Laser beam and machine tool shaft moving direction parallelism adjusting method

A technology of moving direction and debugging method, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of high cost and cumbersome adjustment process, and achieve the effect of simple operation, wide application range, and fast and simple adjustment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

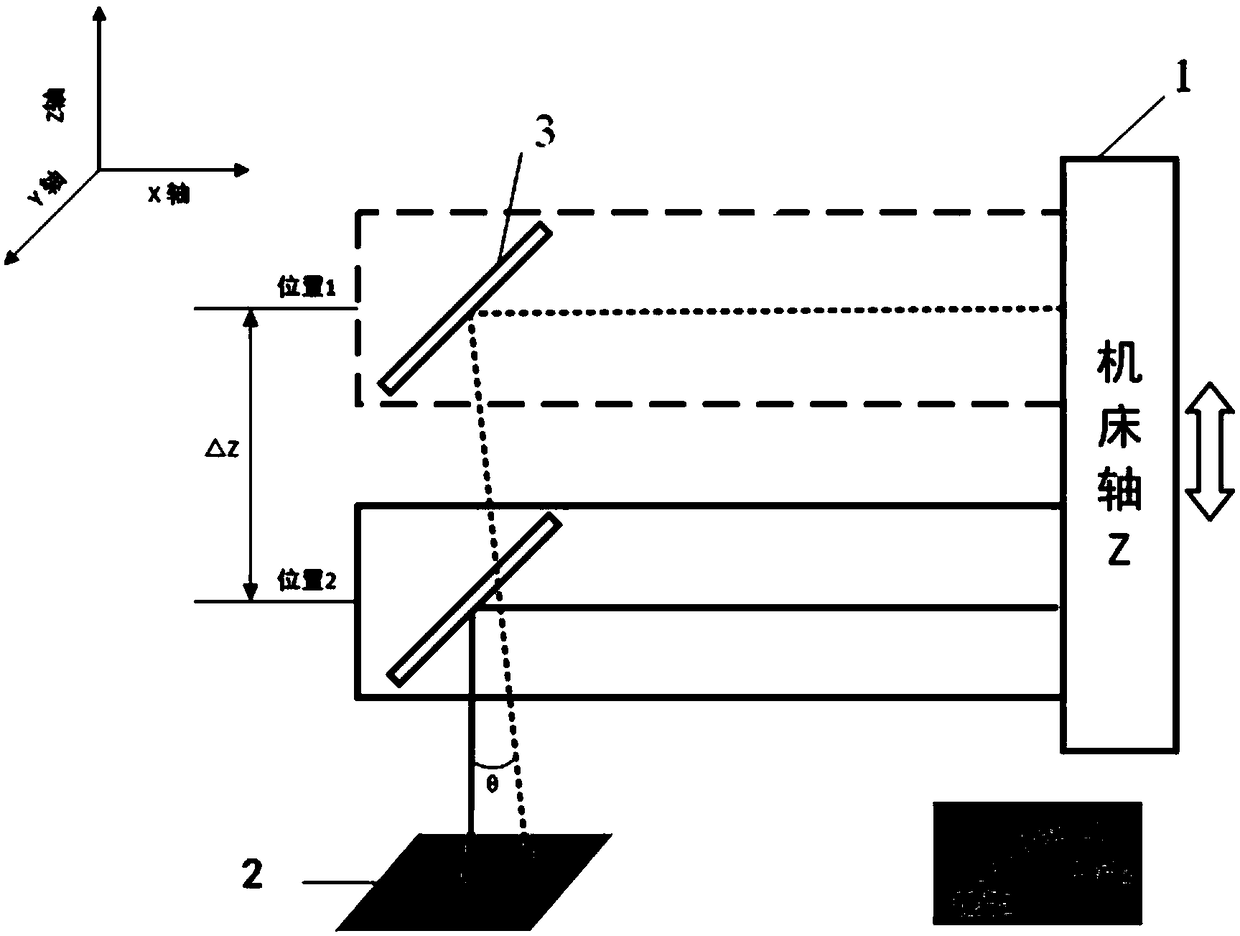

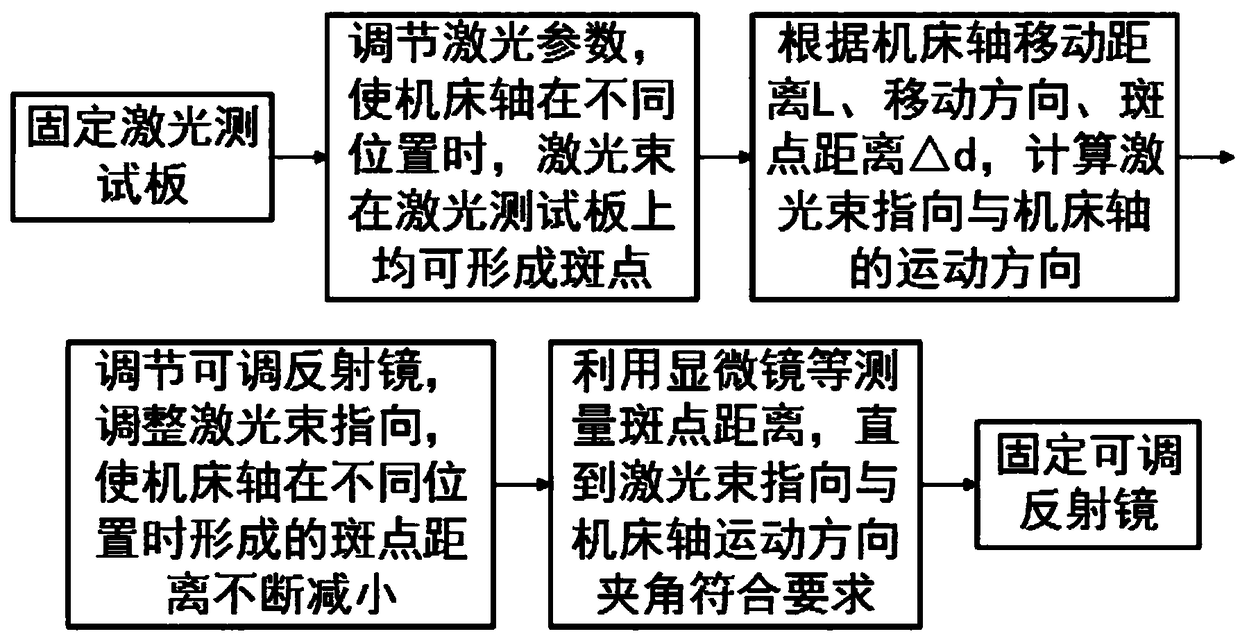

[0030] like figure 1 As shown, the inventive method drives the adjustable reflector to move through the machine tool shaft, and the laser beam passing through the reflector 3 forms spots on the fixed laser test board 2, and judges the relationship between the laser beam and The included angle of the movement direction of the machine tool axis is used to adjust the angle of the adjustable mirror to adjust the laser pointing. In addition, the above method can also be used to measure the position of the spot formed by the laser beam on the laser test board when the machine tool shaft is at different positions with the help of a high-magnification microscope, so that the adjustment of the laser beam is more accurate, and the direction of the laser beam and the machine tool shaft can be adjusted. parallel purpose. Therefore, the meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com