Rotor Coupling Center Alignment Disk Device for Turbine Generator Set

A technology for turbogenerator sets and disk drives, applied to shaft couplings, rigid shaft couplings, mechanical equipment, etc., can solve the problems of excessive rotor disk motion, repeated disk rework, heavy rotor weight, etc., and achieve Overcome the influence of external force and ensure the effect of consistent position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail:

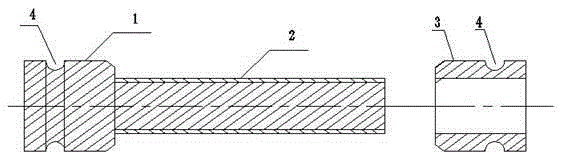

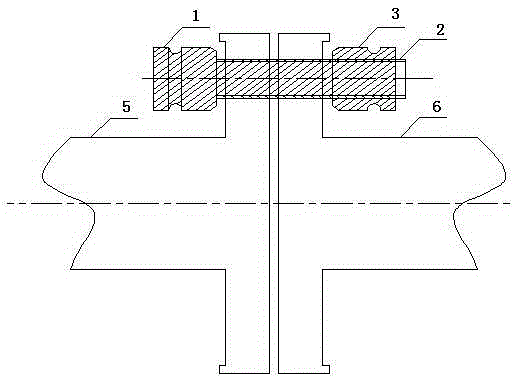

[0014] like figure 1 , 2 As shown, the present invention is a rotor coupling center alignment disk device of a turbogenerator, including a connecting shaft pin 1 . According to the different sizes of the rotors of the unit, measure the inner hole of the active rotor coupling and the thickness of the coupling respectively, and process and manufacture a suitable connecting shaft pin 1 . One end of the connecting pin is provided with a limit boss, and the other end of the connecting pin is covered with a movable wire rope bolt hanger 3, and a circle of rope grooves 4 is arranged on the circumference of the limit boss and the wire rope bolt hanger 3. The surface of the connecting shaft pin 1 is provided with a protective copper sleeve 2, which can prevent the connecting shaft pin 1 from causing mechanical damage to the inner hole of the precise rotor coupling.

[0015]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com