Plate-processing and dimension-detecting auxiliary equipment

A technology for size detection and auxiliary equipment, applied in workshop equipment, manufacturing tools, etc., can solve problems such as inability to measure, save time and resources, improve detection accuracy, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

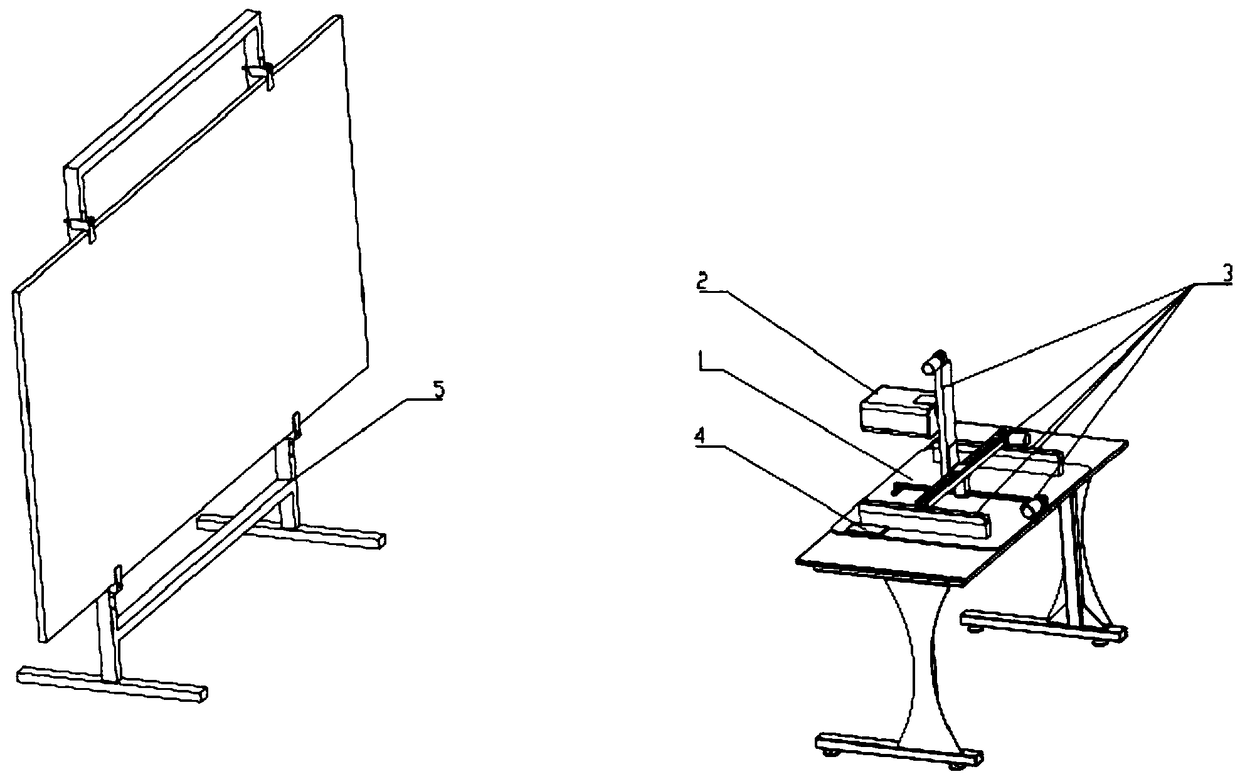

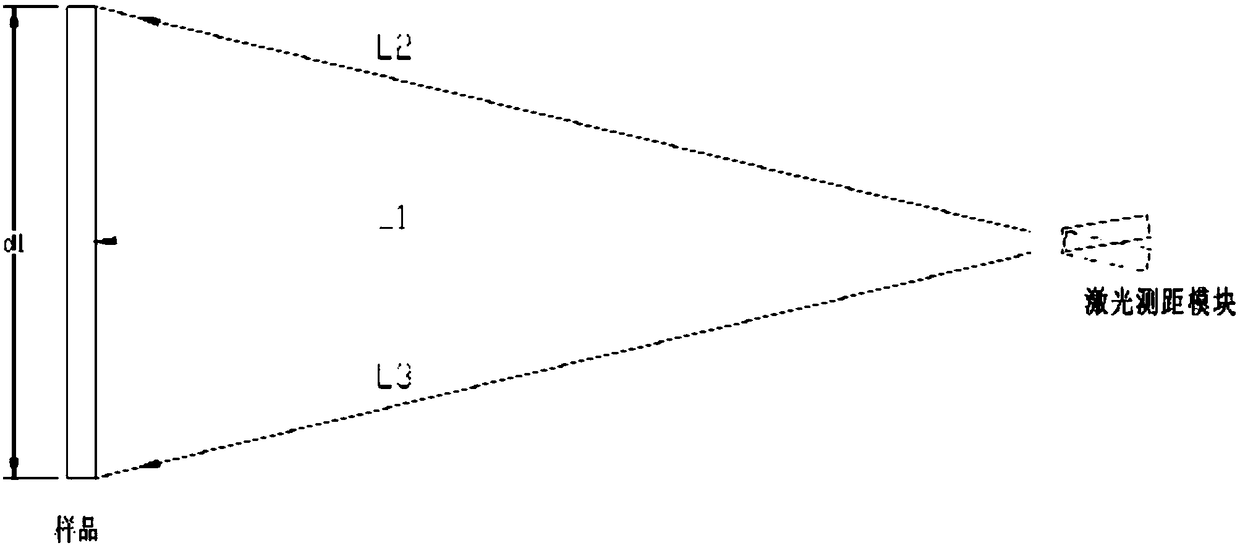

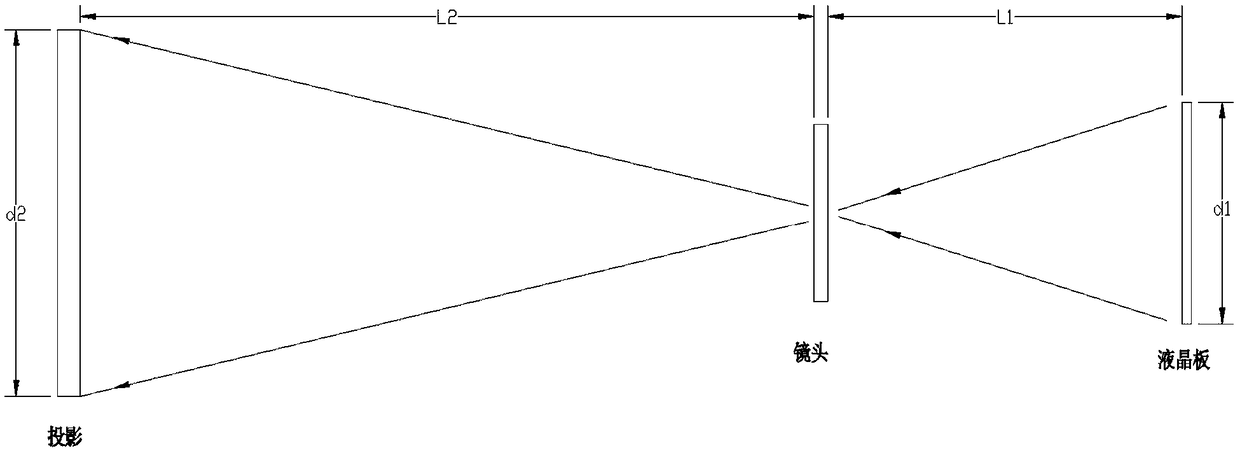

[0014] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as figure 1 As shown, in the plate processing and size detection auxiliary equipment provided by the embodiment of the present invention, it mainly includes five parts: a base plate 1, a projector 2, a three-axis gantry module 3, a controller 4, a sample and a fixed bracket 5, and the sample It is fixed on a fixed bracket and placed directly in front of the projection direction of the projector, which can be used to assist sample processing and size detection. For example, the sample is generally a rectangular or square plate, and the length and width of the sample are more than 1 meter. The length and width of the sample If it exceeds 1 meter, a tape measure or ruler will be used to measure the size and positioning during the conventional processing. The measurement tolerance of the tape measure or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com