Oilstone clamping and feeding device for roller lapping machine

A technology of feeding device and lapping machine, which is applied in the direction of grinding drive device, grinding machine parts, working carrier, etc., can solve the problems of increased production cost, low product yield, and broken oilstone, and achieves improved grip. The effect of maintaining stability, convenient and quick operation, and reducing the width of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

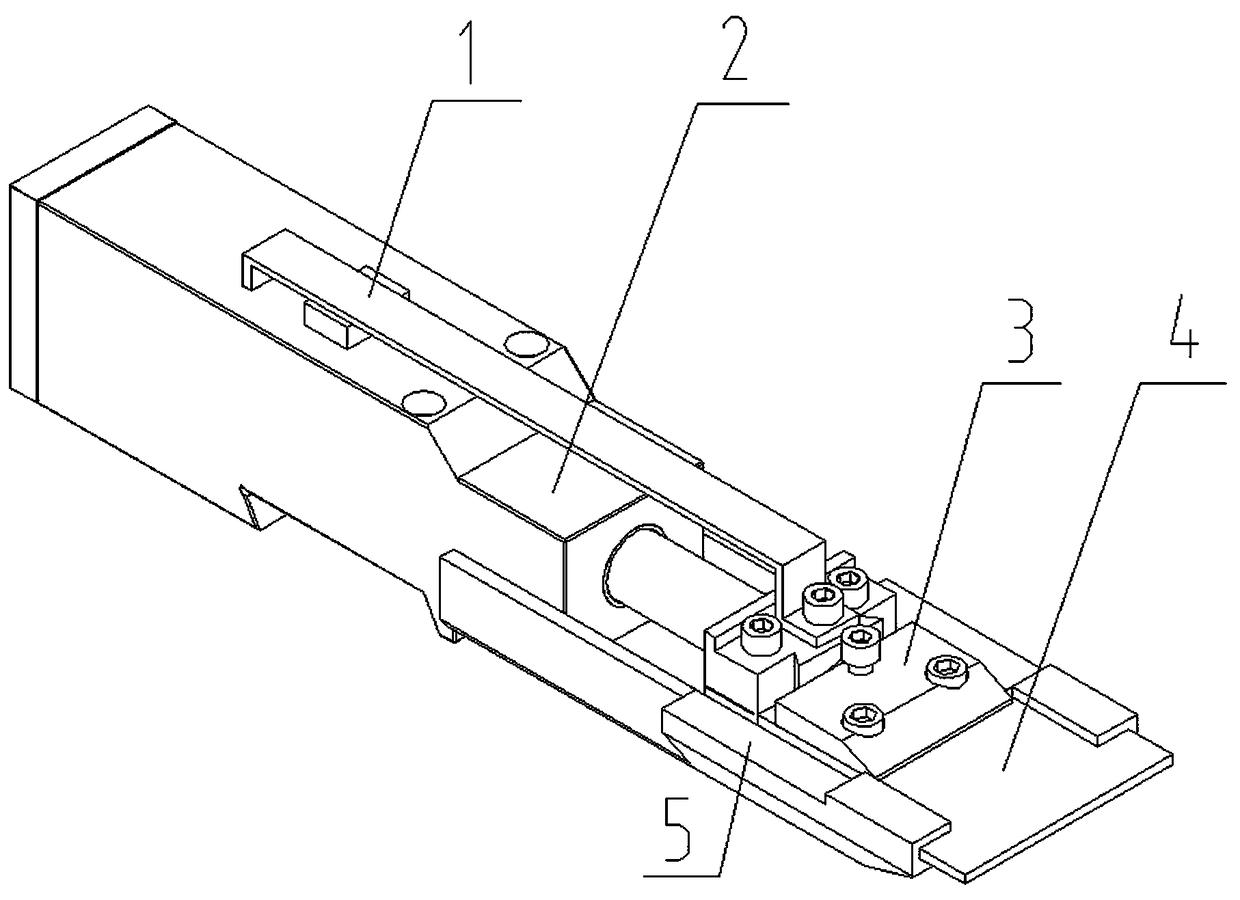

