Concrete slump test board

A technology of slump and test bench, applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve problems affecting the judgment of concrete quality, affecting the quality of concrete pouring, and different test results, so as to ensure the quality of pouring and conception Novel, consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with embodiment.

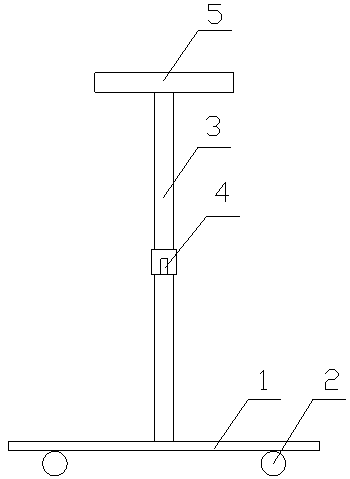

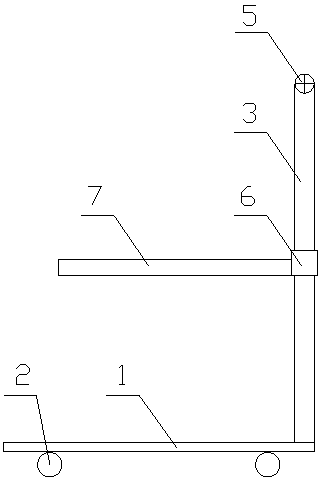

[0014] Depend on figure 1 , 2 It can be seen that the concrete slump test bench is composed of a platform plate 1, a measuring pole 3 and a scale 4. The platform plate 1 is square and adopts a steel plate with a thickness of 8mm. ; Vertically set a measuring pole with a scale on the platform plate, the measuring pole is cylindrical, welded on the center of one side of the edge of the platform plate, and the scale is marked on the pole for reading the height of the concrete; the measuring pole The top welding handle 5 is used for the movement of the concrete slump test bench; the set ruler scale on the measuring pole is composed of a sleeve 6 and a beam 7, and the inner diameter of the sleeve is slightly larger than the diameter of the measuring pole, which is convenient for the scale to move up and down; the beam It is horizontally welded on the sleeve, and is on the same plane as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com