A method for enhancing heat transfer performance of spray cooling

A technology of spray cooling and heat exchange performance, applied in chemical instruments and methods, cooling/ventilation/heating transformation, heat exchange materials, etc. , to achieve the effect of improving heat transfer coefficient, reducing surface temperature and saving working fluid

Active Publication Date: 2019-01-04

UNIV OF SHANGHAI FOR SCI & TECH

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing spray cooling technology, even if the surfactant SDS is introduced into the spray cooling system, still has defects such as low cooling efficiency, large consumption of working fluid, and poor surface temperature uniformity.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

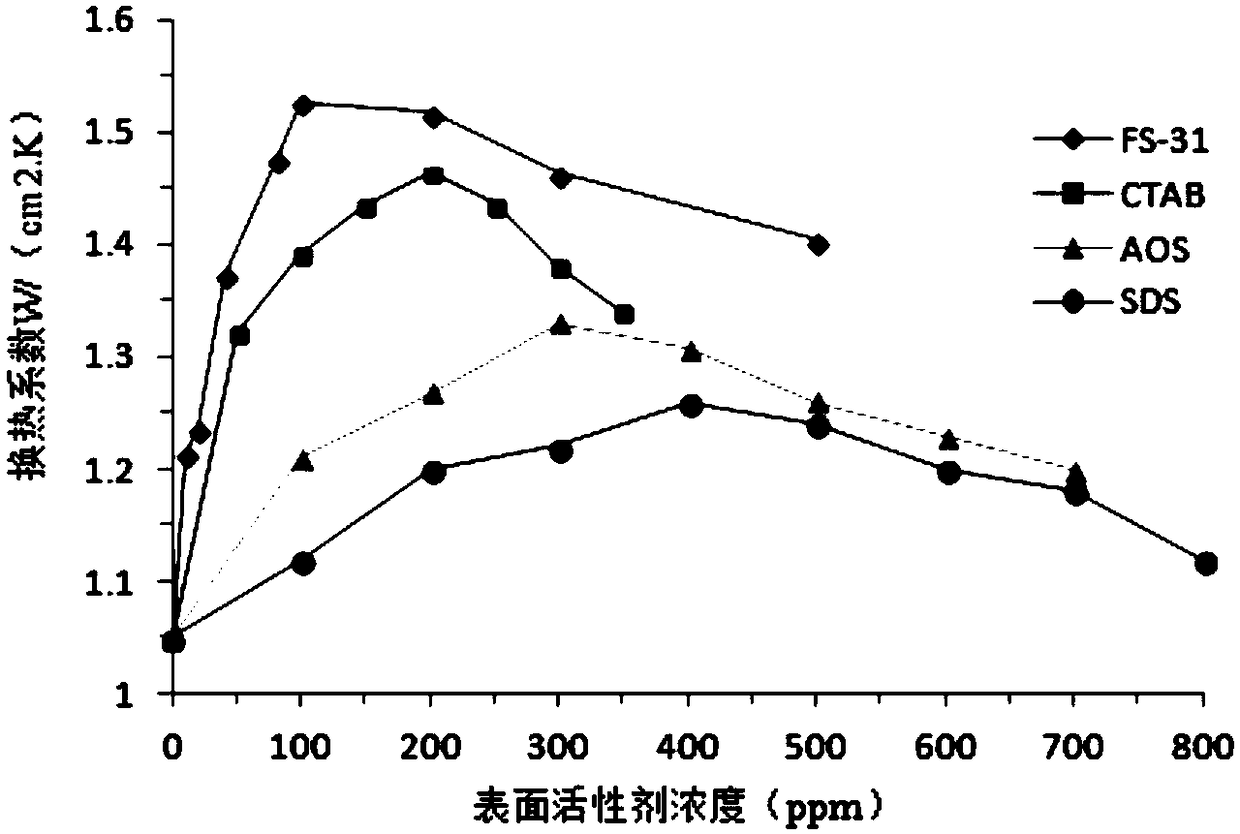

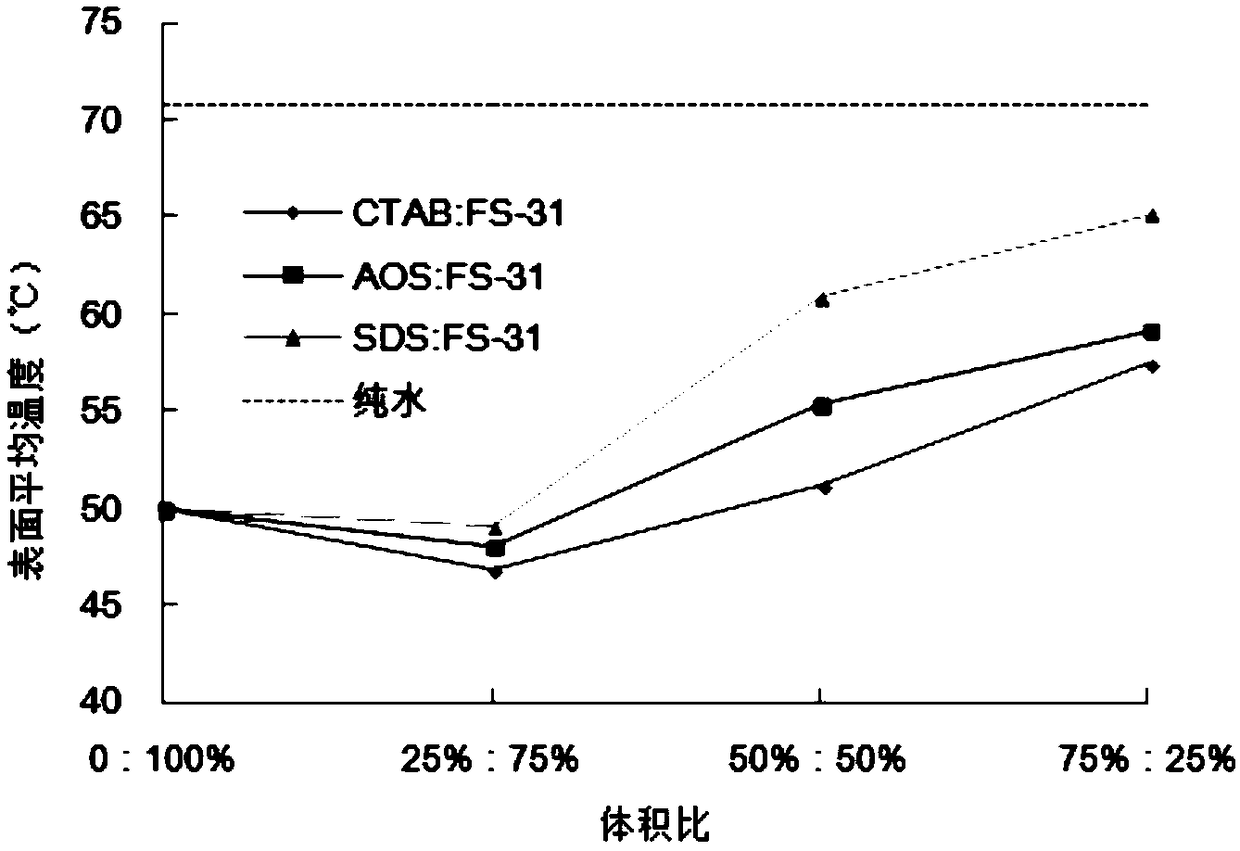

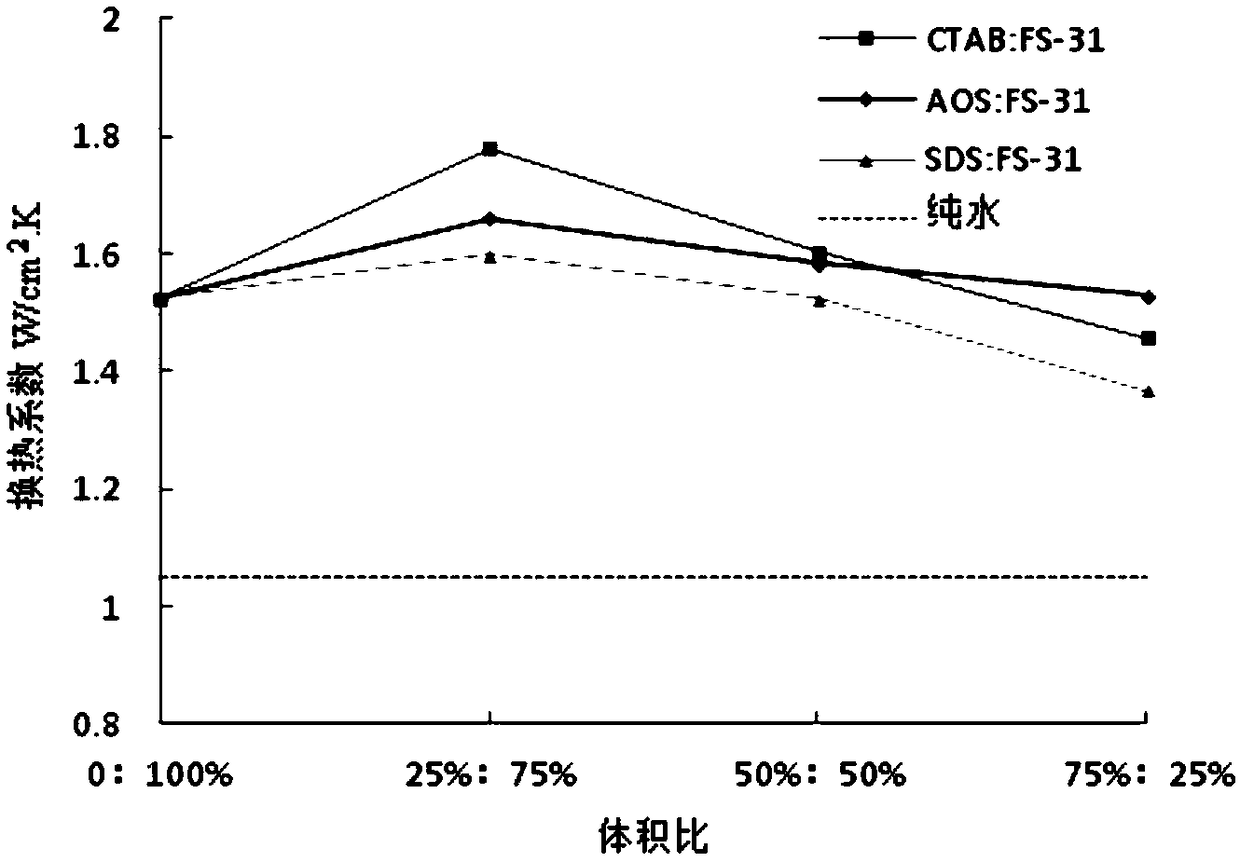

[0032] The present invention uses DuPont FS-31 tensio-active agent, and the spray cooling experiment that the combination of FS-31 and surfactants such as CTAB, AOS, SDS carries out respectively is as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for