Glaze spraying system

A glaze and spraying room technology, which is applied in the field of ceramic production, can solve the problems of inconvenient operation and large investment in equipment, and achieve the effects of saving investment, avoiding random splashing, and eliminating the need for manual handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

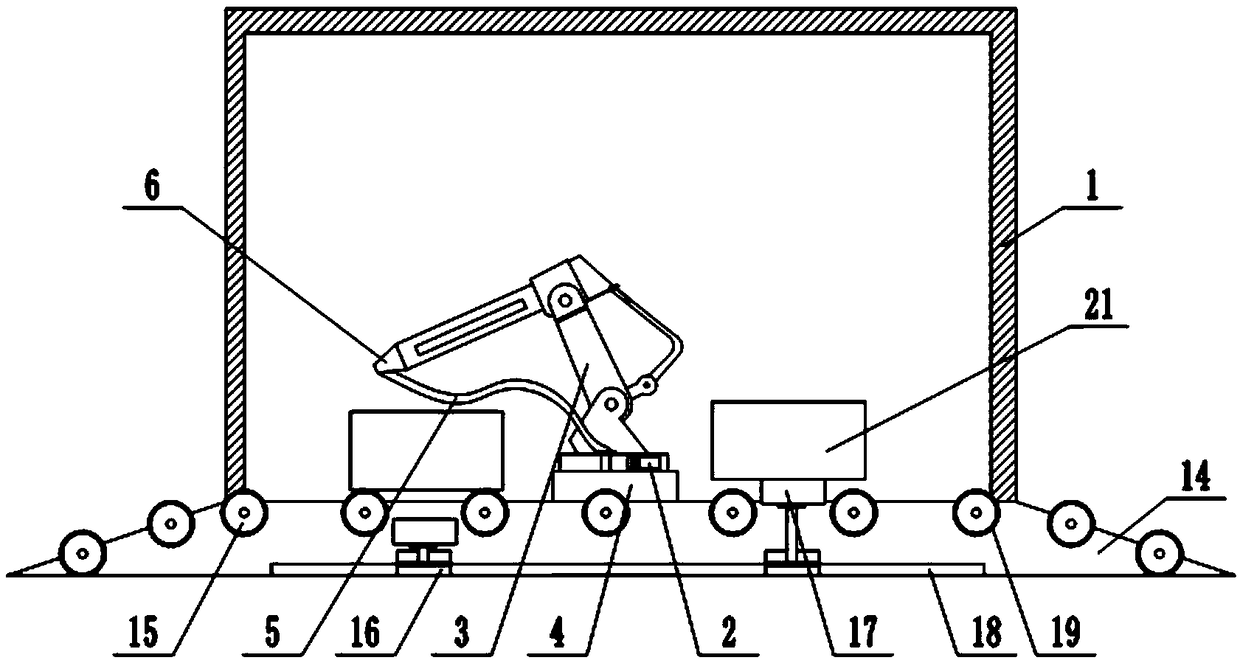

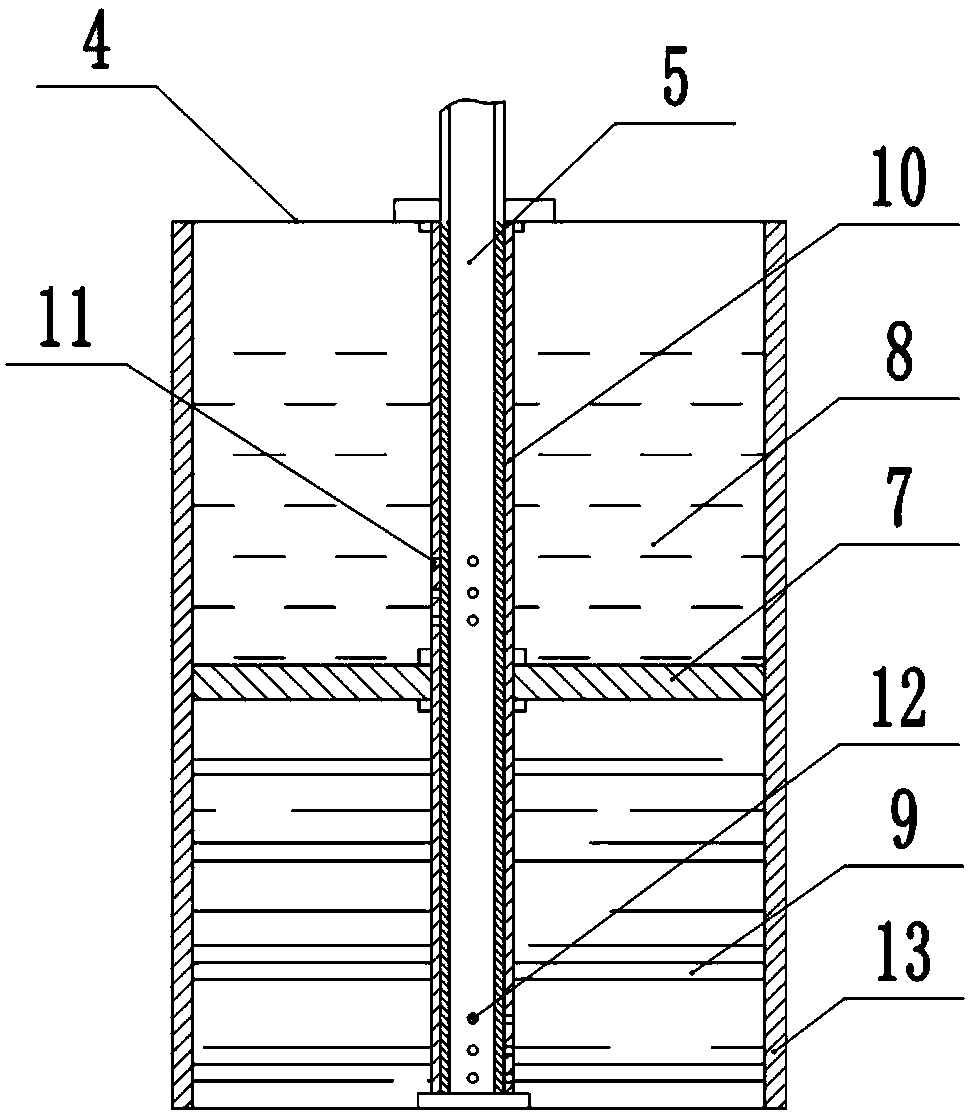

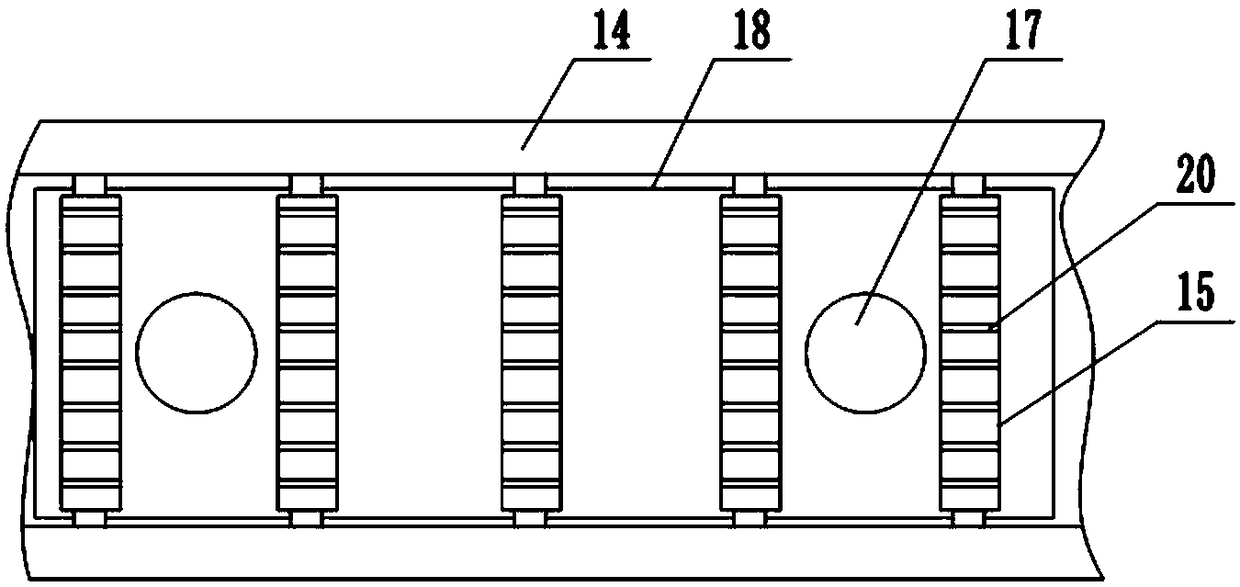

[0025] The reference signs in the accompanying drawings of the specification include: spray booth 1, controller 2, glaze spray robot arm 3, glaze material storage box 4, glaze spray tube 5, spray head 6, partition 7, white glaze chamber 8, aseptic glaze Cavity 9, conversion pipe 10, conversion hole 11, glaze spray hole 12, insulation layer 13, support platform 14, conveying roller 15, lifting cylinder 16, rotary table 17, material receiving tray 18, anti-skid layer 19, material guide groove 20, Toilet 21.

[0026] The embodiment is basically as attached figure 1 Shown: Glaze spraying system, including spray booth 1 and conveying device. The left and right ends of the spraying chamber 1 are respectively provided with an inlet and an outlet, and the conveying device runs through the spraying chamber 1 and communicates with the inlet and the outlet. A glaze spraying device is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com