Wine barrel

A technology of wine barrels and wine outlets, which is applied in the field of wine barrels, can solve the problems of wine barrels that are not easy to place, break, and poor stability, and achieve the goal of preventing vibration from being transmitted to the wine storage cavity, reasonable design, and avoiding impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

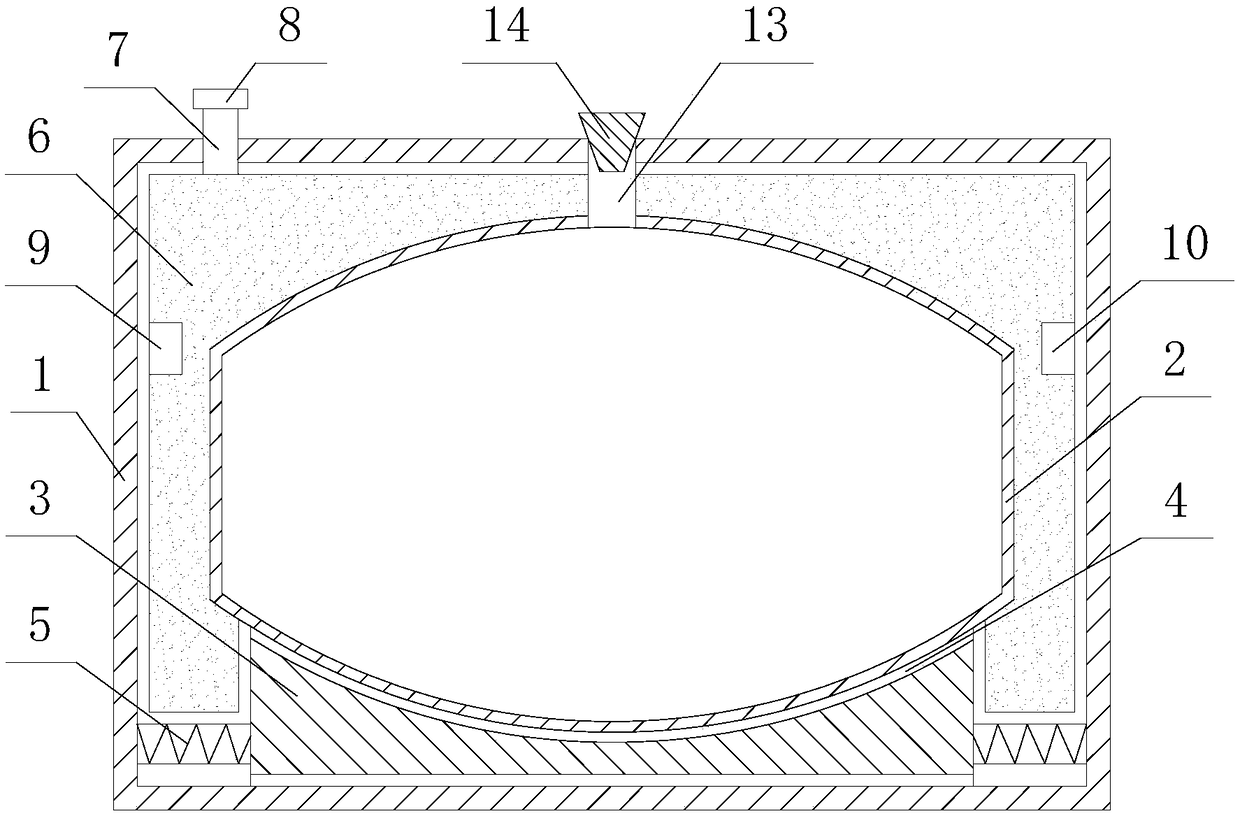

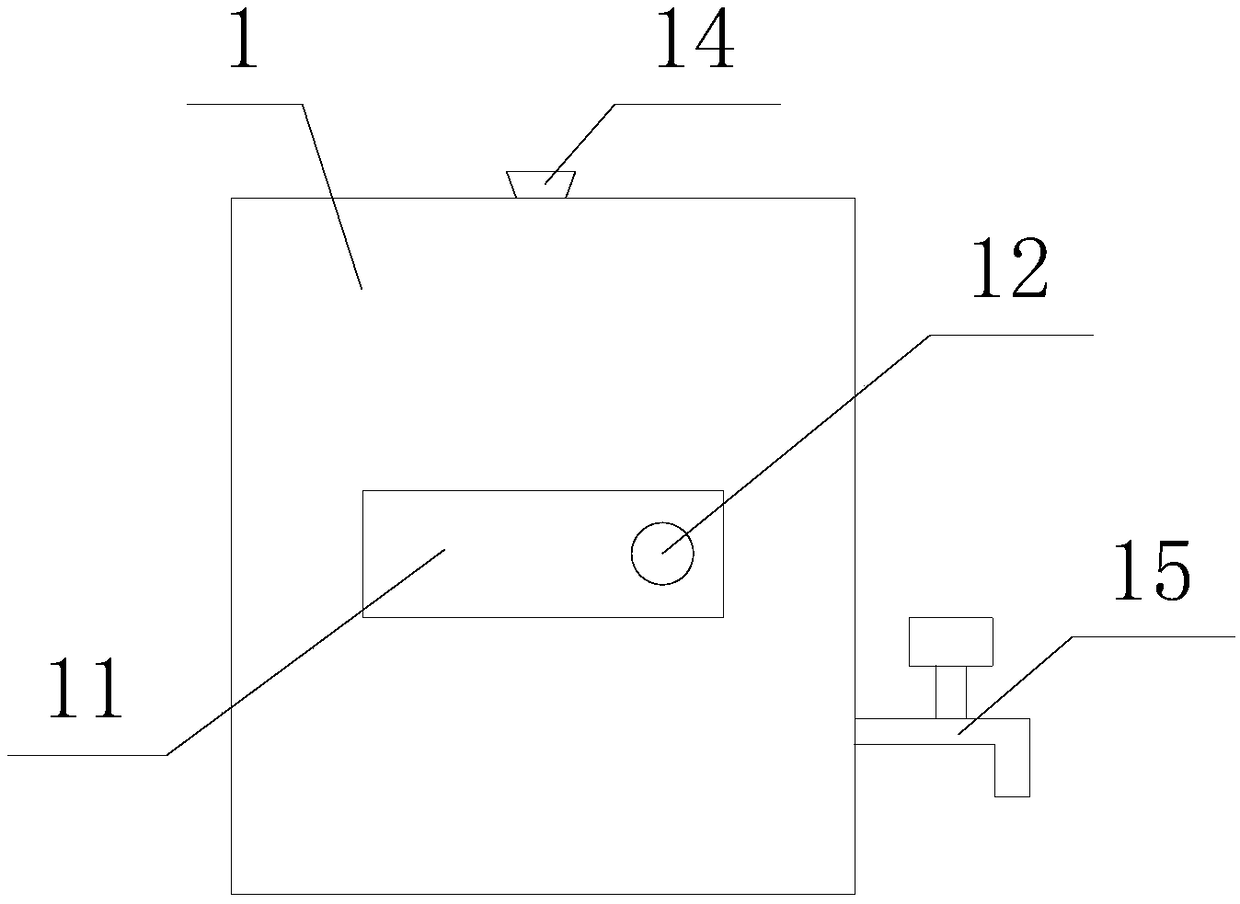

[0016] Such as figure 1 with figure 2 As shown, the wine barrel provided in this embodiment includes a stainless steel outer barrel 1 and a ceramic inner barrel 2. The stainless steel outer barrel 1 is a hollow cuboid inside. There is a placement groove 4 matching the ceramic inner barrel 2, and several evenly distributed shock-absorbing springs 5 are arranged between the outer walls around the rubber shock-absorbing seat 3 and the inner wall of the stainless steel outer barrel 1, and the ceramic inner barrel 2 is placed in the placement groove. In 4, a constant temperature regulating water jacket 6 is provided between the outer wall around the ceramic inner barrel 2 and the inner wall around the stainless steel outer barrel 1, and the constant temperature regulating water jacket 6 fills the gap between the outer wall of the ceramic inner barrel 2 and the inner wall of the stainless steel outer barrel 1. The top of one side of the regulating water jacket 6 is provided with...

Embodiment 2

[0021] It is basically the same as the above-mentioned embodiment 1, except that the ceramic inner barrel 2 is changed. The ceramic inner barrel 2 is in the shape of a waist drum placed horizontally, and the inner two ends of the ceramic inner barrel 2 are respectively fixedly connected with snap rings, and the two snap rings are opposite to each other. There are card slots on the side of the card release ring, and the matching oak circular plate is seamlessly clamped in the card release ring. Several oak wood boards matching the inner wall of the ceramic inner barrel 2 are arranged between the two card release rings. The two oak boards The ends are clamped respectively in the clamping slots of the two clamping rings, and the adjacent oak boards are seamlessly connected.

[0022] The invention greatly reduces the vibration generated by the collision by setting the rubber damping seat 3 and the damping spring 5, thereby avoiding the vibration of the ceramic inner barrel 2 and en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com