IGBT device current waveform test board

A technology of current waveform and test board, which is applied in the field of test board structure, can solve problems such as inflexibility, high cost, and limited test range, and achieve the effects of improving measurement quality, solving influence, and reducing production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] In an embodiment, the current discharge waveform of the CDM model detects a double-sided test board structure.

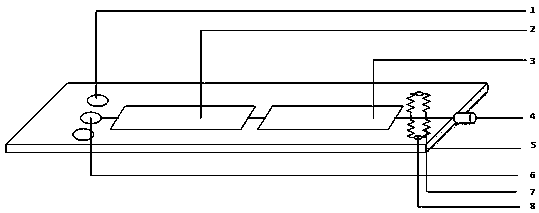

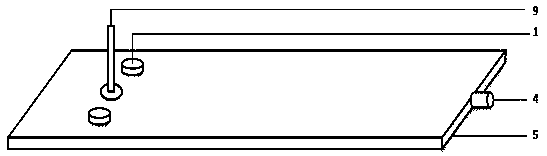

[0036] figure 1 and figure 2 The top and bottom views of the double-sided test board structure in the first embodiment of the present invention are respectively. Combining with this figure, it can be seen that the double-sided test board structure of this embodiment includes: a through-hole structure 1 with a fixing function on the back, which is used to install screws or other fixed devices; filter 2 for filtering out high-frequency interference; attenuator 3 for reducing current peaks to facilitate testing; grounding plate connected to metal socket 4 to connect the oscilloscope and test board through a coaxial cable; For connecting the grounding plate 5 of all parts, each module is assembled and has a grounding effect, and can be connected with other parts of the test system; pogo (pogo stick) probe 6, the part on the back of the test board is the probe b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com