Gummed tape cutting device capable of measuring length

A tape cutting and length measuring technology, which is applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of not being able to intuitively understand the length of tape used, the lack of measuring devices for tape cutters, and inconvenient use, etc., to achieve design Novelty, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

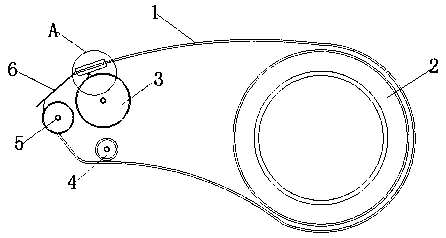

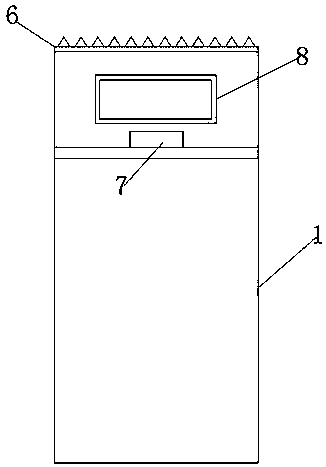

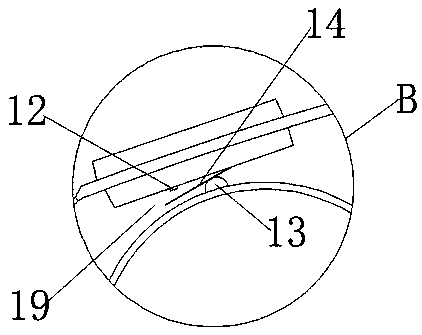

[0024] like figure 1 , figure 2 , image 3 and Image 6 As shown, the length-measurable tape cutter of the present invention includes a casing 1, one end of the casing 1 is fixedly connected with a fixed cylinder 2, and one end of the casing 1 away from the fixed cylinder 2 is rotatably connected with a guide wheel 5, and the guide wheel 5 A counting wheel 3 is arranged between the fixed cylinder 2, and the counting wheel 3 is rotationally connected with the casing 1. A cutting saw tooth 6 is arranged above the guide wheel 5, and a sleeve 4 is arranged below the counting wheel 3, and the sleeve 4 connects with the casing 1 through the rotating shaft. Fixed connection, the inner surface of the top of the shell 1 is fixedly connected with a counter 10, the counter 10 is located above the counting wheel 3, the counter 10 includes a circuit detection module 15, a signal processing module 16 and a single-chip microcomputer 17, one end of the upper surface of the shell 1 is fixed...

Embodiment 2

[0028] like figure 2 , Figure 4 , Figure 5 and Image 6 As shown, the length-measurable tape cutter of the present invention includes a casing 1, one end of the casing 1 is fixedly connected with a fixed cylinder 2, and one end of the casing 1 away from the fixed cylinder 2 is rotatably connected with a guide wheel 5, and the guide wheel 5 A counting wheel 3 is arranged between the fixed cylinder 2, and the counting wheel 3 is rotationally connected with the casing 1. A cutting saw tooth 6 is arranged above the guide wheel 5, and a sleeve 4 is arranged below the counting wheel 3, and the sleeve 4 connects with the casing 1 through the rotating shaft. Fixed connection, the inner surface of the top of the shell 1 is fixedly connected with a counter 10, the counter 10 is located above the counting wheel 3, the counter 10 includes a circuit detection module 15, a signal processing module 16 and a single-chip microcomputer 17, one end of the upper surface of the shell 1 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com