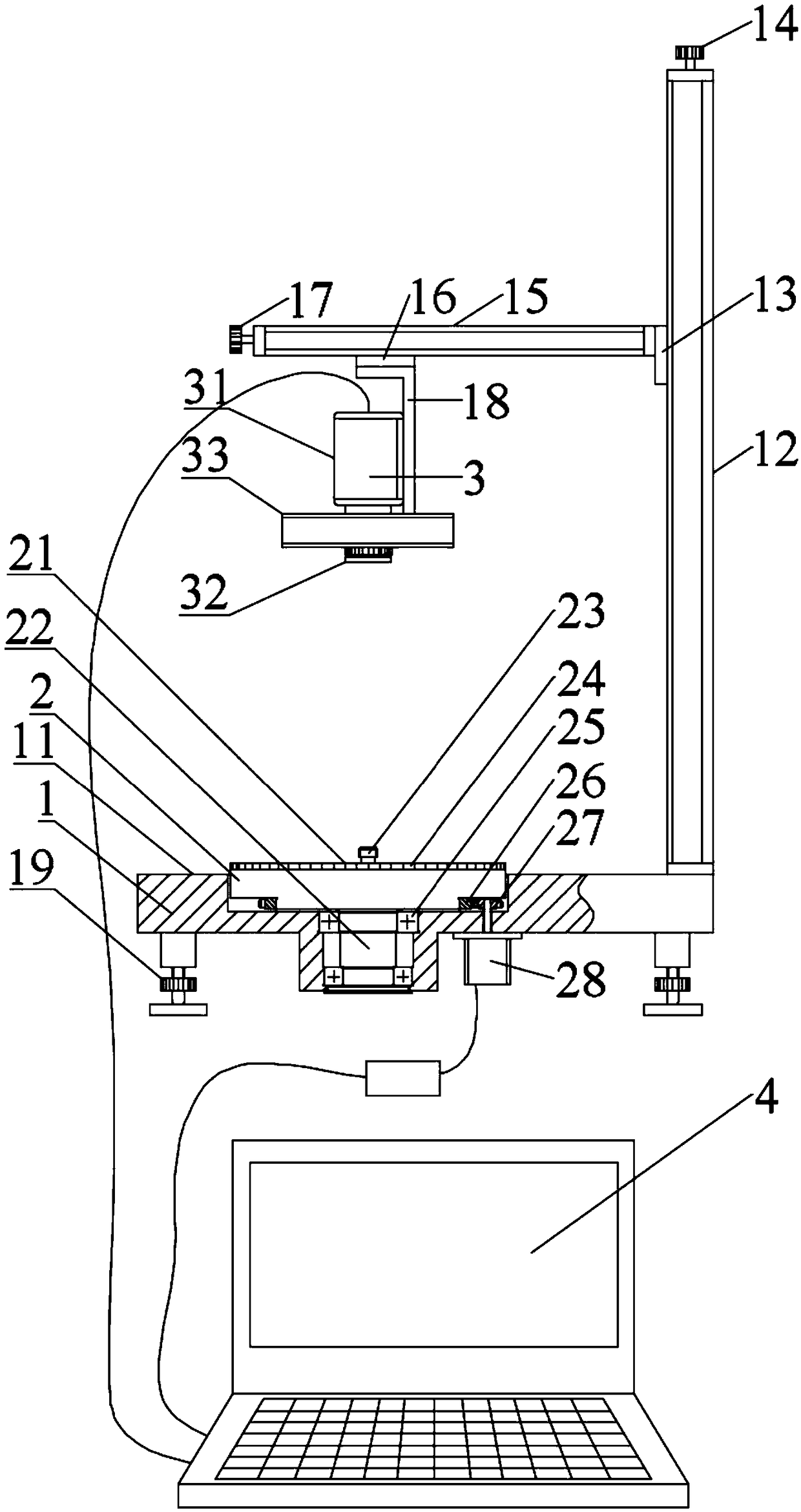

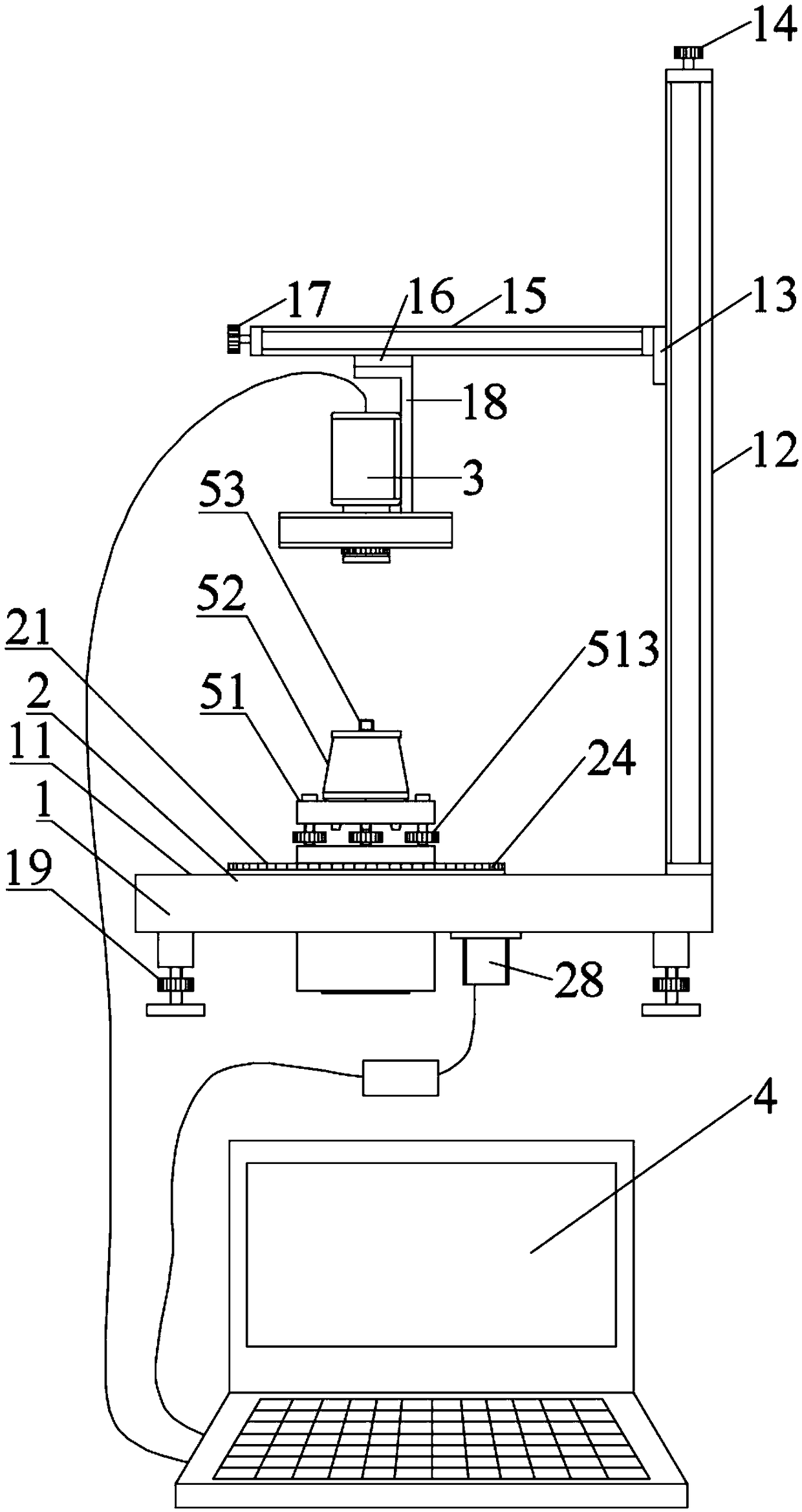

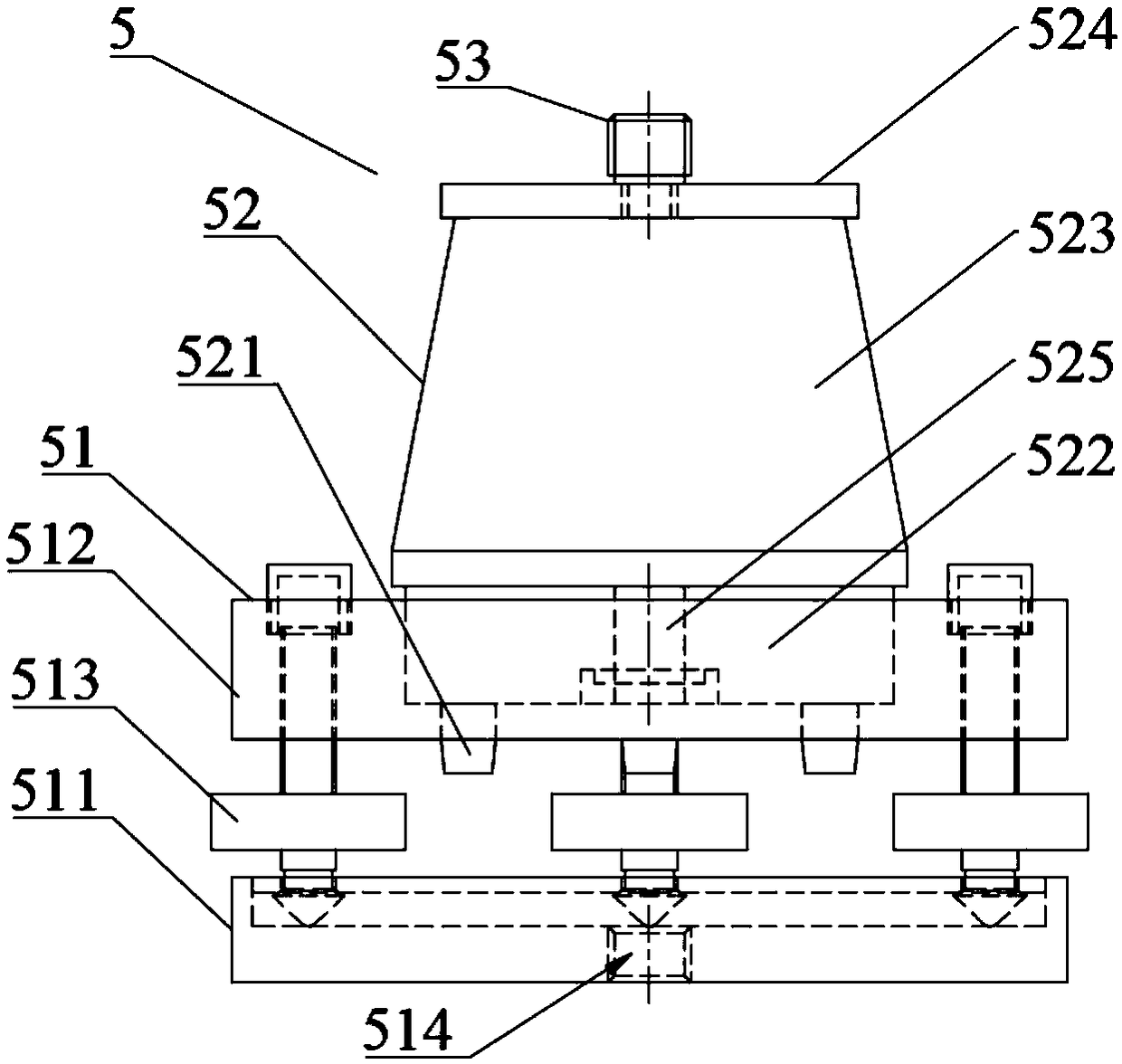

[0033] A measuring device for the coaxiality error of a multi-stage rotating body proposed by the present invention, such as figure 1 As shown, the device includes a support system 1 , a rotation system 2 , a visual measurement system 3 and a computer 4 .

[0034] The support system 1 includes a base 11. At least three sets of lifting and fine-tuning structures 19 are provided on the bottom of the base 11 for accurately leveling the horizontal rotating table 21; a longitudinal linear guide rail 12 is installed on the upper right side of the base 11, so A longitudinal slider 13 is installed on the longitudinal linear guide rail 12, a threaded screw passes through the longitudinal slider 13, a longitudinal control handwheel 14 is connected to the top of the screw, and a horizontal linear guide rail is connected to the longitudinal slider 13 15. A transverse slider 16 is installed on the transverse linear guide rail 15, a threaded screw passes through the transverse slider 16, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com