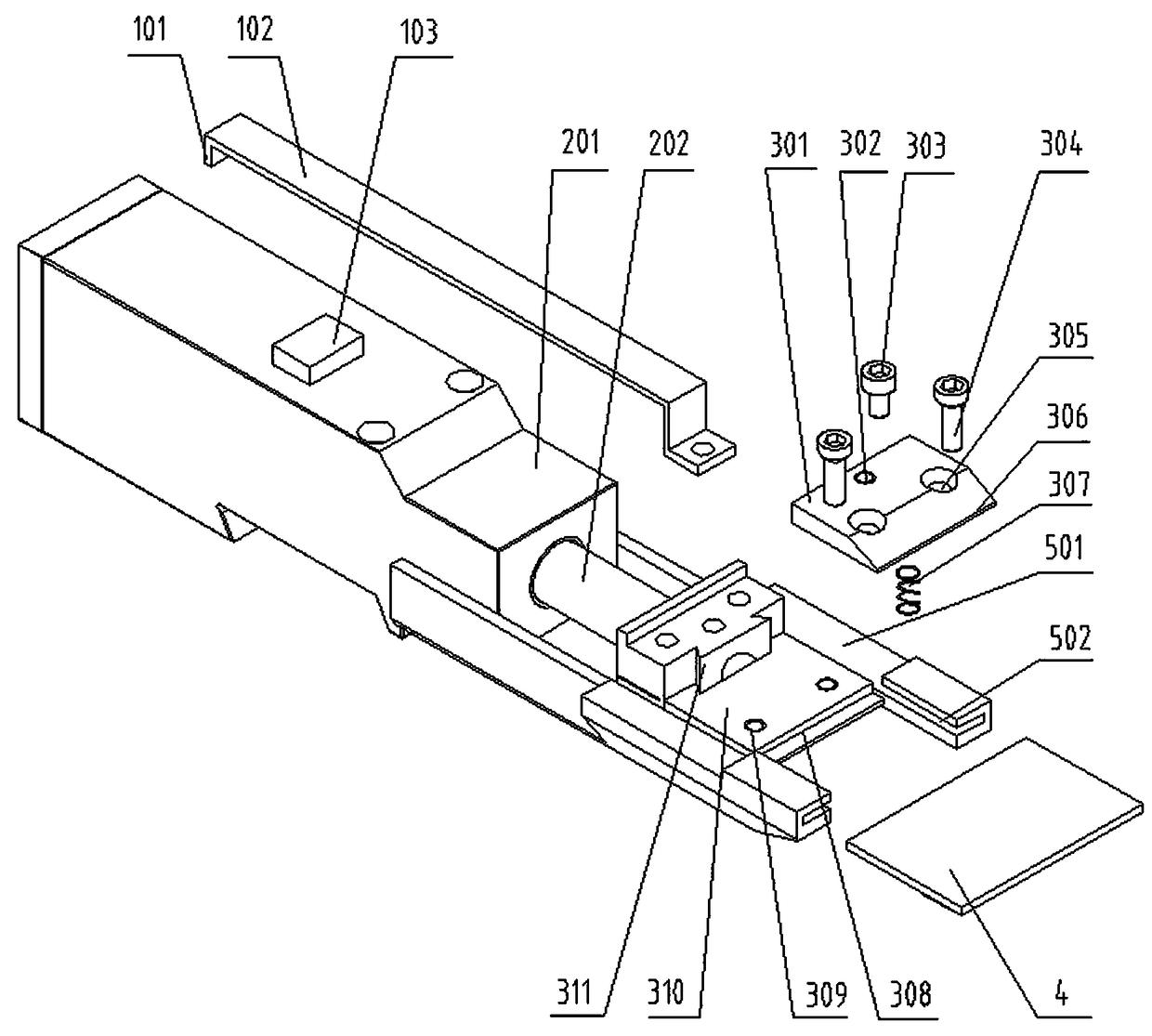

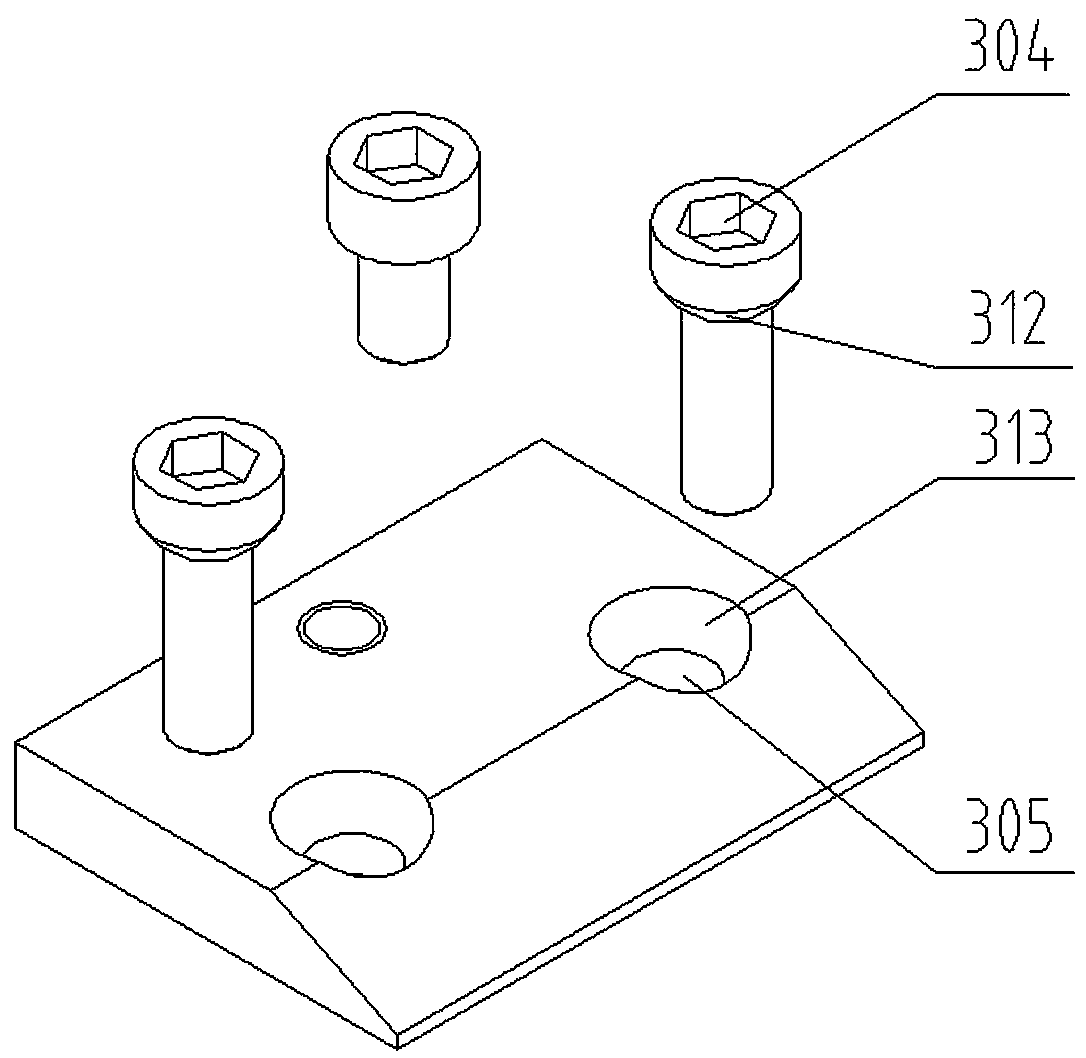

[0024] Such as figure 1 and figure 2 As shown, a whetstone 4 clamping and feeding device for a roller lapping machine of the present invention includes a constant pressure feeding mechanism 2 . The constant pressure feeding mechanism 2 may include a cylinder body 201 and a piston rod 202 pierced in the cylinder body 201, and the piston rod 202 may continue to extend toward an oil cylinder, an air cylinder, an electric push rod protruding from the cylinder body 201 with a constant pressure or other components with similar functions. The piston rod 202 is provided with a fixing clip 3 for clamping and fixing the oil stone 4 , and the cylinder body 201 is provided with a guide seat 5 for feeding the oil stone 4 along with the piston rod 202 . Through the constant pressure feed mechanism 2, the grinding oil stone 4 can be pressed against the roller to be ground, and the oil stone 4 can be pushed forward after the oil stone 4 is worn, so as to ensure a constant pressure during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com