tft array substrate and method of making the same

A technology of an array substrate and a manufacturing method, which is applied in the field of TFT array substrate and its manufacturing, can solve the problems of excessive chromaticity difference between the center position and the edge position of blue sub-pixels, affecting product color, etc., so as to increase the photoresist and reduce the Loss, the effect of reducing chromaticity differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Please refer to the drawings in the accompanying drawings, wherein like reference numerals refer to like components. The following description is based on illustrated specific embodiments of the invention, which should not be construed as limiting other specific embodiments of the invention not described in detail herein.

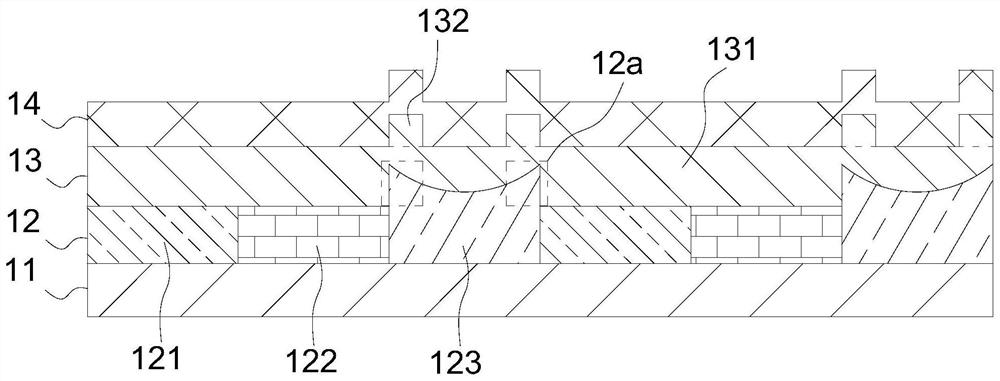

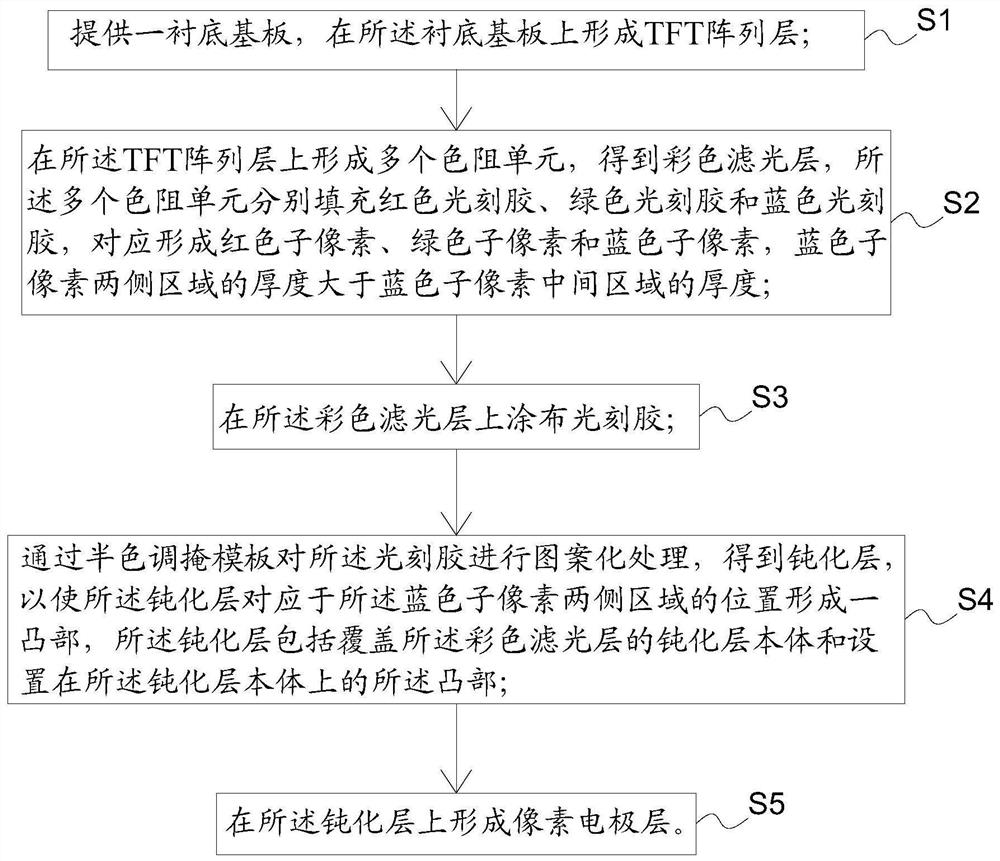

[0041] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a preferred embodiment of the TFT array substrate of the present invention.

[0042] The TFT array substrate of the preferred embodiment of the present invention includes a TFT array layer 11 , a color filter layer 12 , a passivation layer 13 and a pixel electrode layer 14 .

[0043] Specifically, the color filter layer 12 is disposed on the TFT array layer 11, and includes a plurality of color-resist units, the plurality of color-resist units are respectively filled with red photoresist, green photoresist and blue photoresist, and correspondingly form a red photores...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com