Flexible fixture for coating bearing roller

A flexible fixture and rolling element technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of uneven force on rolling elements, affecting the working life of bearings, and insufficient coating. , to achieve the effect of small clamping area, uniform coating effect and production cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

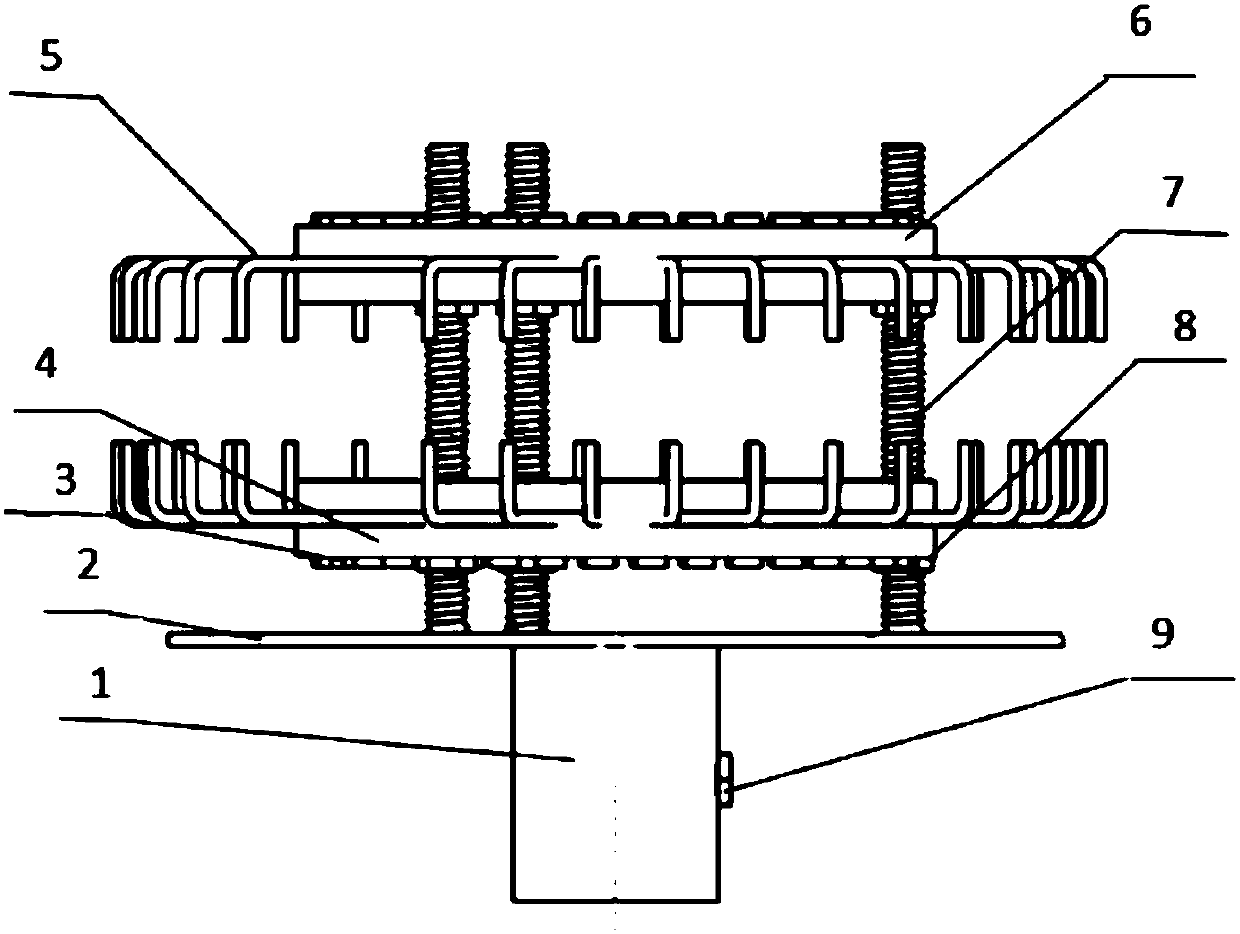

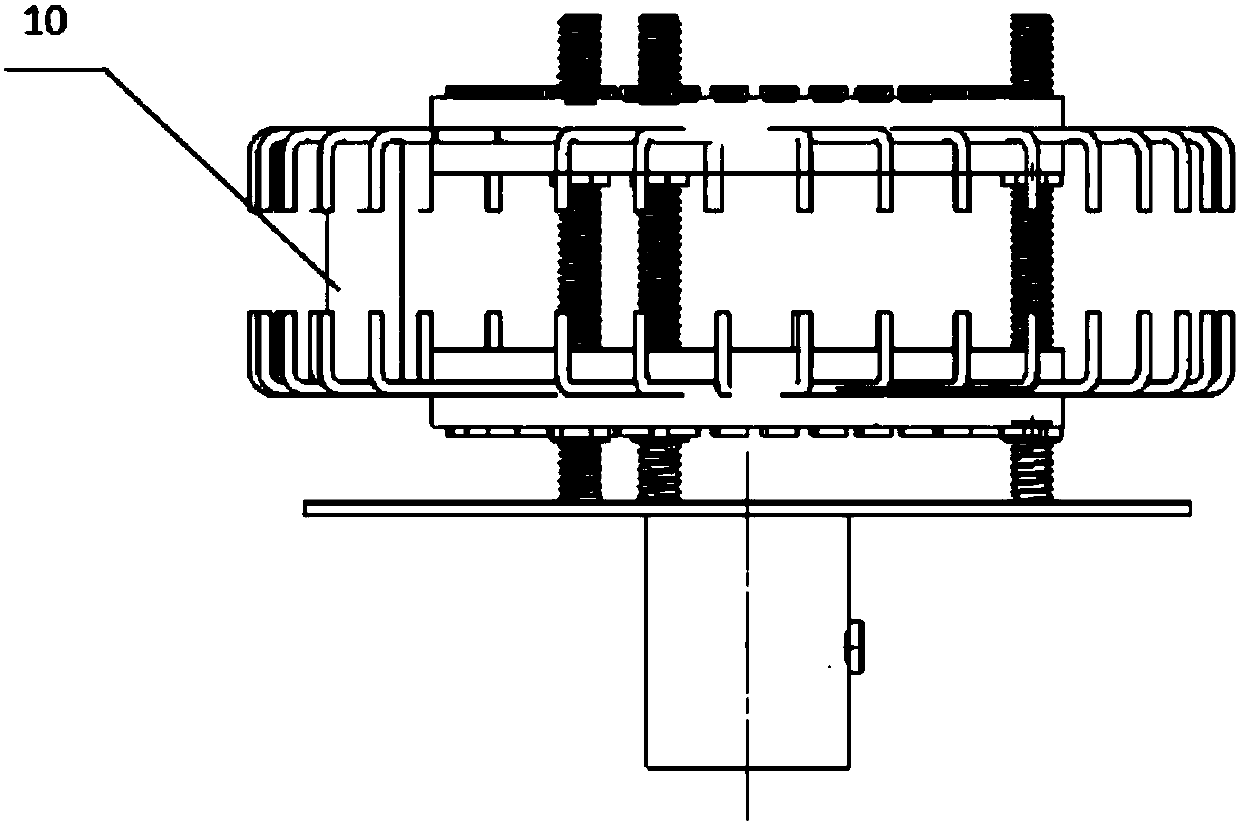

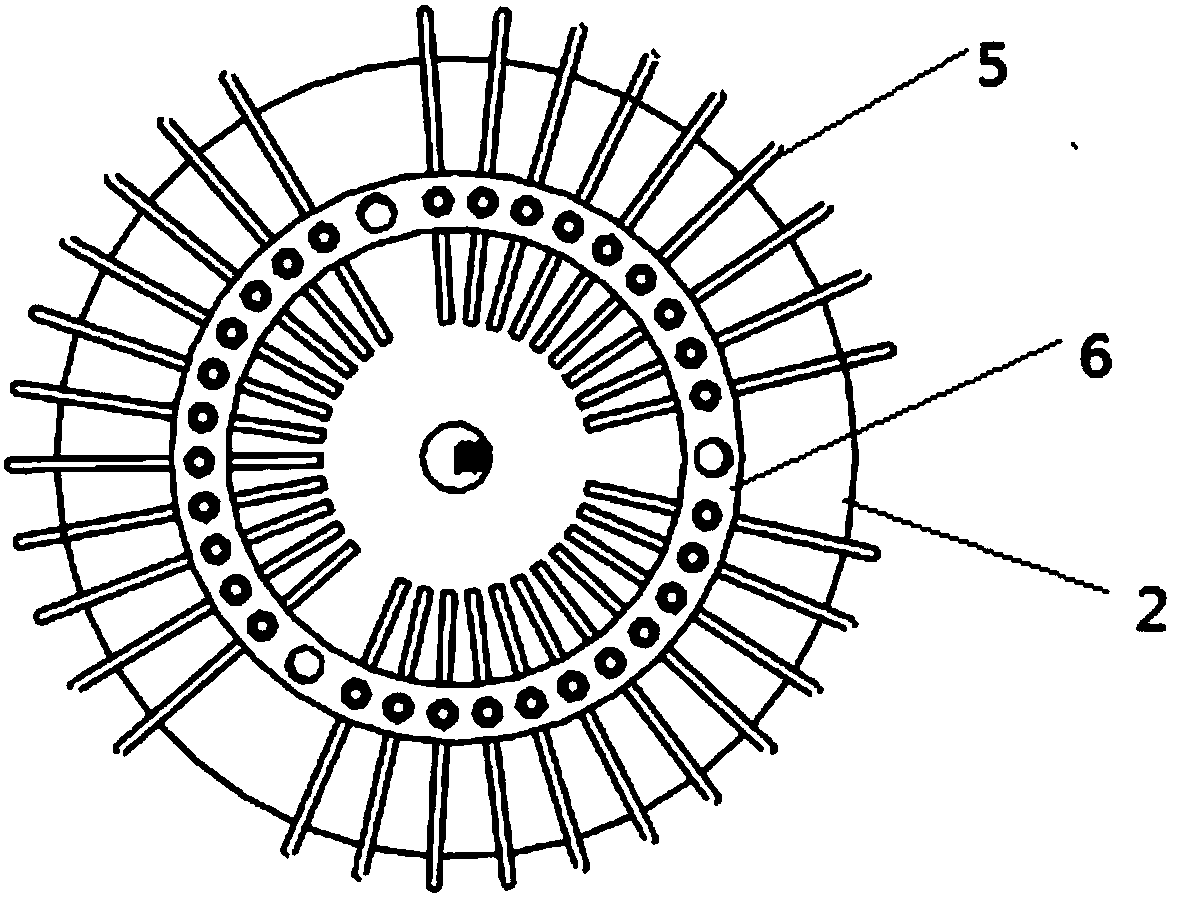

[0029] A flexible fixture for coating bearing rolling bodies, including an upper disc 6, a lower disc 4, and several bearing rolling body support bars 5, the upper disc 6 and the lower disc 4 pass through a plurality of double heads The stud 7 is connected, and the distance between the two discs can be adjusted according to the height of the rolling body by adjusting the nut 8. When the workpiece is fixed, the nuts are tightened, and the outer surfaces of the upper disc 6 and the lower disc 4 are opened There are several sockets, the bearing rolling body support bar 5 is sleeved in the socket, and the bearing rolling body support bar 5 is fixed to the upper disc 6 and the lower disc 4 by hexagon socket bolts 3 , the hexagon socket bolt 3 can adjust the extension length of the bearing rolling body support bar 5 according to the diameter of the bearing rolling body 10, increase the exposed area of the matrix, and make the surface coating of the bearing rolling body 10 more suff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com