External loading test bench of stand column and jack

A technology of test bench and jack, which is applied in the field of column jacks, can solve the problems of high processing precision, complex assembly, high cost, etc., and achieve the effect of reducing work content, improving test efficiency, and improving test accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

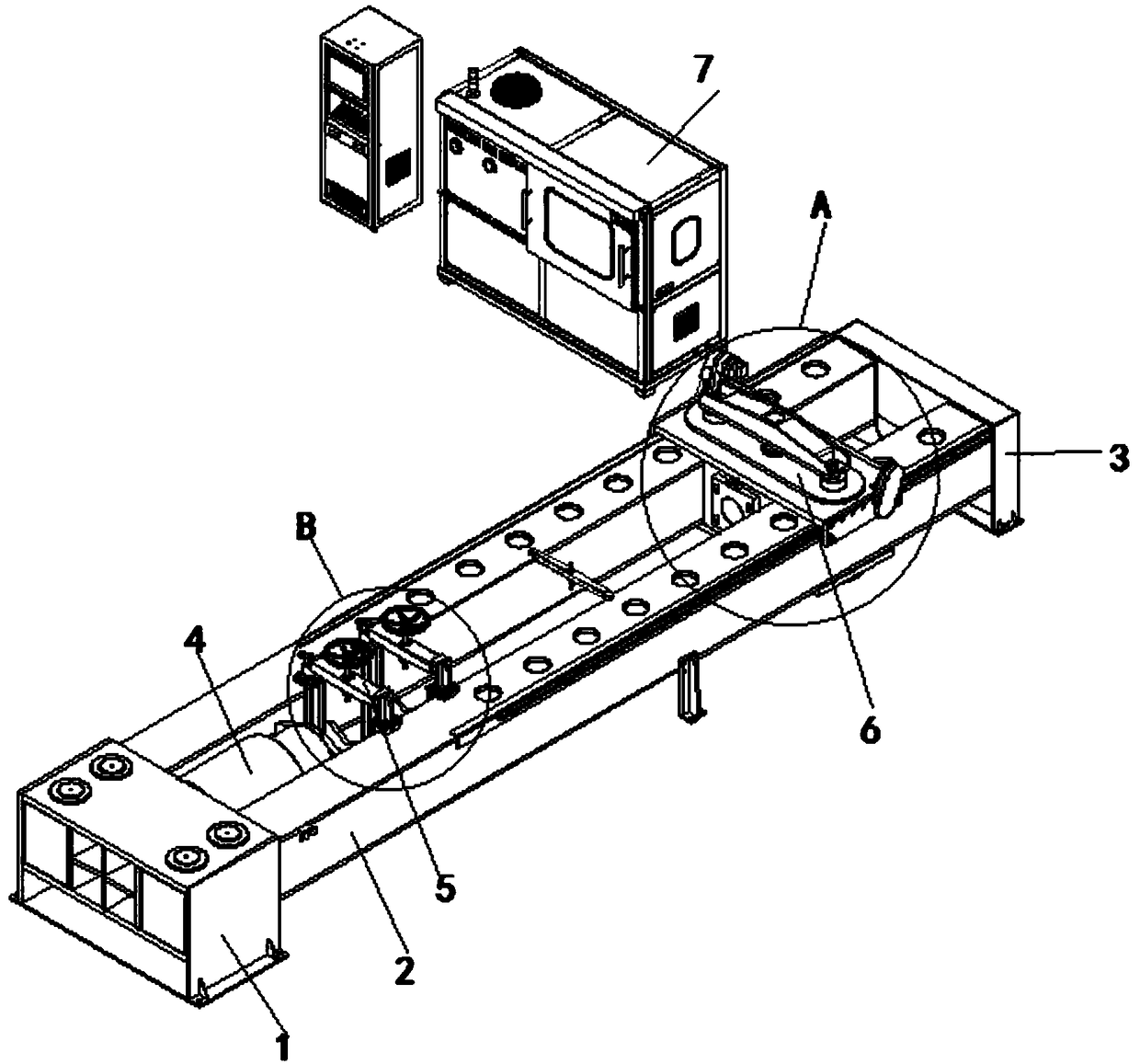

[0017] A kind of column jack external loading test bench, such as figure 1 As shown, it includes a terminal base 1 and two opposite columns 2 vertically installed and fixed on the two ends of the side wall of the terminal base 1. One end of the two columns 2 is connected and fixed through a connecting plate 3; A loading oil cylinder 4 is vertically fixed, and the loading oil cylinder 4 is located between two columns 2. Two clamping mechanisms 5 are clamped and installed between one ends of the two columns 2, and a sliding mechanism is installed between the other ends of the two columns 2. Movable beam 6, the bottom end of the column jack to be tested is installed and fixed on the movable beam 6, and the top is installed and connected with the power end of the loading cylinder 4;

