Protective film of conductive adhesive, circuit board and manufacturing method of display device

A manufacturing method and circuit board technology, applied in overvoltage protection, printed circuit manufacturing, printed circuit components, etc., can solve the problems of conductive adhesive failure, conductive adhesive protective film easy to fall off, etc., to increase adhesion and reduce tearing The effect of removing force and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

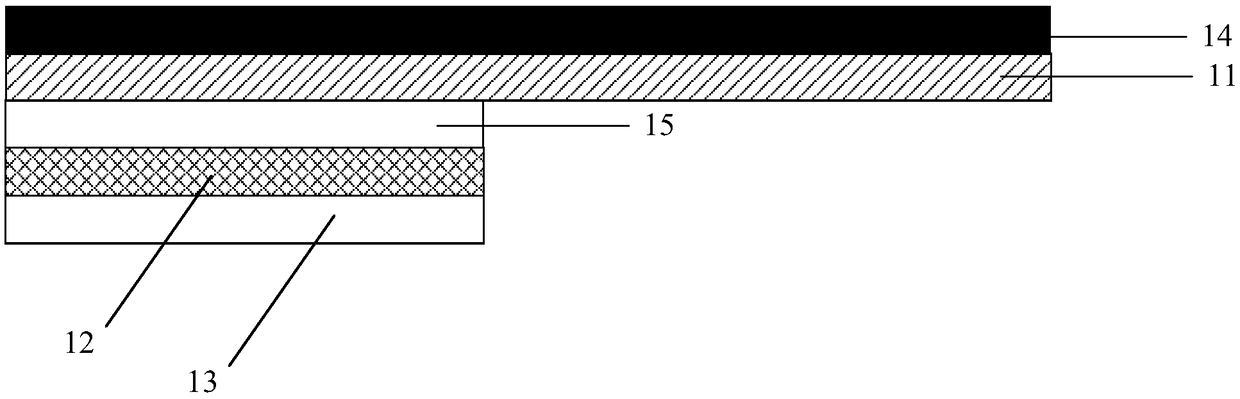

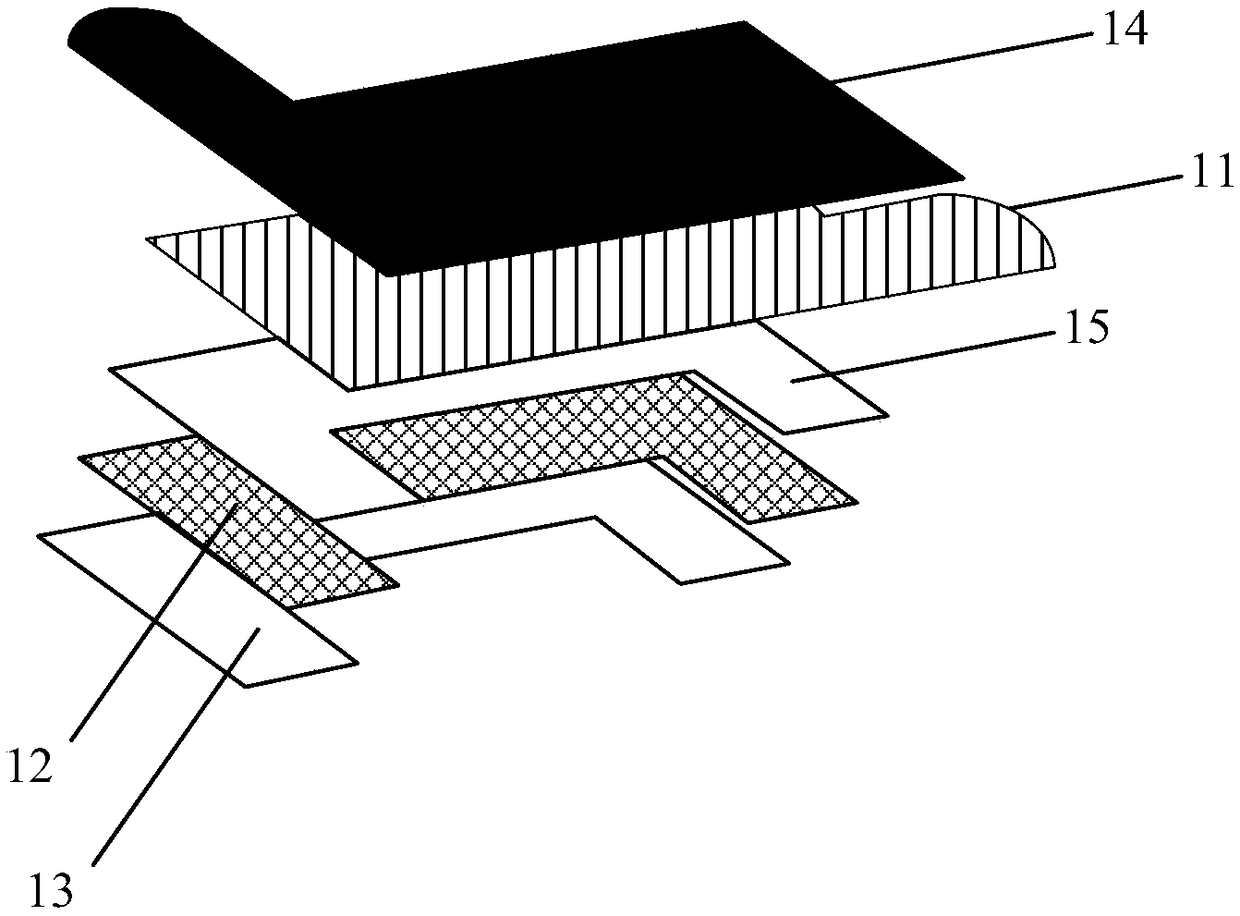

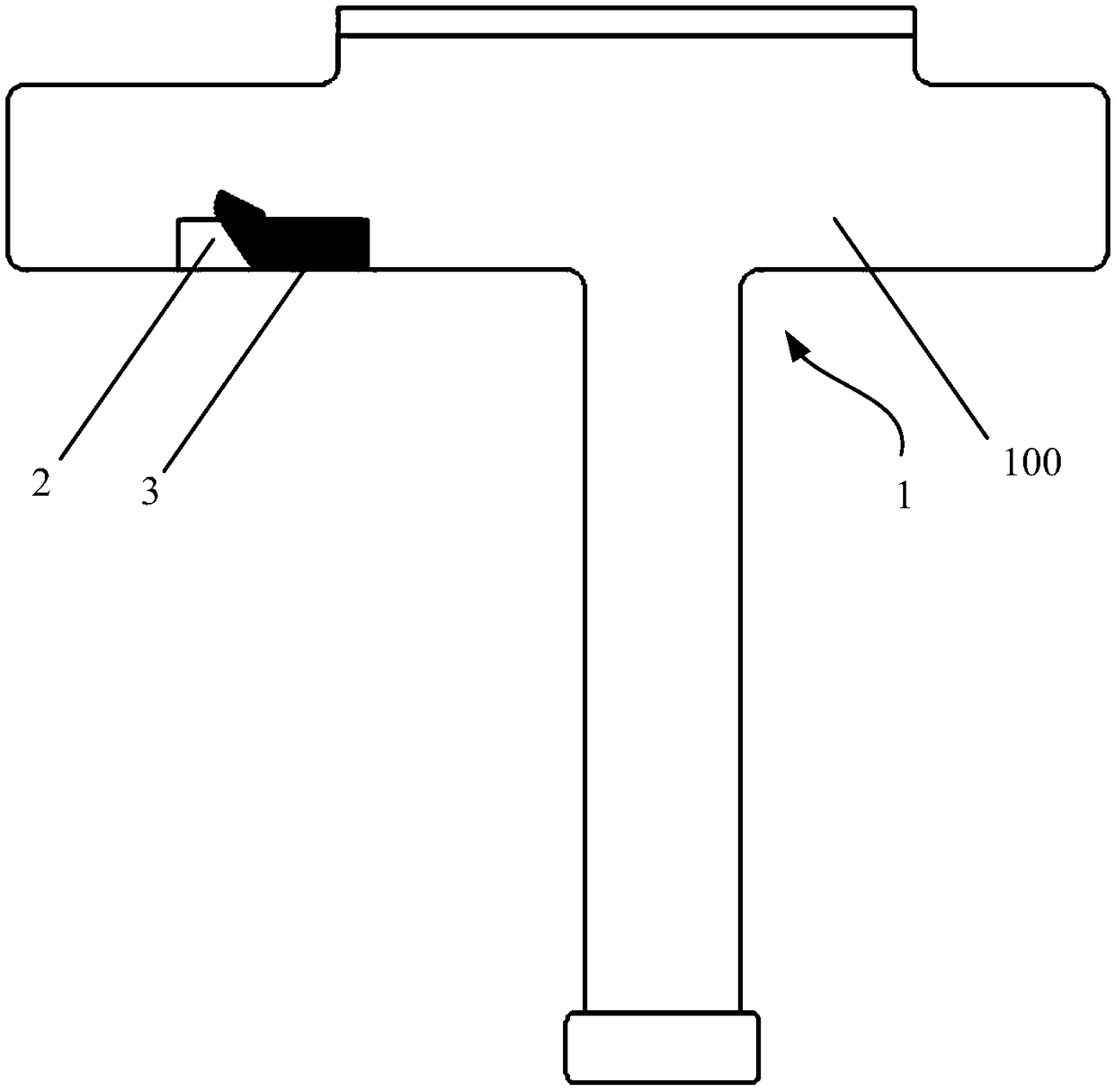

[0033] In the prior art, the exposed copper area is usually made on the circuit board to discharge static electricity, and the exposed copper area is electrically connected with the metal structure of the electronic device through conductive glue, so as to discharge the static electricity faster. Limited by the structure, the area of the exposed copper area is small. In order to prevent the conductive adhesive from being torn off at the same time when the protective film on the conductive adhesive is torn off, the adhesion between the conductive adhesive and the protective film is small, but it is easy to cause the protective film to be damaged during the production process. Falling off, causing the conductive adhesive to lose its viscosity and conductive properties.

[0034] In order to solve the above technical problems, the present invention provides a protective film of conductive adhesive and a circuit board. The protective film includes a substrate and a photoreleasabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com