Intelligent storage supervision equipment

A kind of equipment and storage technology, applied in the direction of material electrochemical variables, measuring devices, instruments, etc., can solve problems such as measurement errors, achieve the effects of controlling dosage, saving costs, and stabilizing storage conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

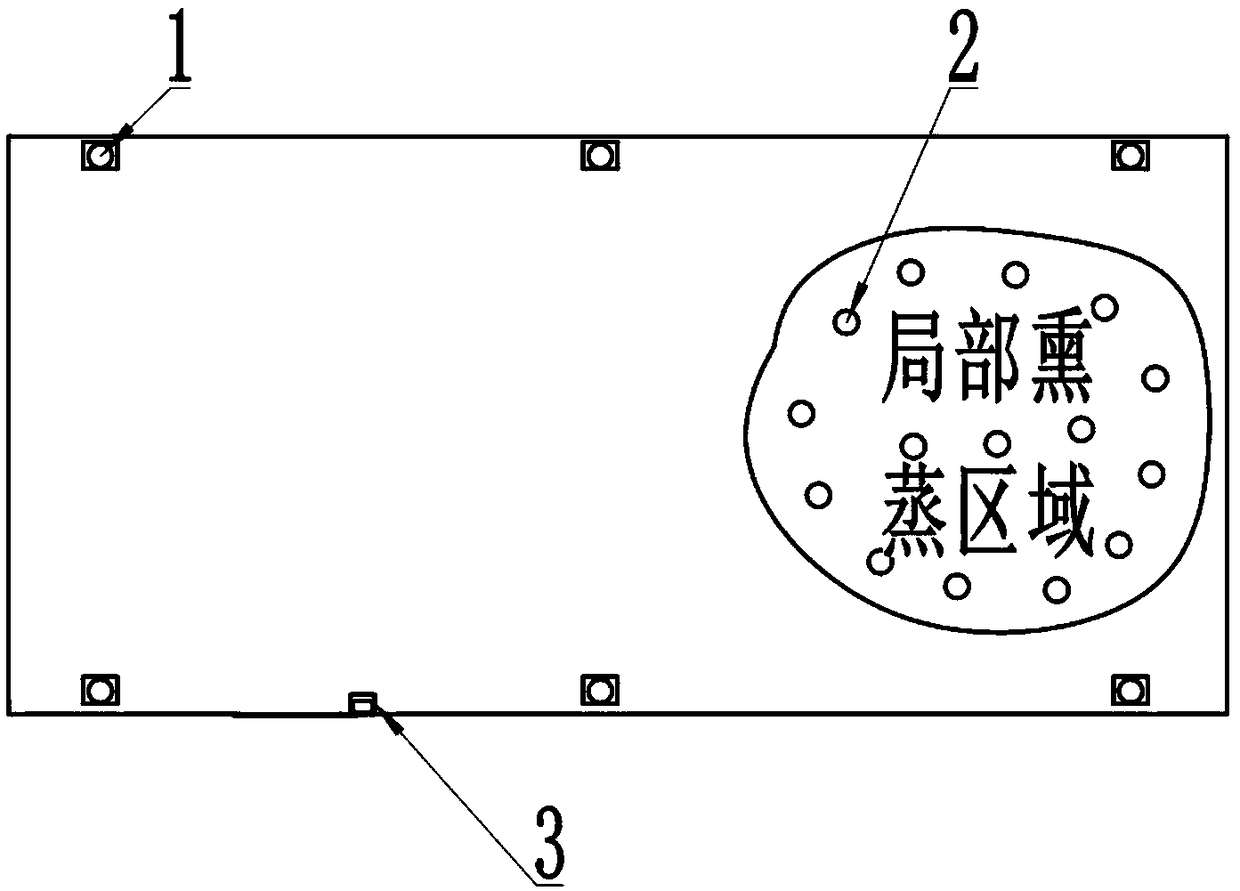

[0030] Partial fumigation of general grain warehouses to kill insects.

