Disassembly tooling and method for vortex reducer assembly

A vortex reducer and component technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problem of inability to fasten vortex reducer components well, reduce the risk of deformation, facilitate fastening, and has high feasibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

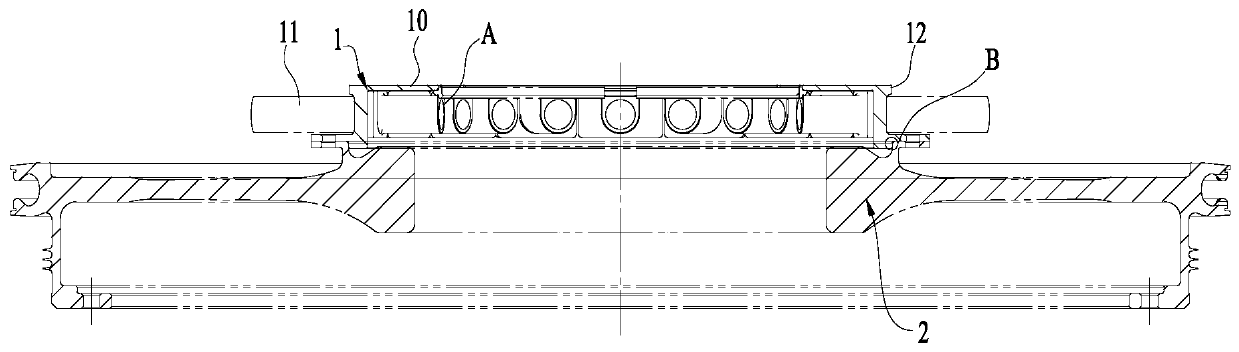

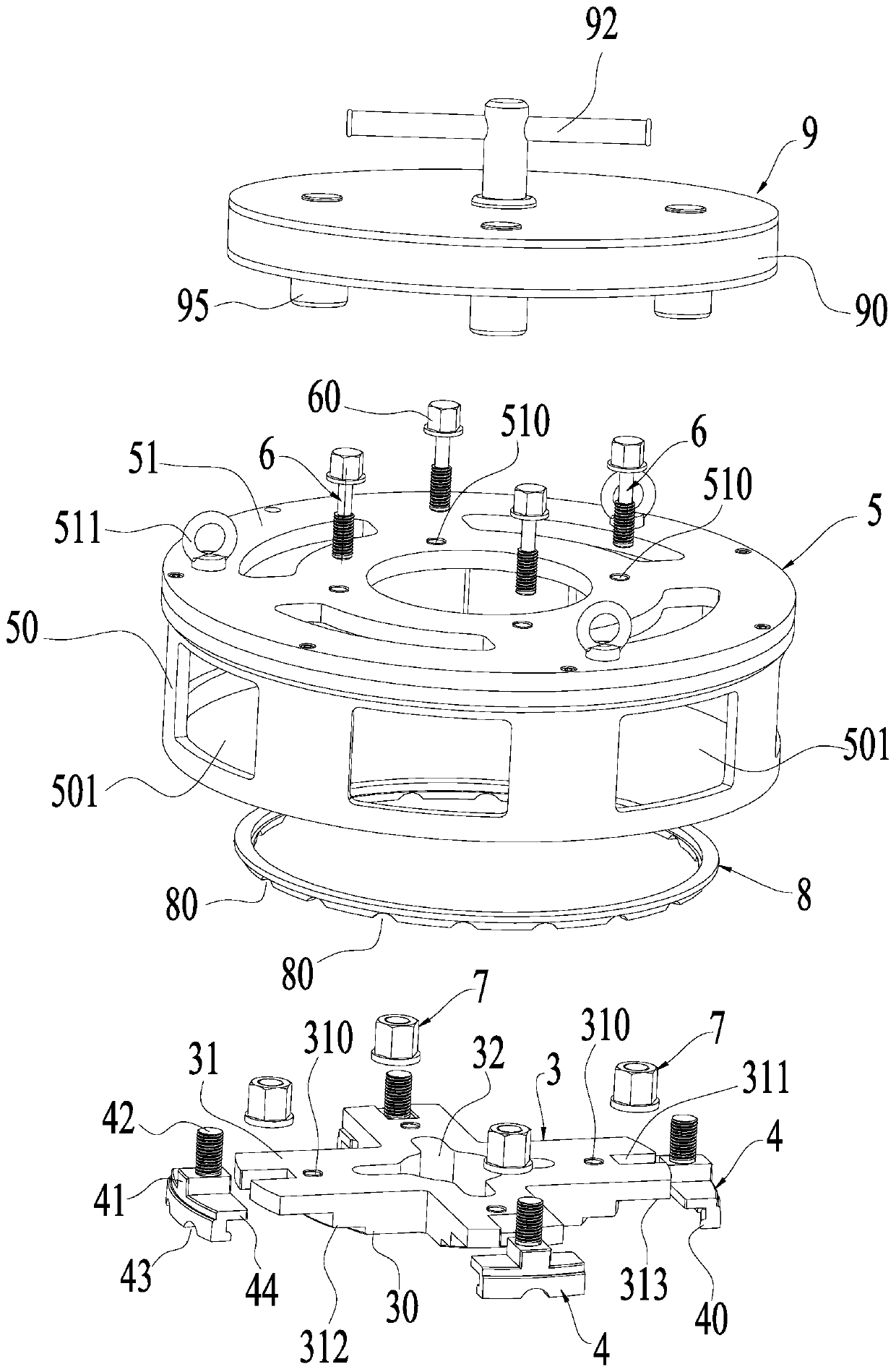

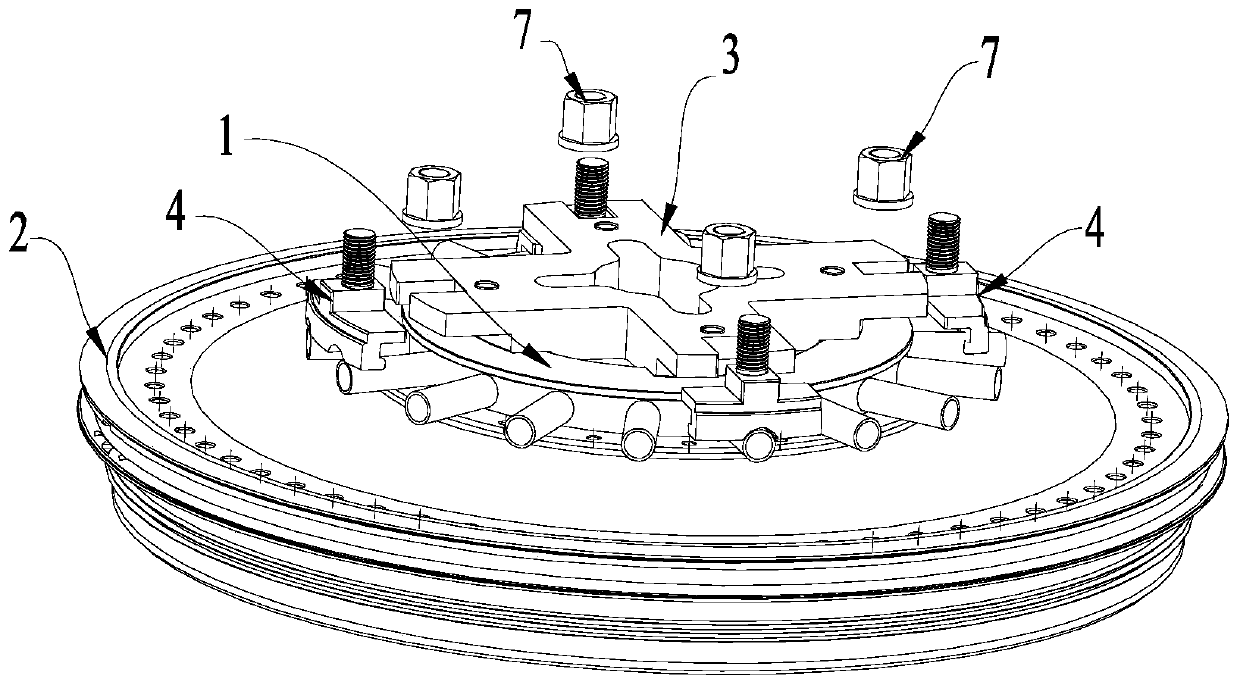

[0043] refer to figure 2 , the present invention provides a vortex reducer assembly disassembly tool for disassembling the vortex reducer assembly 1 from the primary disc 2 . The disassembly tooling of the vortex reducer assembly of the present invention includes a support plate 3, which is used for centering cooperation with the support ring 10 of the vortex reducer assembly 1 and resting on the support ring 10 for support and force transmission during the process of decomposition and force application; pull hooks 4. It is used to fix the support plate 3 on the outer convex part 12 of the support ring 10 so that the support plate 3 and the vortex reducer assembly 1 are fixed as a whole; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com