3D food model printer

A food model and printer technology, applied in the field of machinery, can solve the problems of poor applicability and inapplicability, and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

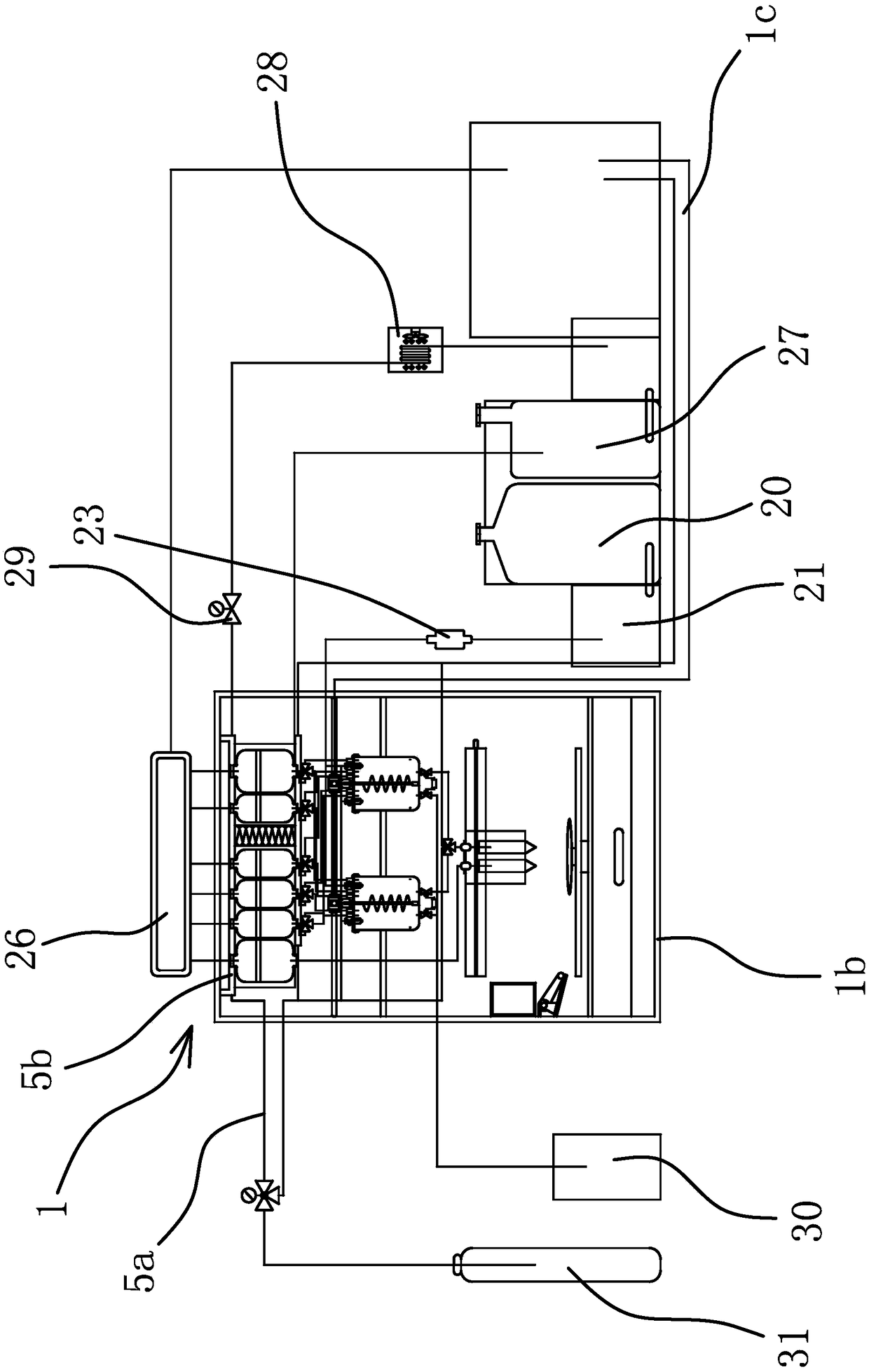

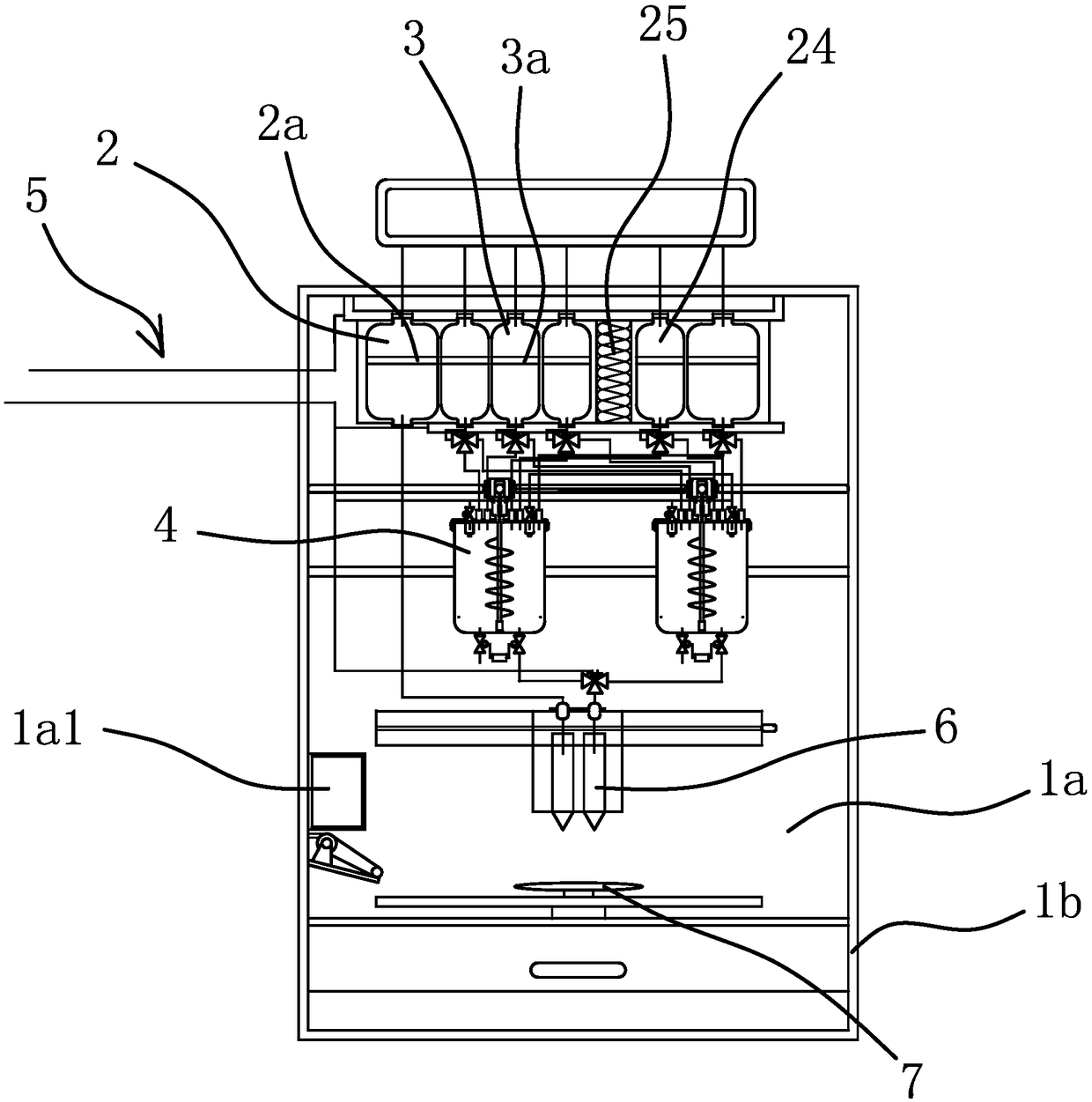

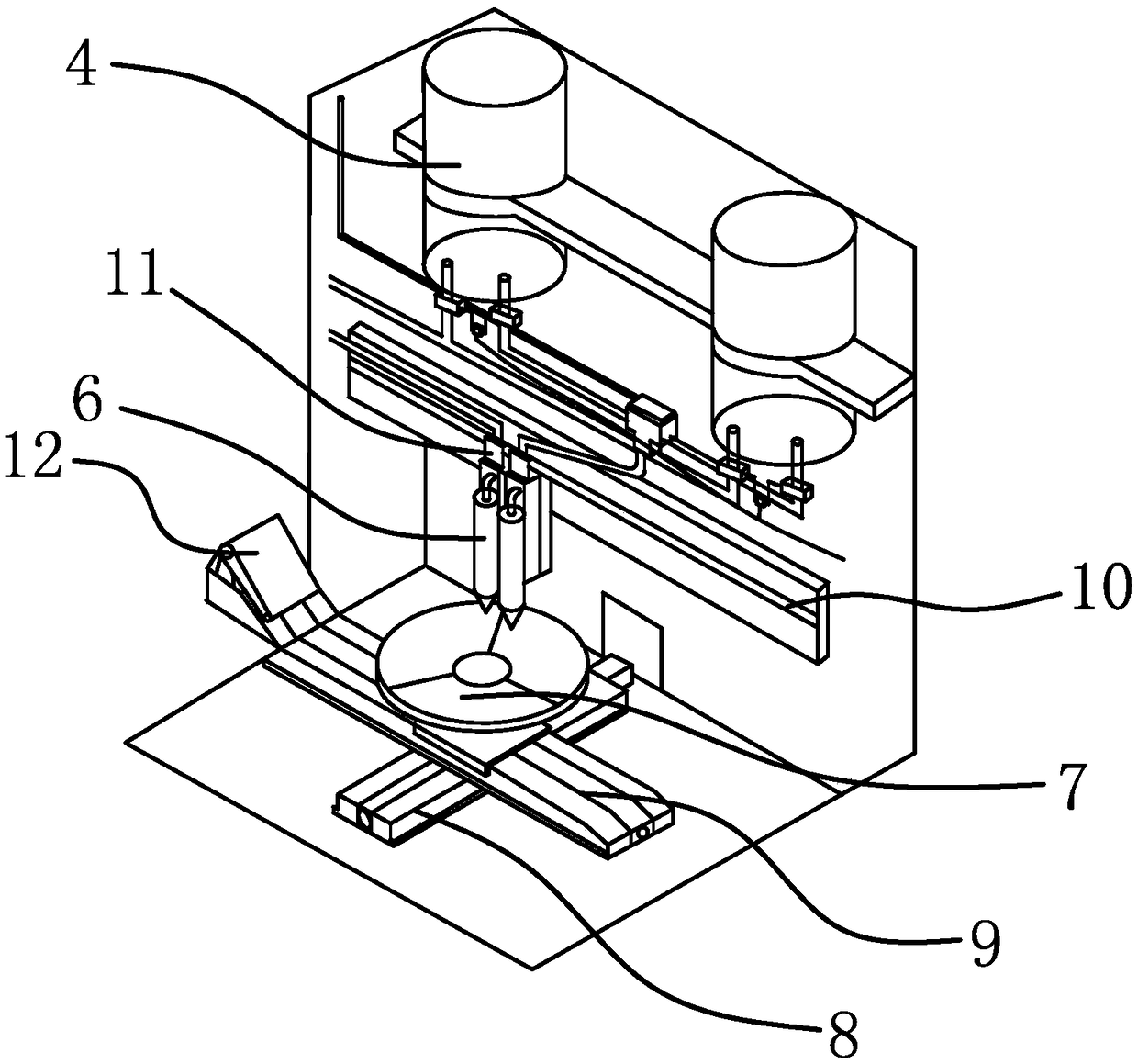

[0082] Such as figure 1 and figure 2 and image 3 and Figure 4 As shown, the 3D food model printer includes a frame 1, and also includes a printing device, a cleaning device and a stirring device connected to the frame. The stirring device can mix and stir various printing materials, and the stirring device is connected to the printing device. The mixed printing materials can enter the printing device, the printing device can use the mixed printing materials to print 3D food models, and the cleaning device can clean the stirring device.

[0083] The printing device of the 3D food model includes a frame 1, a mixing mechanism and a printing mechanism. The mixing mechanism and the printing mechanism are all connected to the frame, and the mixing mechanism can transport the mixed printing materials to the printing mechanism. , the above-mentioned printing mechanism can print out a 3D food model of a predetermined shape.

[0084] The mixing mechanism includes a main material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com