An accurate brake fluid pressure regulating system for satisfying the pressurization requirement of wheel cylinder

A technology for regulating system and brake hydraulic pressure, applied in the direction of brake, brake transmission, transportation and packaging, etc., can solve the problem of immature control method, improve stability and safety, ensure reliability, and simple system structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

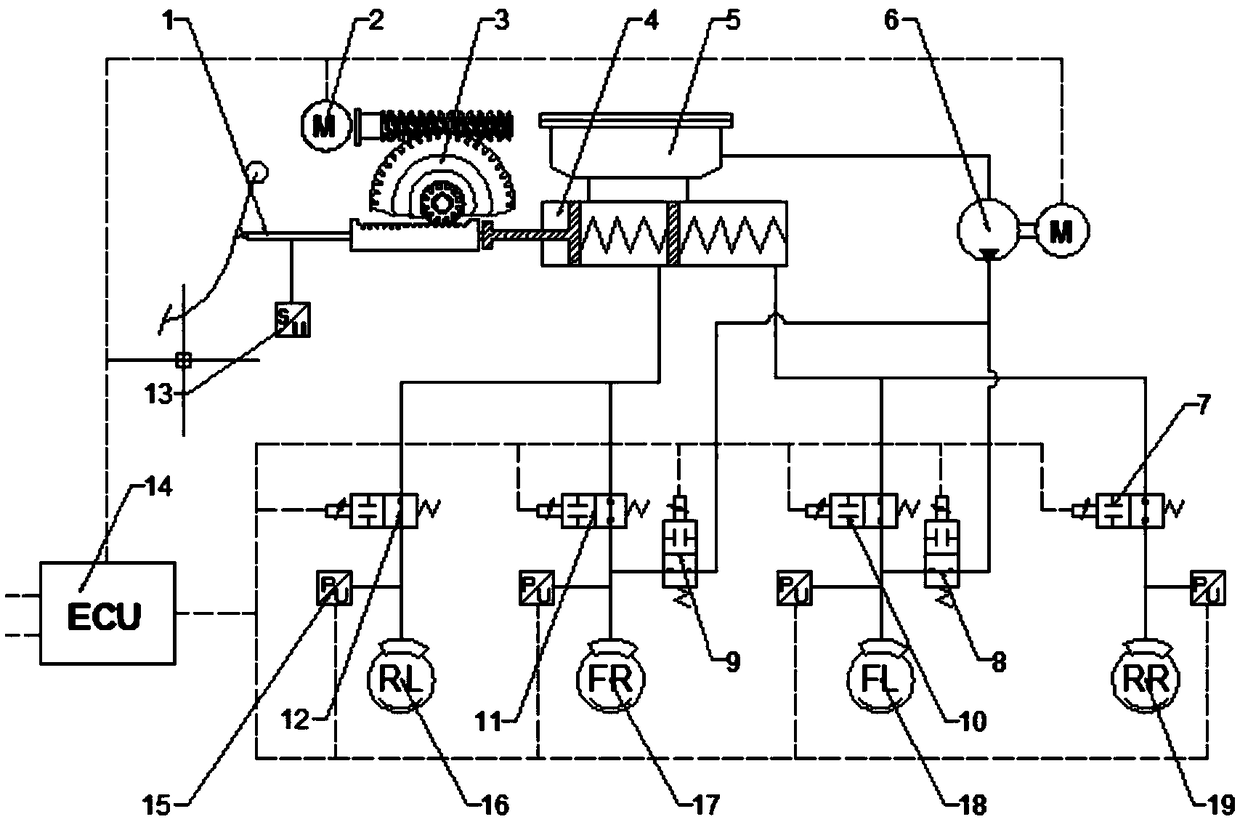

[0026] Such as figure 1 As shown, a brake fluid pressure precise adjustment system that meets the demand for wheel cylinder boosting is used to adjust the brake fluid pressure of the two front wheel cylinders and the two rear wheel cylinders of the vehicle. The system includes an electronic control unit 14 And the brake hydraulic pressure source, brake fluid pressure unit, auxiliary booster source, auxiliary booster unit and hydraulic pressure detection unit respectively connected thereto, the hydraulic pressure detection unit is connected to the front wheel cylinder and the rear wheel cylinder, and the brake hydraulic pressure The force unit is set with four lines. The four-way brake fluid pressure unit connects the front wheel cylinder and the rear wheel cylinder with the brake hydraulic pressure source respectively. The auxiliary booster unit is set with two or four lines. When two lines are set, the two lines The auxiliary supercharging unit connects the two front wheel cy...

