A Planar Helical Coil with Variable Turn Spacing

A technology of planar spiral coil and turn spacing, applied in the direction of transformer/inductor coil/winding/connection, transformer, transformer/inductor parts, etc., can solve the problem of poor practicability and achieve the effect of slowing down the problem of copper loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

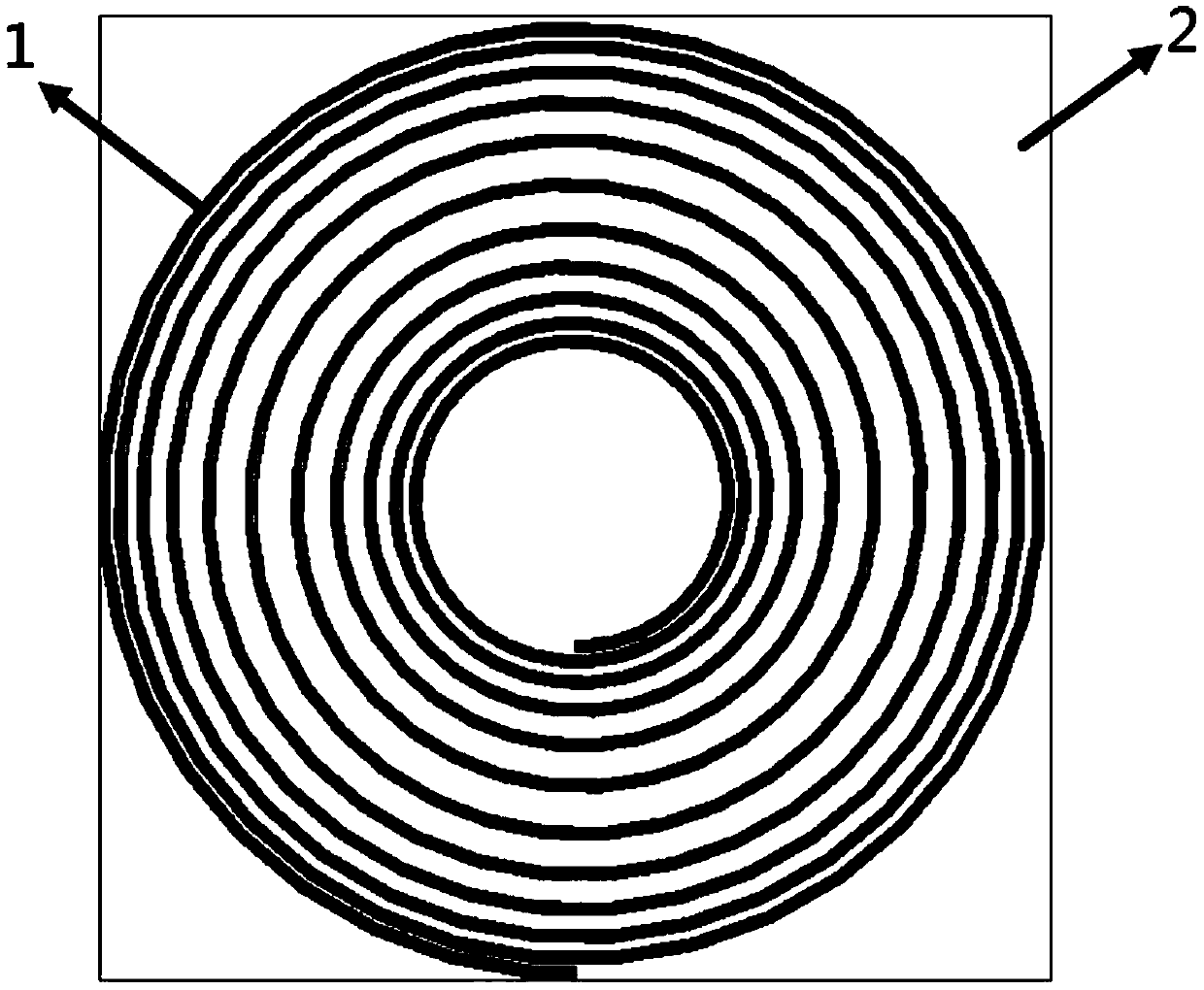

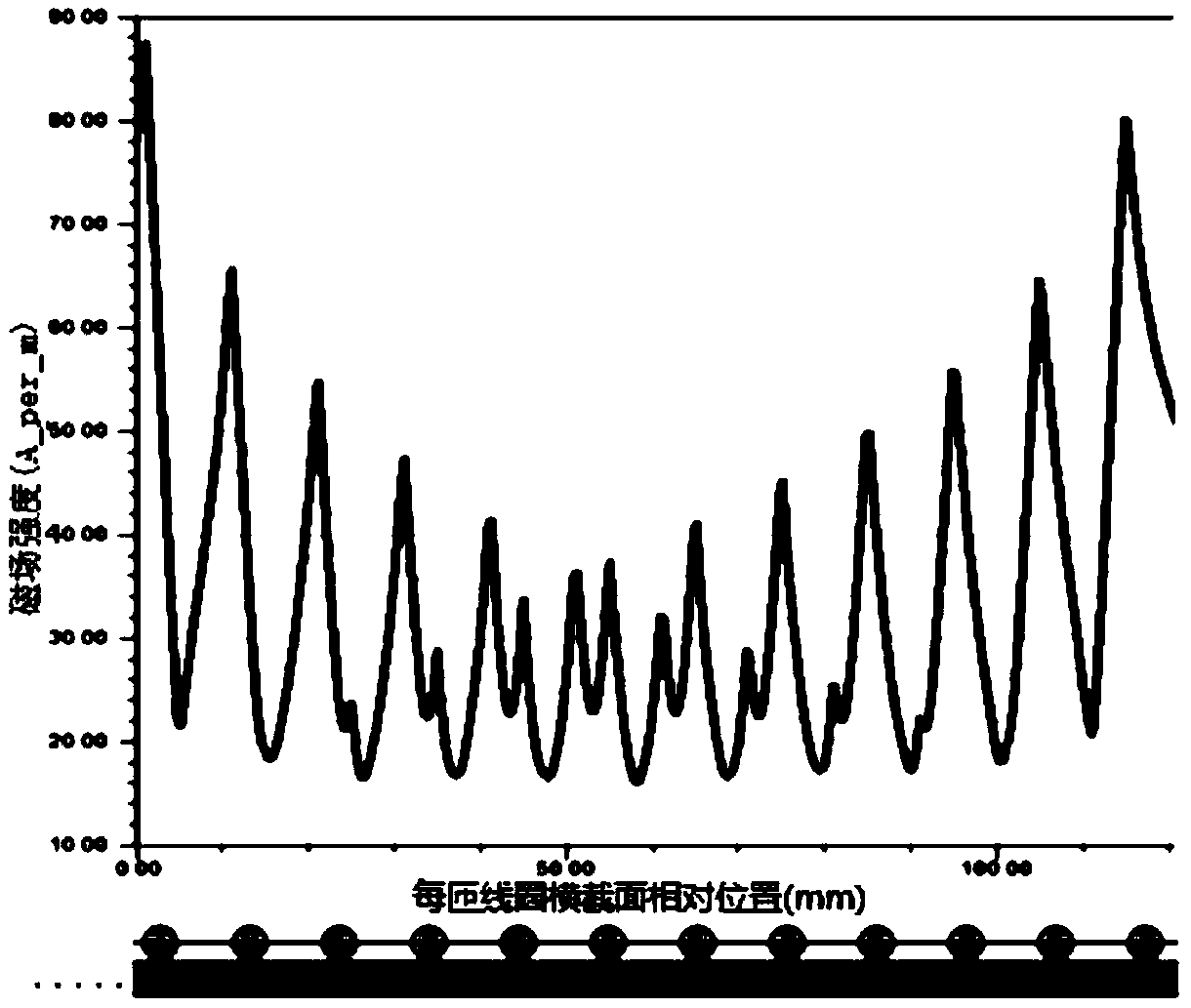

[0023] see figure 1 , figure 2 with image 3 , use a ferrite core whose contact surface can cover the outermost circle of the required coil, take the center point of the core surface as the center, and use an insulated copper wire to coil one circle in a clockwise or counterclockwise direction to obtain the regulation of equal turn spacing A planar spiral coil with inner diameter, outer diameter and number of turns; according to the changing law of the magnetic field strength amplitude of the coil distribution (that is, the magnetic field strength distribution of the coil on the side of the center of the circle presents a trend from large to small and then from small to large), select The position corresponding to the lowest valley of the magnetic field intensity amplitude in the coil is taken as the sparsest point, and with this p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com