An intelligent vibrating method for high-strength concrete members

A concrete, high-strength technology, used in ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of increased operation difficulty, omission of vibration, poor fluidity of concrete materials, etc., to improve the quality of vibration and reduce the difficulty of operation. , the effect of shortening the vibrating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

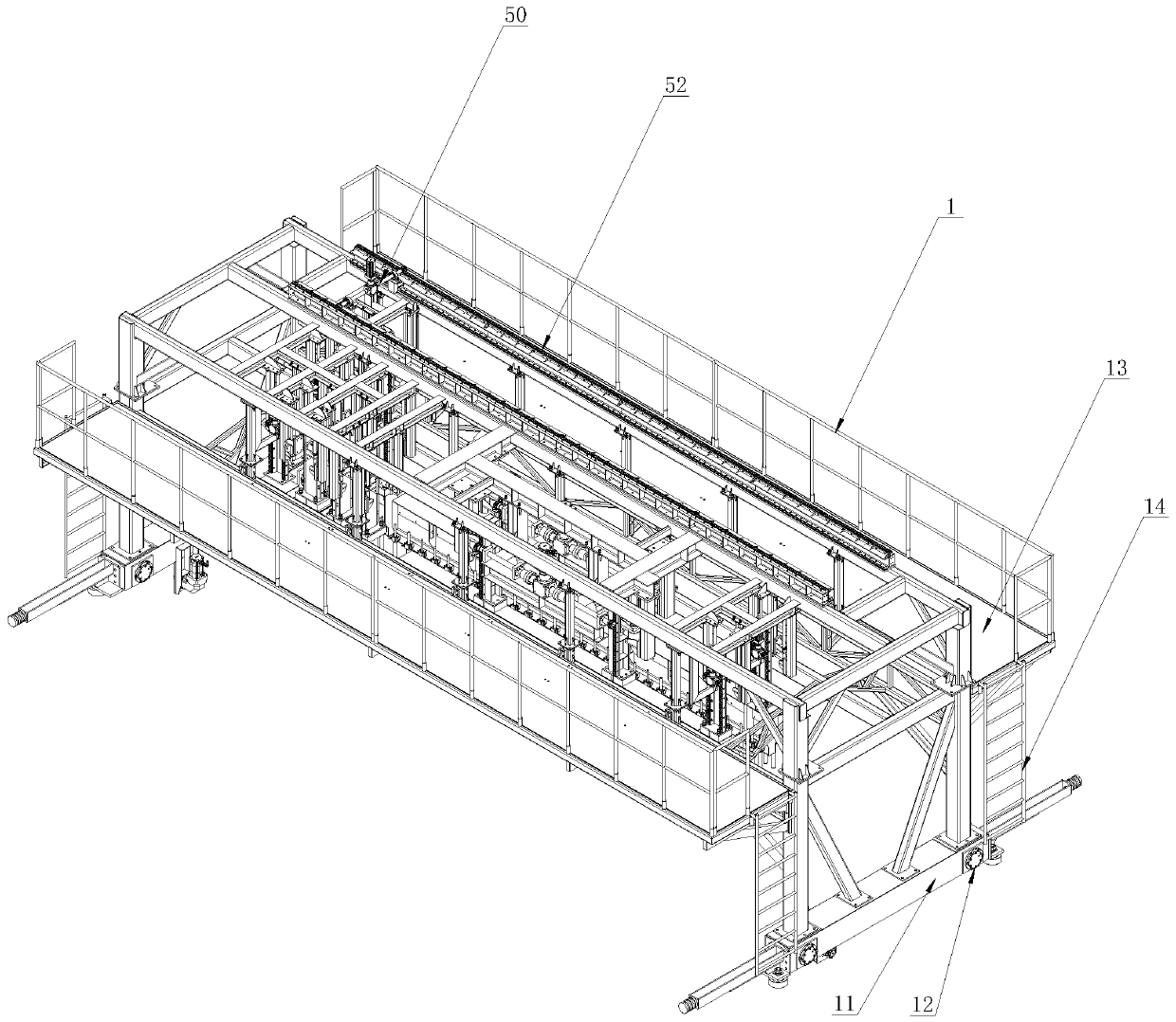

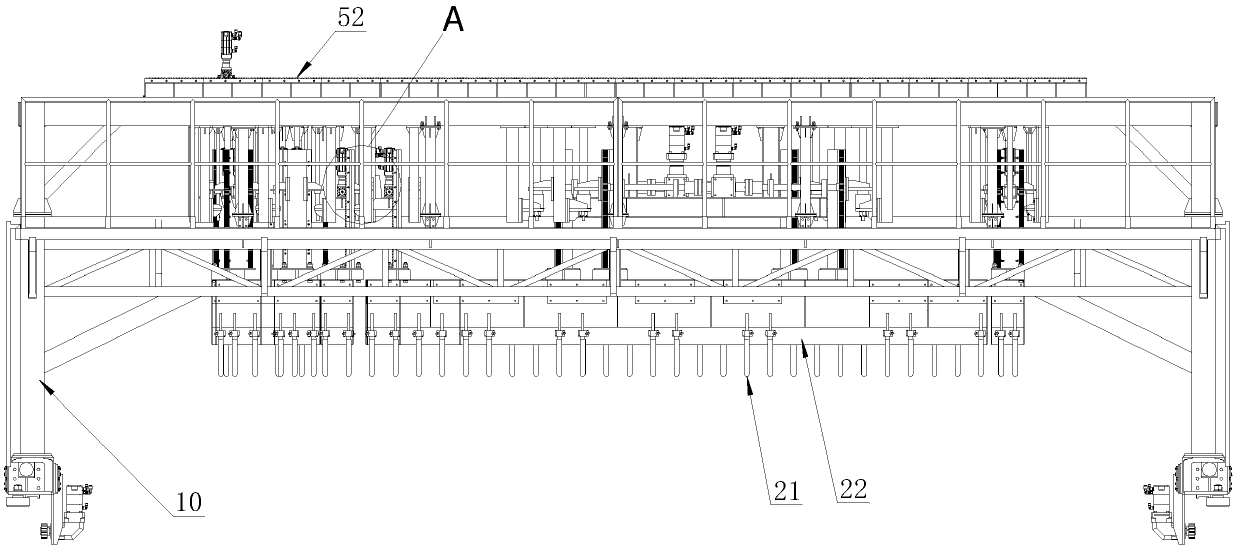

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

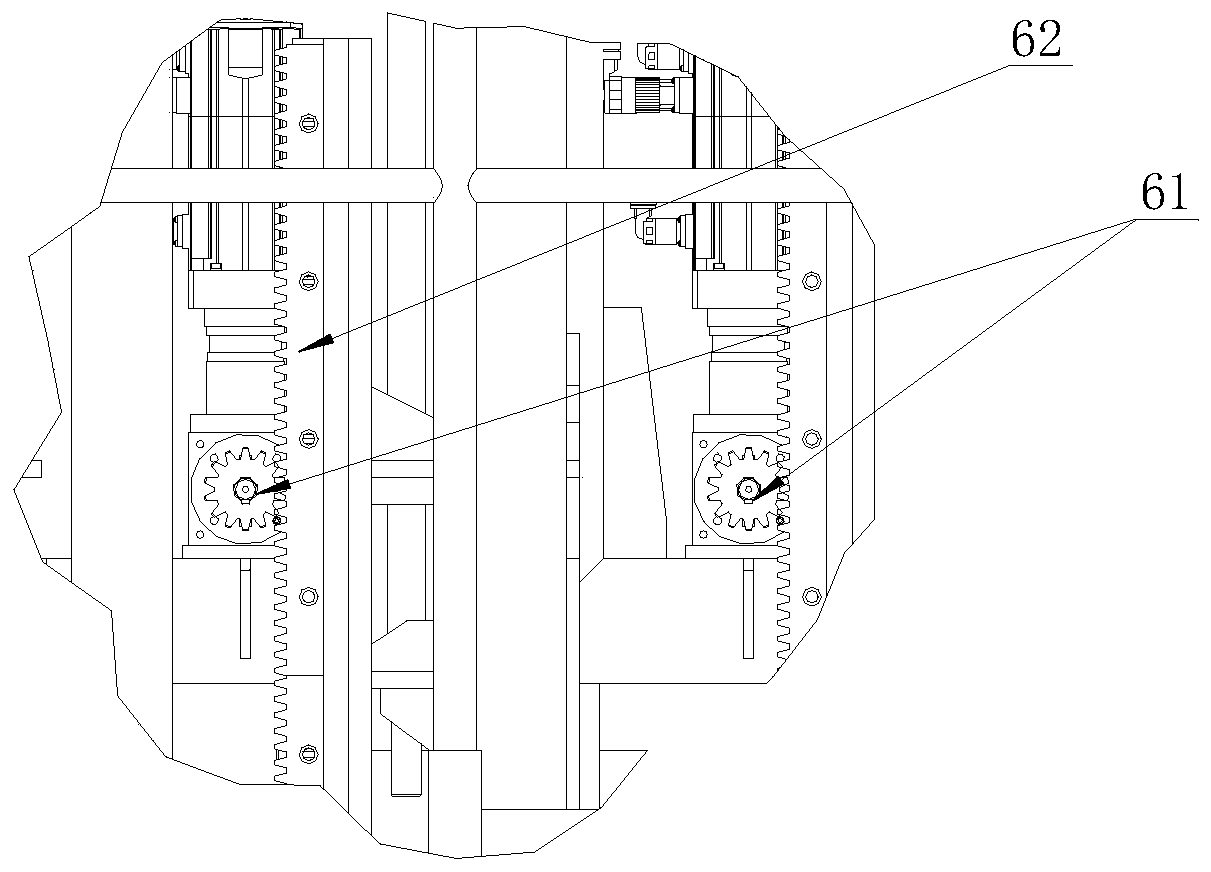

[0033] As shown in the figure, the concrete vibrating equipment used in the present invention includes a vehicle frame 1. The vehicle frame 1 includes a door frame body 10 and a vehicle frame traveling mechanism installed on the door frame body 10. The vehicle frame is provided with a PLC control system; the gantry body 10 is provided side by side along its width direction with an end tenon vibrator 20 , a middle vibrator 30 and a vibrator 40 ;

[0034] The tenon vibrator 20 includes a plurality of tenon vibrating rods 21 suspended at intervals along the length direction of the door frame body 10, and the tenon vibrating rods 21 are driven to move up and down by the tenon lifting system;

[0035] The central vibrator 30 includes a plurality of central vibrating rod groups 31 suspended at intervals along the length direction of the door frame body 10, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com