Medical pill quantitative bottling device

A technology for bottling and pilling, which is applied in the field of medical pill quantitative bottling devices, which can solve the problems of arm pain and low efficiency of pill quantitative bottling, and achieve the effects of preventing arm pain, improving bottling efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

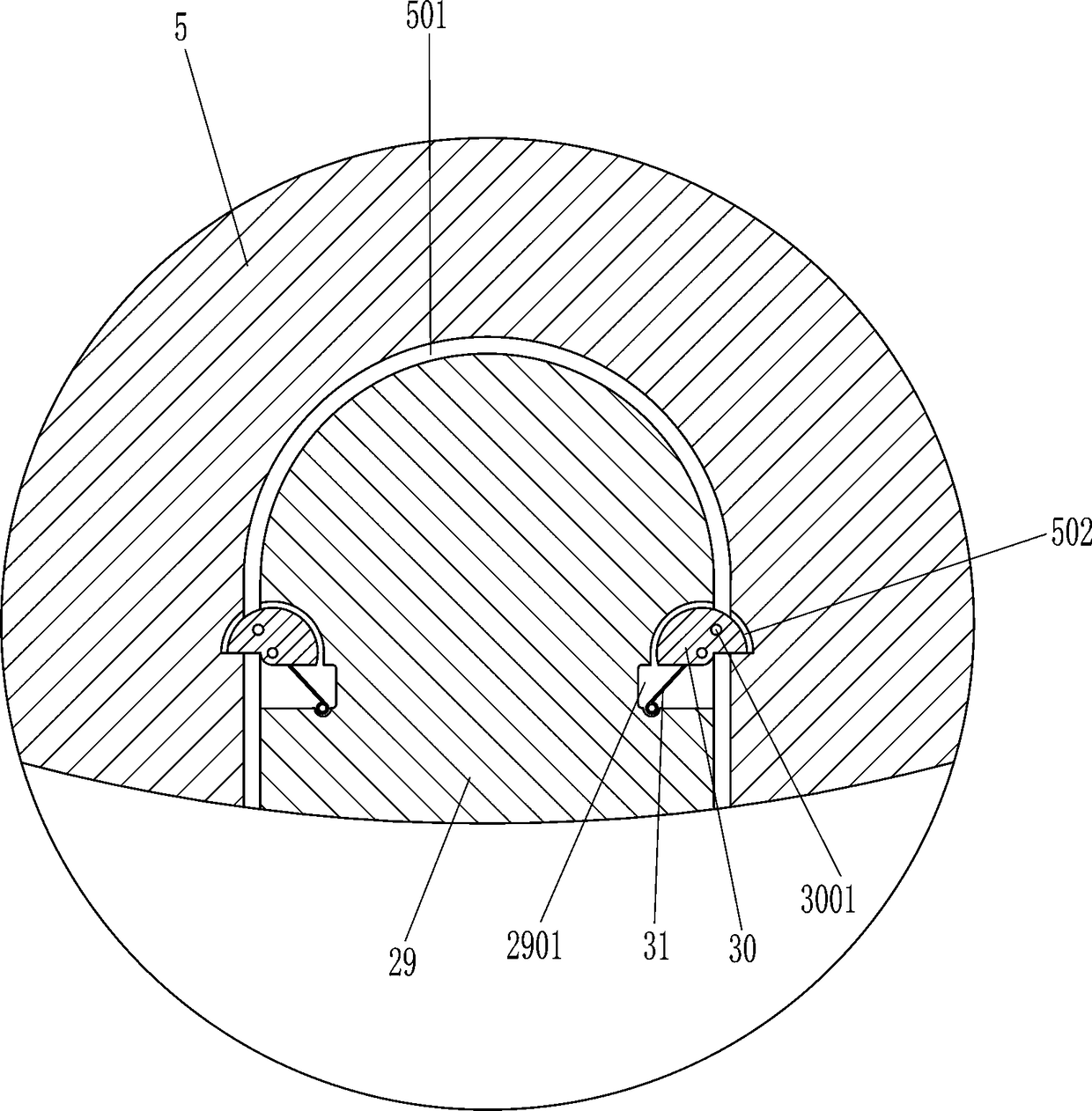

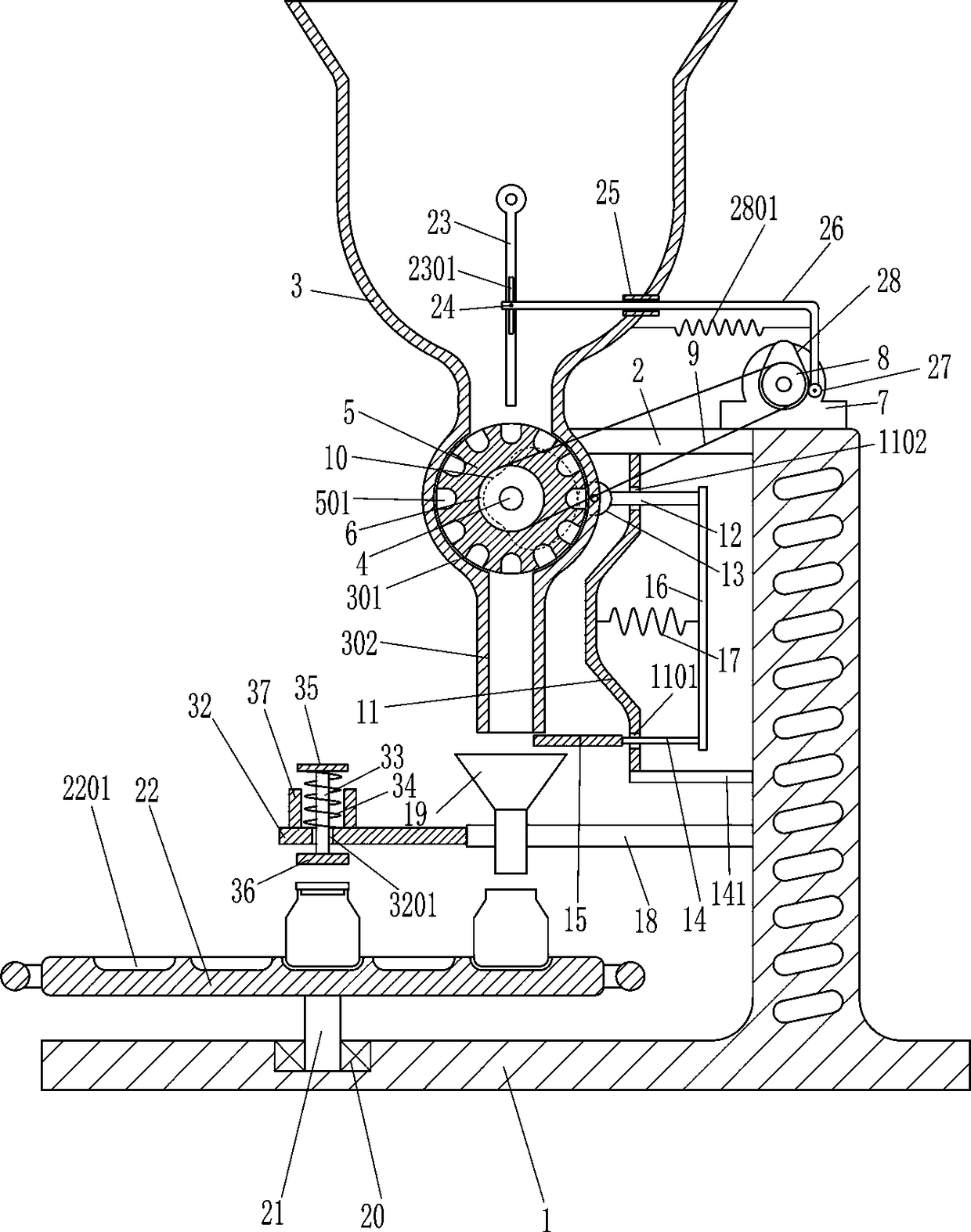

[0020] A quantitative bottling device for medical pills, such as Figure 1-2As shown, it includes a frame 1, a first support 2, a medicine barrel 3, a barrel neck 301, a barrel pipe 302, a first rotating shaft 4, a grooved plate 5, a first pulley 6, a motor 7, a second pulley 8, Belt 9, blanking cam 10, second support 11, first guide rod 12, first roller 13, second guide rod 14, fixed rod 141, baffle plate 15, connecting rod 16, first extension spring 17, third Support 18 and medicine bucket 19, the first support 2 is installed on the left side of the top of the frame 1, the medicine barrel 3 is fixed on the left side of the first support 2, the barrel neck 301 is fixed on the bottom of the medicine barrel 3, and the barrel pipe 302 is arranged on At the bottom of the barrel neck 301, the first rotating shaft 4 is rotatably installed on the rear side of the barrel neck 301. The first rotating shaft 4 is fixed with a grooved disc 5 which plays a role in conveying. Groove 501, ...

Embodiment 2

[0022] A quantitative bottling device for medical pills, such as Figure 1-2 As shown, it includes a frame 1, a first support 2, a medicine barrel 3, a barrel neck 301, a barrel pipe 302, a first rotating shaft 4, a grooved plate 5, a first pulley 6, a motor 7, a second pulley 8, Belt 9, blanking