Embodiment 2

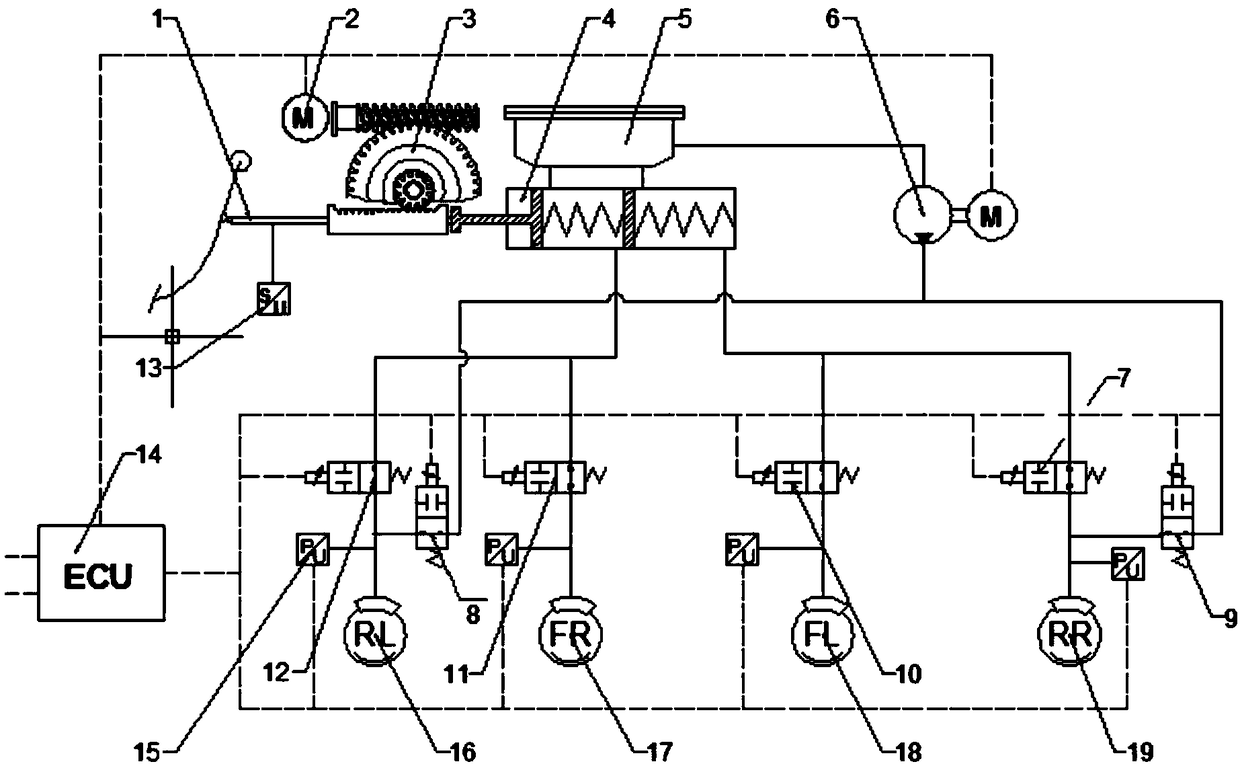

[0043] Such as figure 2 As shown, in this embodiment, the auxiliary booster unit of the brake fluid pressure precision adjustment system that meets the boosting requirements of the wheel cylinders is provided with two circuits and is respectively connected to two rear wheel cylinders, that is, the left rear wheel cylinder 18 and the right rear wheel cylinder 18. Wheel cylinder 19, other are all identical with embodiment 1.

