Intelligent drift diameter gauge

A drift gauge and intelligent technology, which is applied in the directions of measurement, wellbore/well components, earthwork drilling and production, etc., can solve problems such as pipe stuck quality accidents, drift cannot be passed normally, and increase workover costs, etc., so as to improve construction efficiency , avoid falling objects stuck drill accidents, reduce the effect of risk quality accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

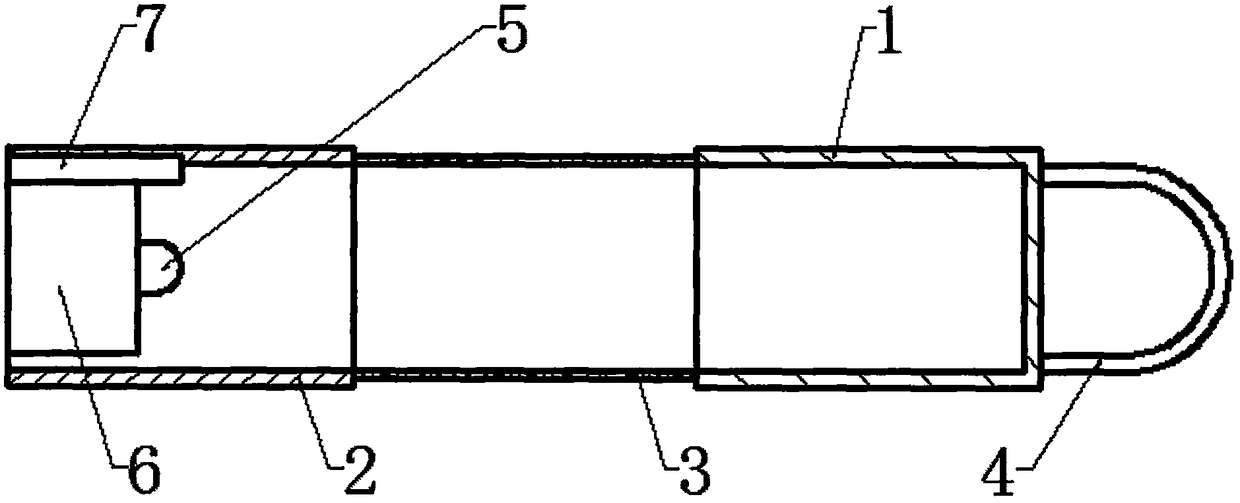

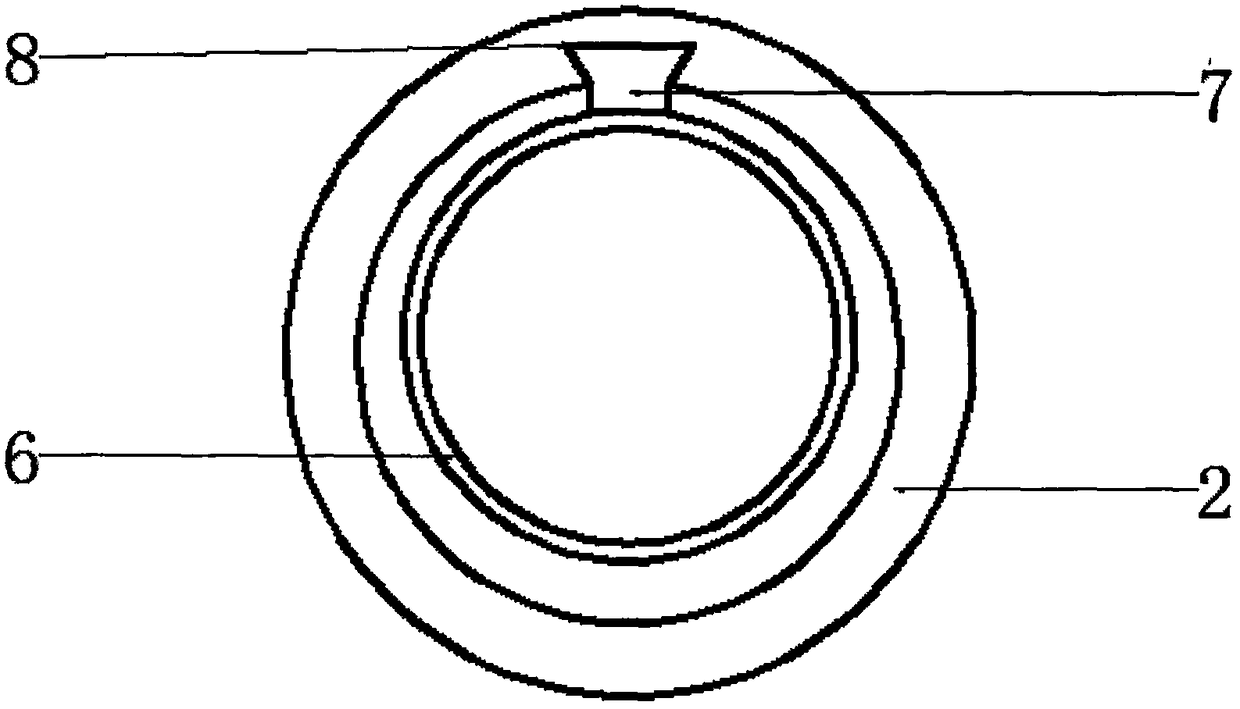

[0016] combine figure 1 and figure 2 , the intelligent diameter gauge includes a cylindrical body 1 with one end open, an upper joint 4 is provided at the closed end of the body 1, and a cylindrical guide head 2 with two open ends connected to the open end of the body 1 through a central tube 3, the guide head 2 There is a dovetail groove 8 on the inner wall, and a fixed block 7 is fixed in the dovetail groove 8. A cylindrical grit chamber 6 with one end open is arranged on the fixed block 7. The opening direction of the grit chamber 6 is in the same direction as the guide head 2. 6 Make the smart gauge itself have the function of a sedimentation cup to avoid the accident of falling objects stuck. The back side of the grit chamber 6 is equipped with an intelligent probe 5, which is used to detect the oil field downhole pipeline situation.

[0017] The main body 1, the guide head 2, and the upper joint 4 are all made of stainless steel, which is durable and has good corrosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com