Automatic press-fitting device of starter planetary shafts

A press-fitting device and planetary shaft technology, applied in the field of press-fitting devices, can solve the problems of single assembly process, poor assembly accuracy, low work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

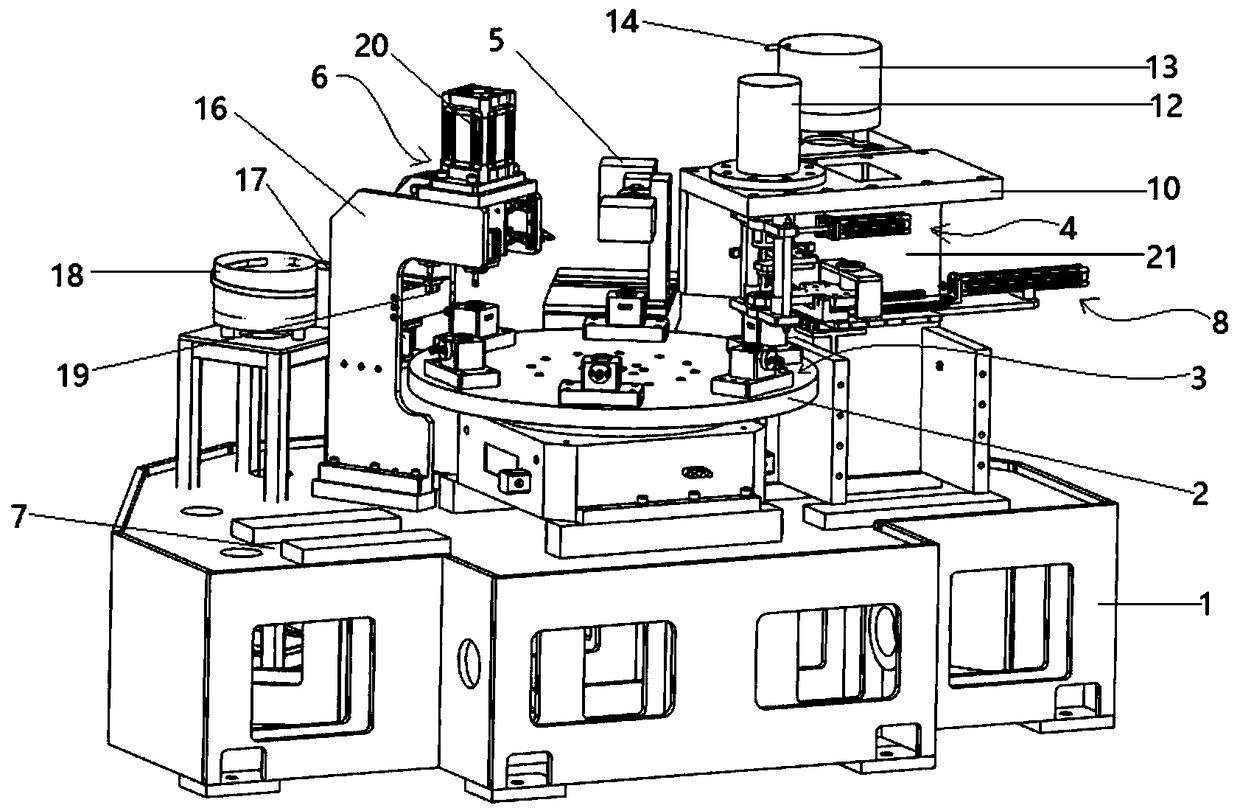

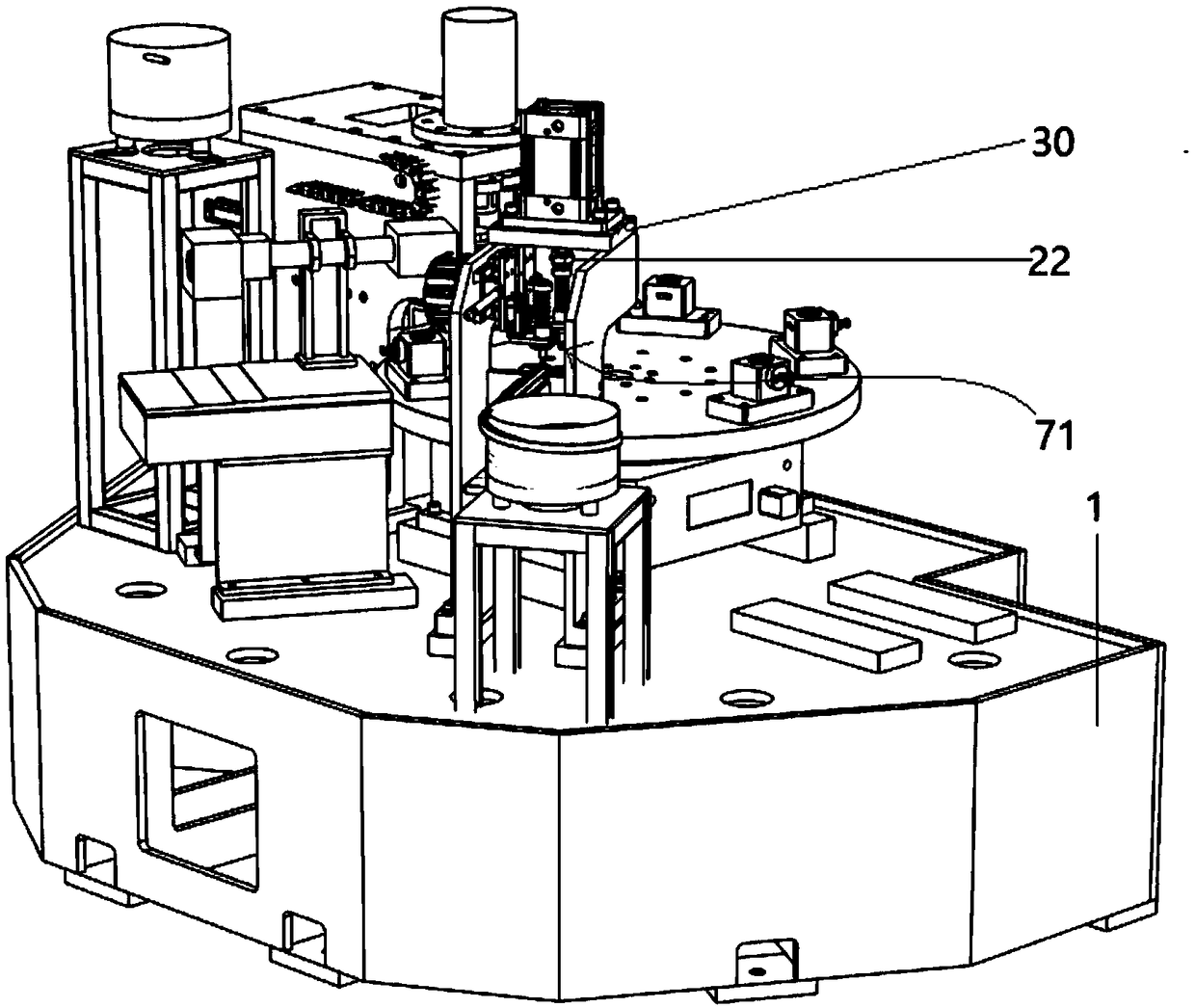

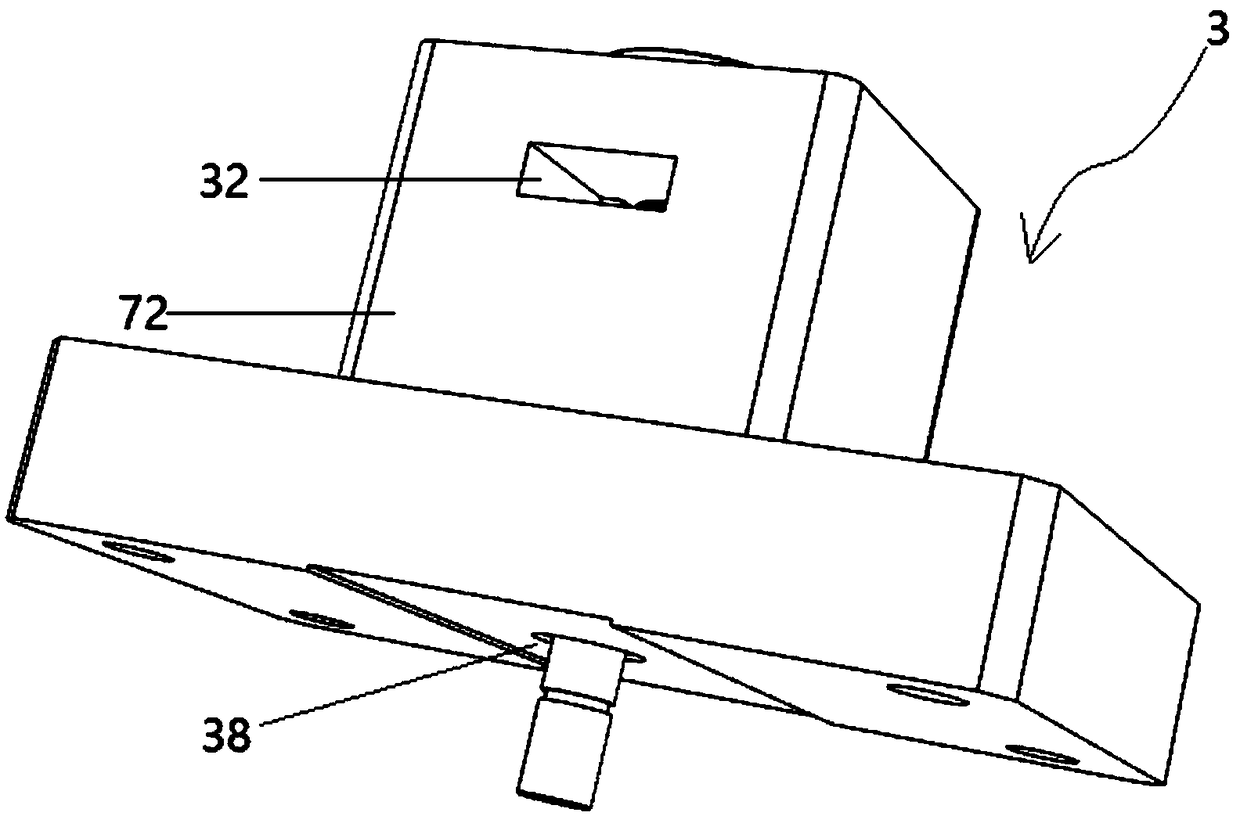

[0045] combine figure 1 and figure 2 As shown, a starter planetary shaft automatic press-fitting device in this embodiment includes a frame 1, a hydraulic rotary platform 2 and a pin pressing component 4, wherein the hydraulic rotary platform 2 is a multi-station equally divided rotary platform, and each The planetary shaft clamping tooling 3 for clamping the planetary shaft is installed on the stations, and the pinning part 4 is installed at the pinning station of the hydraulic rotary platform 2; the pinning part 4 includes a pin vibrating tray 13, a hydraulic cylinder 12. The pin delivery mechanism 8, the fixed pin mechanism 69 and the pin stabilization mechanism 9, the pin vibrating material tray 13 is connected with the pin delivery mechanism 8, and is used to send the pins into the pin delivery mechanism 8 after sorting according to the specified direction, and the pin delivery mechanism 8 Set on one side of the pin pressing station, it is used to send the pins to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com