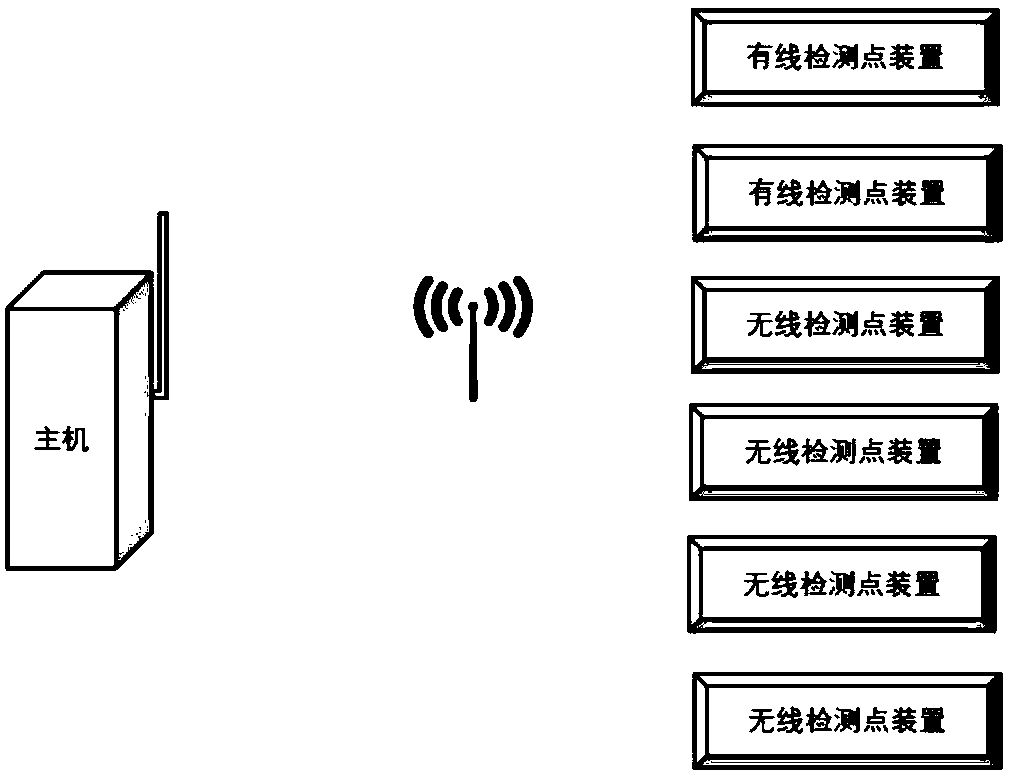

[0031] Such as Figure 1-3 As shown, a storage intelligent supervision device includes a detection point device and a host 3, and the detection point device includes a wired detection point device 1 powered by commercial power or solar energy and a wireless monitoring point device 2 powered by its own lithium battery , the lithium battery power of the wireless detection point device 2 can allow the device to work normally for 20 days, and the detection point device includes a three-in-one sensor and a wireless transmission module that can detect changes in the concentration of phosphine gas, temperature changes, and humidity changes in real time Composition, the wireless transmission module is a 433M wireless transmission module, the phosphine gas sensor is an electrochemical sensor, the wired detection point device 1 is fixed in the warehouse, and the working voltage of the wired detection point device 1...

Embodiment 2

[0037] Partial fumigation of large grain warehouses to kill insects.

[0038] It is the same as the first embodiment, but fumigation and insecticide are performed on two local areas at the same time, and the wireless detection point devices 2 are deployed to detect the two local areas, and the number of wireless detection point devices 2 is much more than that of the first embodiment.

[0039] The intelligent storage supervision equipment of the present invention adopts the fixed position detection of the wired detection point equipment and the wireless detection point equipment is set on the grain part that needs partial fumigation, and monitors the phosphine gas that is locally fumigated, ensuring the localization of the warehouse. Insects can be effectively killed, the dosage is effectively controlled, and costs are saved. During the entire process of partial fumigation and insecticide, the detection data of the local area and other parts of the warehouse can be transmitted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com