enhancing heat transfer performance of spray cooling. It includes: carrying out spray cooling by use of FS-31 aqueous solution with a concentration of 50-200ppm asa spray cooling medium; mixing the CTAB aqueous solution with the concentration of 200ppm with the FS-31 aqueous solution with the concentration of 100ppm according to the ratio of 0:100%-50%:50%, ormixing the AOS aqueous solution with the concentration of 300ppm with the FS-31 aqueous solution with the concentration of 100ppm according to the ratio of 0:100%-50%:50%, or mixing the SDS aqueous solution with the concentration of 400ppm with the FS-31 aqueous solution with the concentration of 100ppm according to the ratio of 0:100%-50%:50%; and using the prepared solution as a spray cooling working medium to carry out spray cooling. The method can improve the heat transfer performance of spray cooling, increase the heat transfer coefficient, reduce the surface temperature of heat source,save working medium, and meet the cooling requirements of electronic equipment with high heat flux density.

Description

technical field [0001] The invention belongs to the technical field of high heat flux spray cooling heat transfer and its application, and relates to a method for enhancing the performance of spray cooling heat transfer. Background technique [0002] As a new type of cooling technology, spray cooling can greatly improve the heat dissipation potential of electronic components, and has become one of the most concerned cooling methods in the field of high heat flux electronic cooling. In view of the fact that there are many influencing factors of spray cooling, the mechanism is also relatively complicated. In order to give full play to the application of spray cooling in practical engineering, research on spray cooling working fluid is currently being carried out. [0003] The spray cooling working fluid must not only meet the premise of heat dissipation, but also need to consider whether it is compatible with electronic components, whether it has an impact on the environment,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H05K7/20C09K5/10

CPCC09K5/10H05K7/20

Inventor 刘妮殷小明

Owner UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com