Manufacturing method of special cable used for wind power generation equipment

A technology for wind power generation equipment and special cables, which is used in the manufacture of cables/conductors, marking conductors/cables, insulating conductors/cables, etc., can solve problems such as reducing production costs, and achieve the advantages of low production difficulty, easy promotion, and avoidance of waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

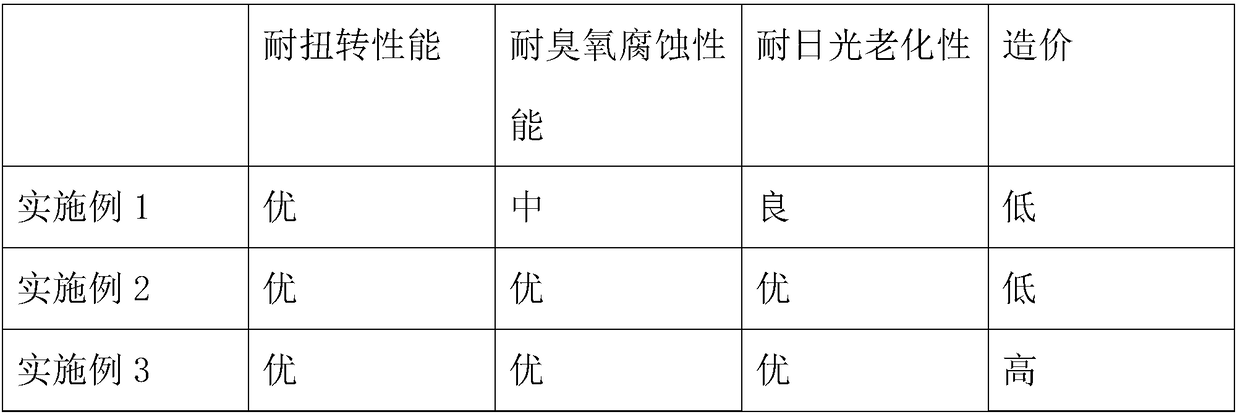

Embodiment 1

[0035] A method for manufacturing a special cable for wind power generation equipment, comprising the following steps:

[0036] Step 1. Cell drawing: After determining the product batch number, select the copper wire raw material, and draw the copper wire raw material through a drawing machine, and draw the copper wire raw material into a copper wire with a set diameter, which is used as a battery cell , and record the product batch number, material selection date, drawing date and cell set diameter;

[0037] Step 2. Coating of the inner insulating layer: Use an extruder to coat the inner insulating layer on the outside of the battery core described in step 1. The material of the inner insulating layer is set to ethylene propylene rubber, and the thickness of the inner insulating layer is set to 0.2mm. Record the material of the inner insulation layer, the thickness of the inner insulation layer and the coating date of the inner insulation layer;

[0038] Step 3, cell strandi...

Embodiment 2

[0050] A method for manufacturing a special cable for wind power generation equipment, comprising the following steps:

[0051] Step 1. Cell drawing: After determining the product batch number, select the copper wire raw material, and draw the copper wire raw material through a drawing machine, and draw the copper wire raw material into a copper wire with a set diameter, which is used as a battery cell , and record the product batch number, material selection date, drawing date and cell set diameter;

[0052] Step 2. Coating of the inner insulating layer: Use an extruder to coat the inner insulating layer on the outside of the battery core described in step 1. The material of the inner insulating layer is set to ethylene propylene rubber, and the thickness of the inner insulating layer is set to 0.3mm. Record the material of the inner insulation layer, the thickness of the inner insulation layer and the coating date of the inner insulation layer;

[0053] Step 3, cell stranding...

Embodiment 3

[0065] A method for manufacturing a special cable for wind power generation equipment, comprising the following steps:

[0066] Step 1. Cell drawing: After determining the product batch number, select the copper wire raw material, and draw the copper wire raw material through a drawing machine, and draw the copper wire raw material into a copper wire with a set diameter, which is used as a battery cell , and record the product batch number, material selection date, drawing date and cell set diameter;

[0067] Step 2. Coating of the inner insulating layer: Use an extruder to coat the inner insulating layer on the outside of the battery core described in Step 1. The material of the inner insulating layer is set to ethylene propylene rubber, and the thickness of the inner insulating layer is set to 0.4mm. Record the material of the inner insulation layer, the thickness of the inner insulation layer and the coating date of the inner insulation layer;

[0068] Step 3, cell strandi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com