cam 10, second support 11, first guide rod 12, first roller 13, second guide rod 14, fixed rod 141, baffle plate 15, connecting rod 16, first extension spring 17, third Support 18 and medicine bucket 19, the first support 2 is installed on the left side of the top of the frame 1, the medicine barrel 3 is fixed on the left side of the first support 2, the barrel neck 301 is fixed on the bottom of the medicine barrel 3, and the barrel pipe 302 is arranged on At the bottom of the barrel neck 301, the first rotating shaft 4 is rotatably installed on the rear side of the barrel neck 301. The first rotating shaft 4 is fixed with a grooved disc 5 which plays a role in conveying. Groove 501,...

Embodiment 3

[0025] A quantitative bottling device for medical pills, such as Figure 1-2 As shown, it includes a frame 1, a first support 2, a medicine barrel 3, a barrel neck 301, a barrel pipe 302, a first rotating shaft 4, a grooved plate 5, a first pulley 6, a motor 7, a second pulley 8, Belt 9, blanking cam 10, second support 11, first guide rod 12, first roller 13, second guide rod 14, fixed rod 141, baffle plate 15, connecting rod 16, first extension spring 17, third Support 18 and medicine bucket 19, the first support 2 is installed on the left side of the top of the frame 1, the medicine barrel 3 is fixed on the left side of the first support 2, the barrel neck 301 is fixed on the bottom of the medicine barrel 3, and the barrel pipe 302 is arranged on At the bottom of the barrel neck 301, the first rotating shaft 4 is rotatably installed on the rear side of the barrel neck 301. The first rotating shaft 4 is fixed with a grooved disc 5 which plays a role in conveying. Groove 501,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com