Low-temperature container and pressure obtaining device for measuring liquid level of low-temperature container

A low-temperature container and liquid level measurement technology, which is applied to the outer wall of container structure, container discharge method, container filling method, etc. Fluctuation and other problems, to achieve the effect of improving stability and accuracy, reducing impact energy, and lengthening the path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

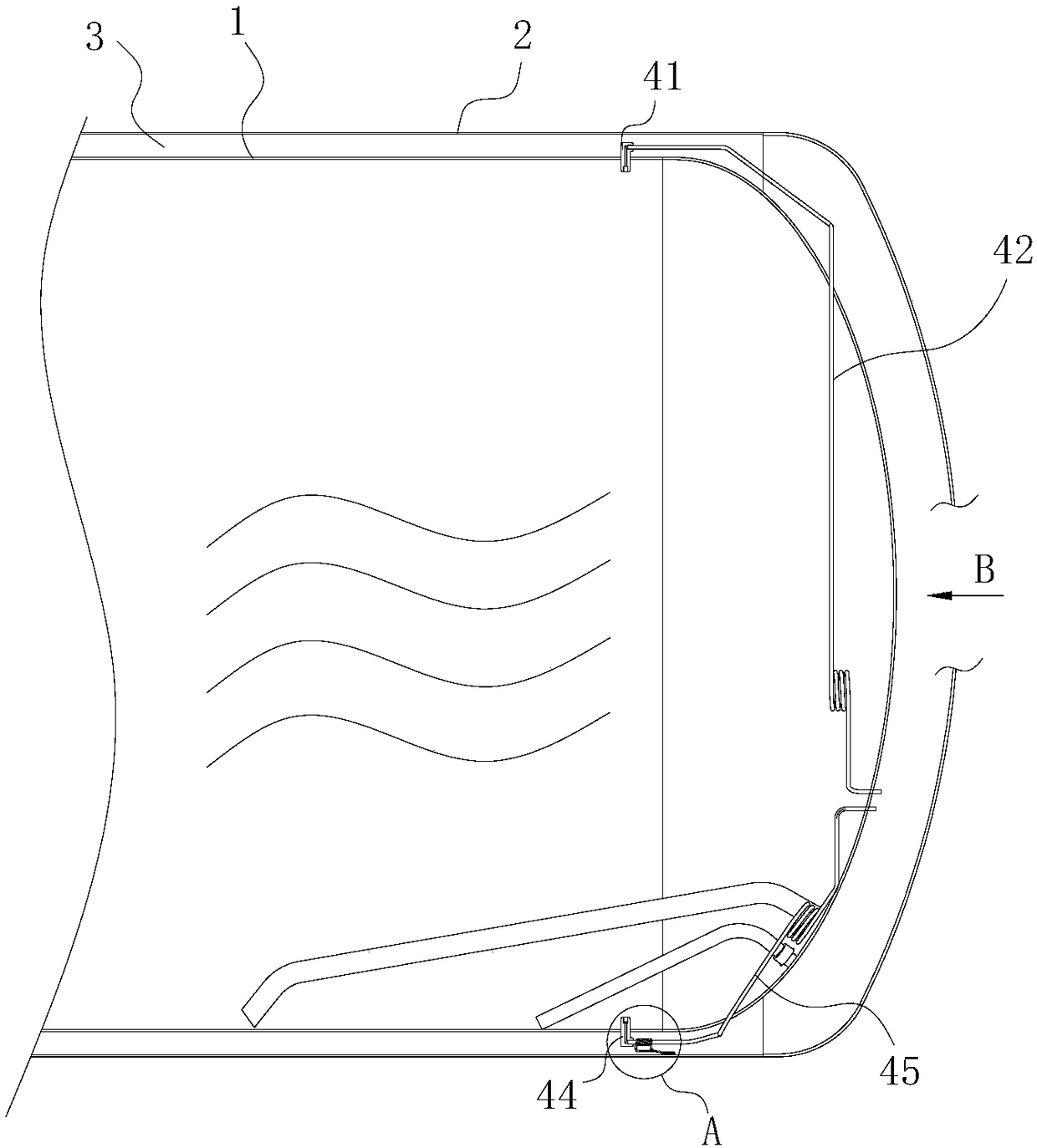

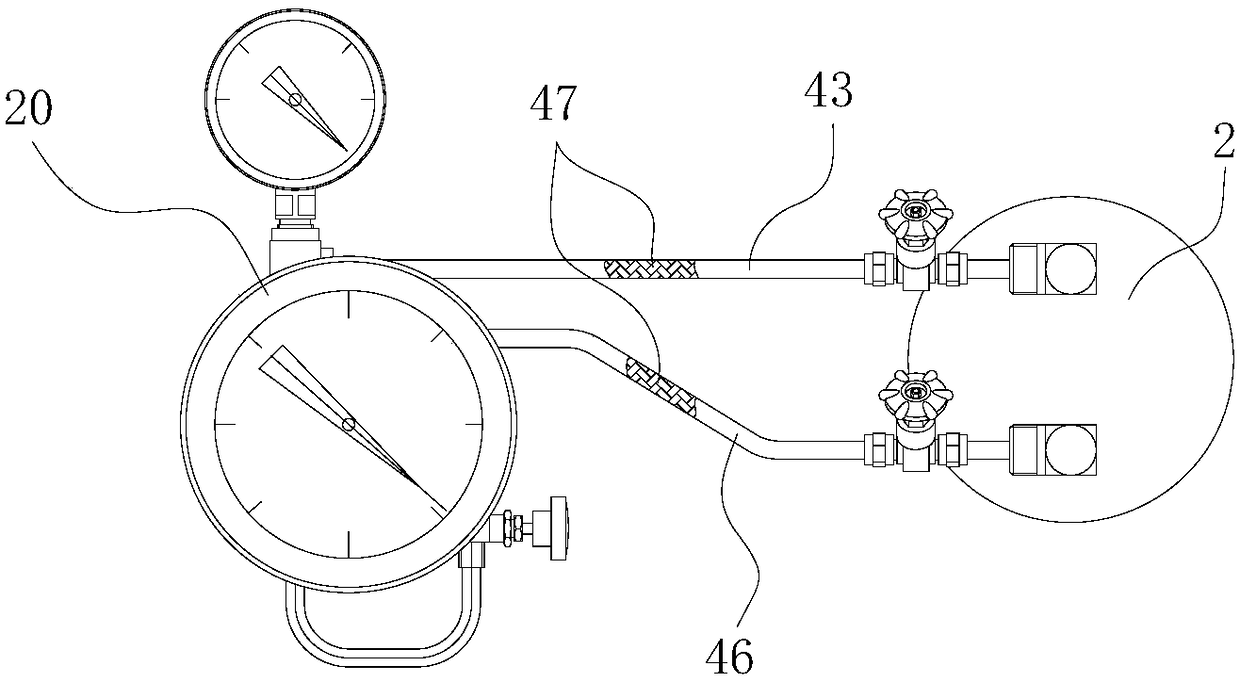

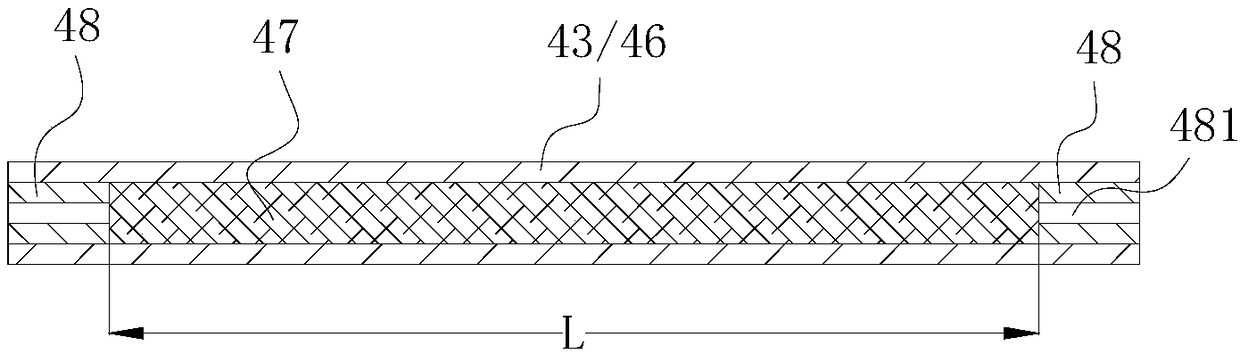

[0026] The invention provides a pressure-taking device for measuring the liquid level of a low-temperature container and a low-temperature container with the pressure-taking device. The liquid level of the low-temperature container is measured by a differential pressure liquid level gauge. The pressure-taking device has a gas phase pipeline and The liquid phase pipeline is used to respectively lead the gas and liquid phase pressure of the cryogenic container to the differential pressure level gauge.

[0027] Such as figure 1 As shown, the cryogenic conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com