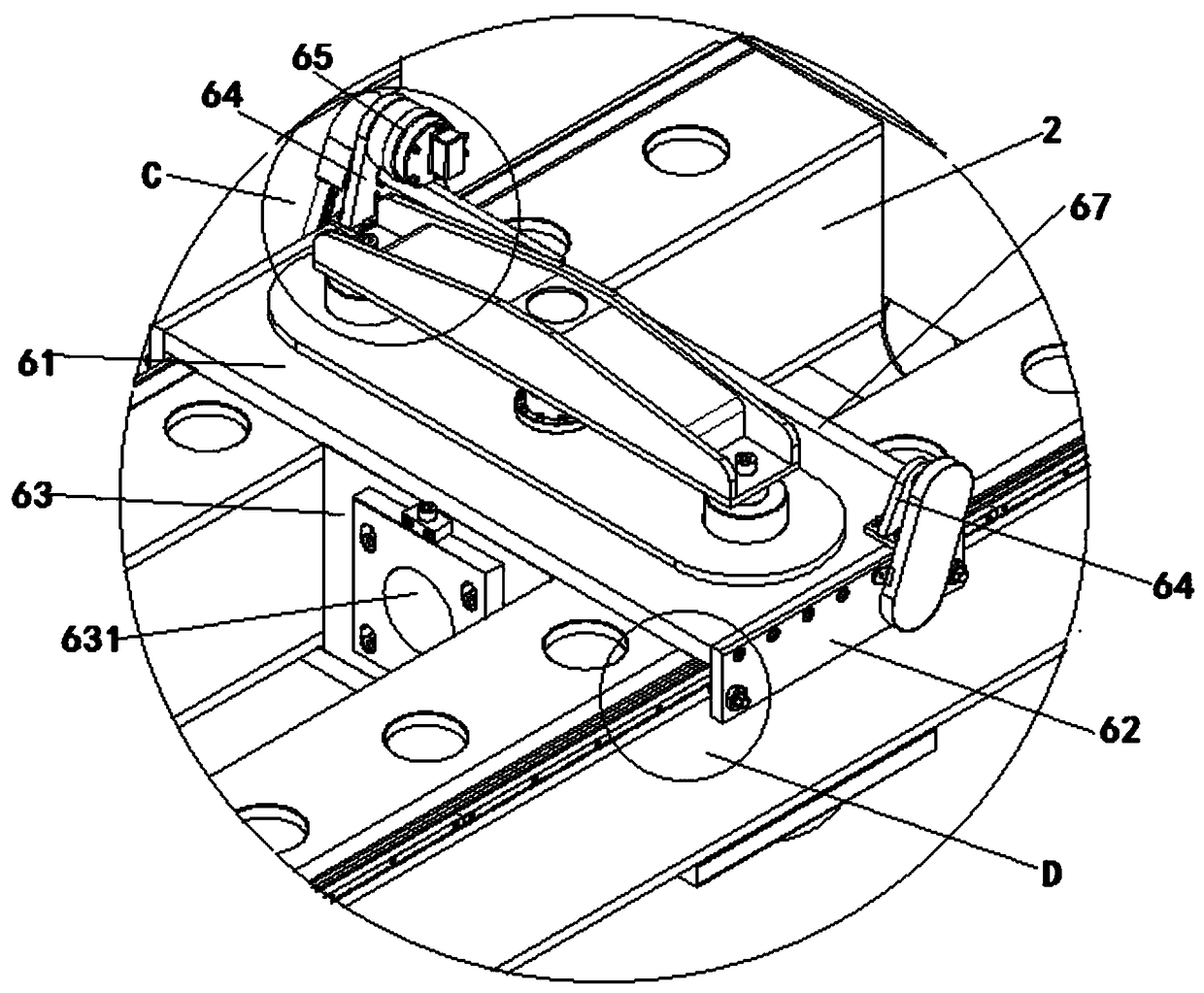

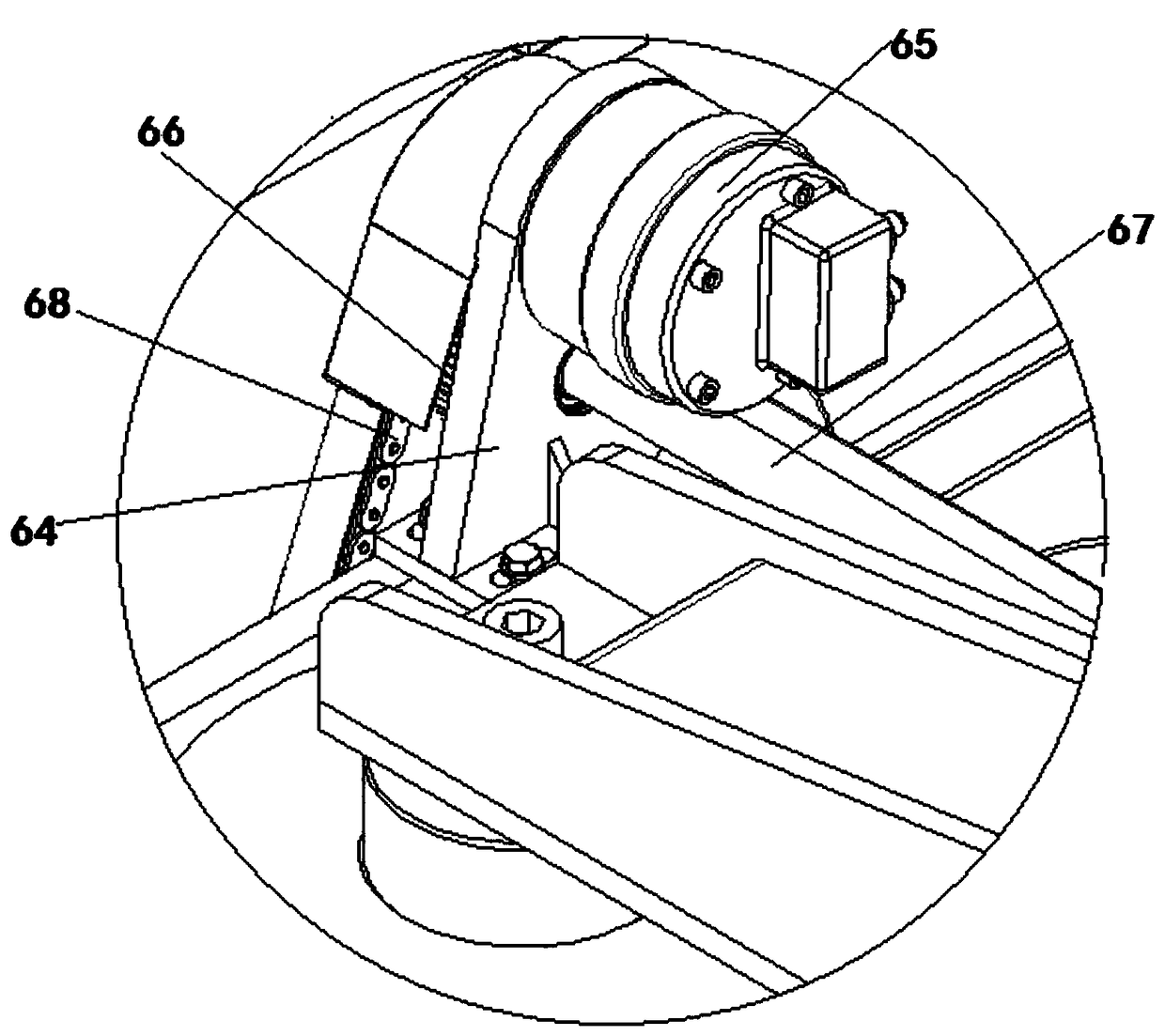

[0018] like figure 2 , image 3 and Figure 4 As shown, the outer surfaces of the top side walls of the two columns 2 are fixed with racks 21, and the movable beam 6 includes a support fixed plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com