[0044] In this embodiment, the specific working principle of the brake fluid pressure precise adjustment system that meets the demand of wheel cylinder boosting is as follows:

[0045] (1) Conventional braking conditions

[0046] When the electronic control unit 14 receives the normal braking command, the normally open solenoid valves 10 and 11 are in a power-off state, and the front wheel cylinders communicate with the brake master cylinder 4 . The normally open solenoid valves 7 and 12 are energized, and the rear wheel cylinders are disconnected from ...

Embodiment 3

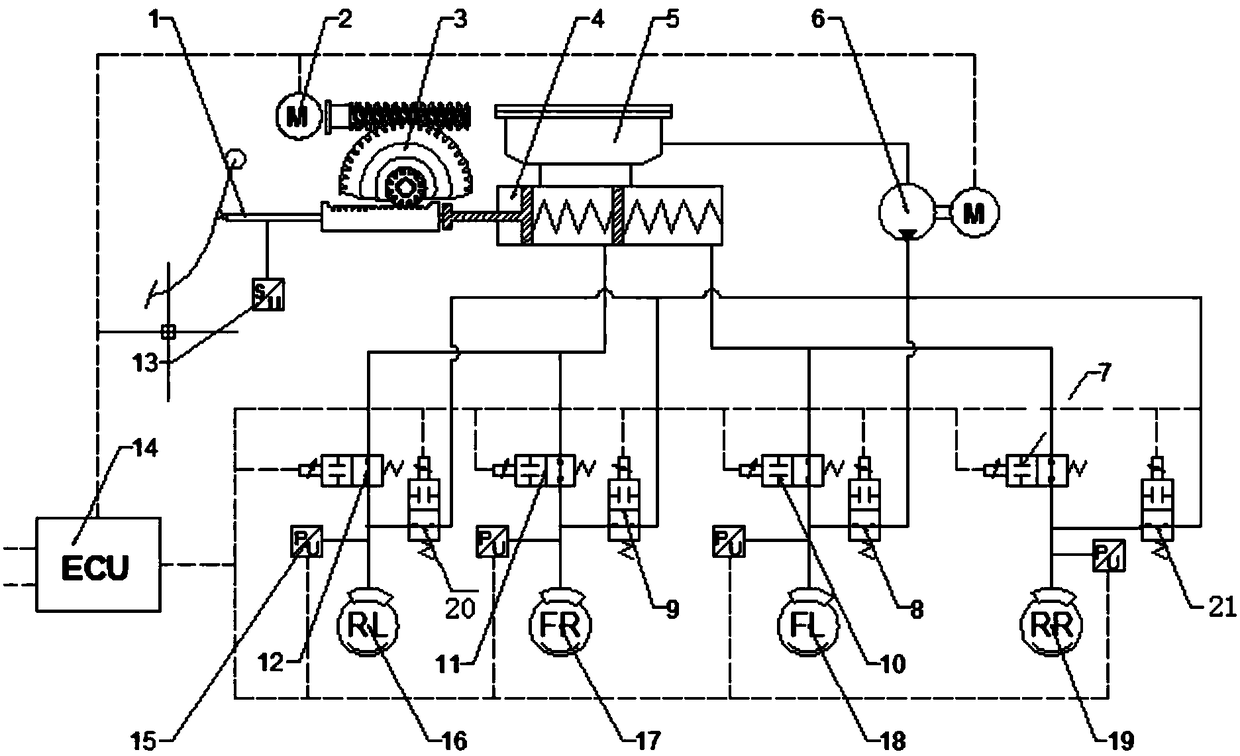

[0056] Such as image 3 As shown, in this embodiment, the brake fluid pressure precision adjustment system that meets the demand for wheel cylinder boosting is equipped with four auxiliary booster units, and the four auxiliary booster units respectively connect the front wheel cylinder and the rear wheel cylinder with the auxiliary booster Pressure source connection, all the other are the same as embodiment 1.

[0057] In this embodiment, the specific working principle of the brake fluid pressure precise adjustment system that meets the demand of wheel cylinder supercharging is similar to that of Embodiment 1 and Embodiment 2. Since the front wheel cylinder and the rear wheel cylinder are equipped with two sets of supercharging One set is a boosting and reducing mechanism consisting of a brake hydraulic source and a brake fluid pressure unit, and the other is an auxiliary boosting mechanism consisting of an auxiliary boosting source and an auxiliary boosting unit. During the c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap