Sleeve rubber mold without trimming

A kind of rubber mold, no flash technology, used in home appliances, other home appliances, household components and other directions, can solve the problem of mold flash, avoid flash, improve utilization and production efficiency, save rubber materials and labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

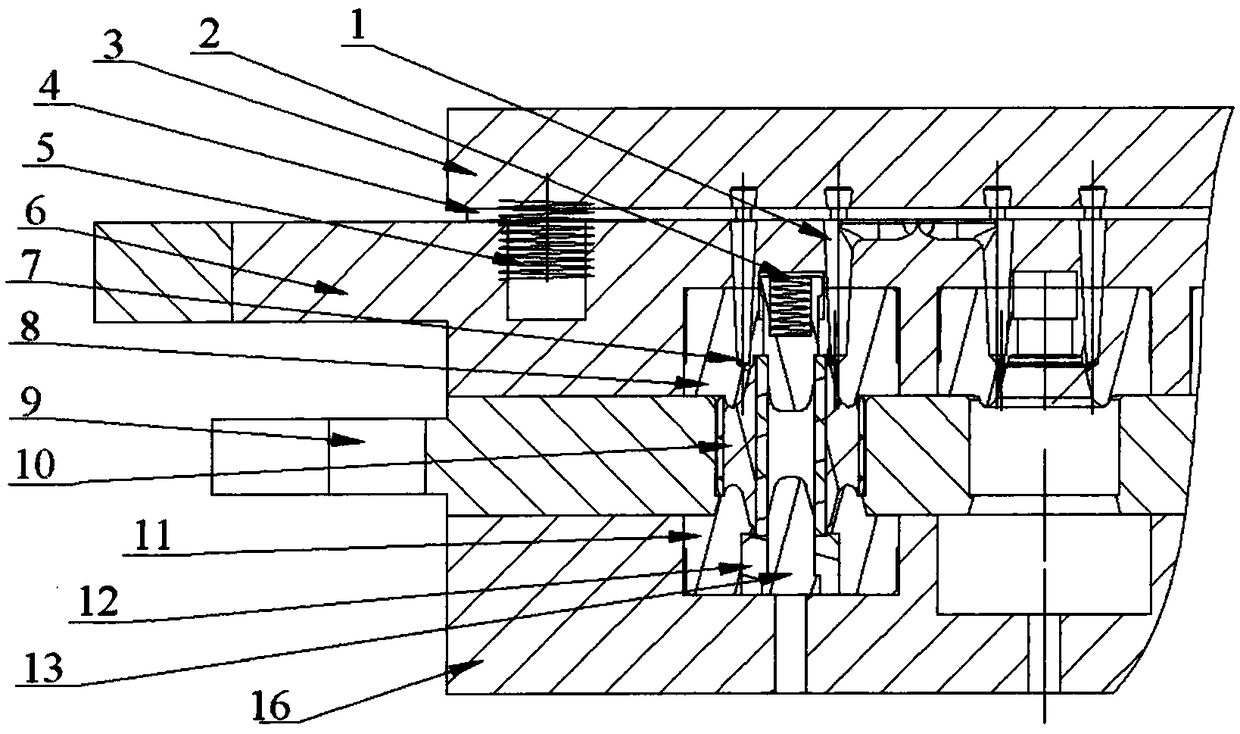

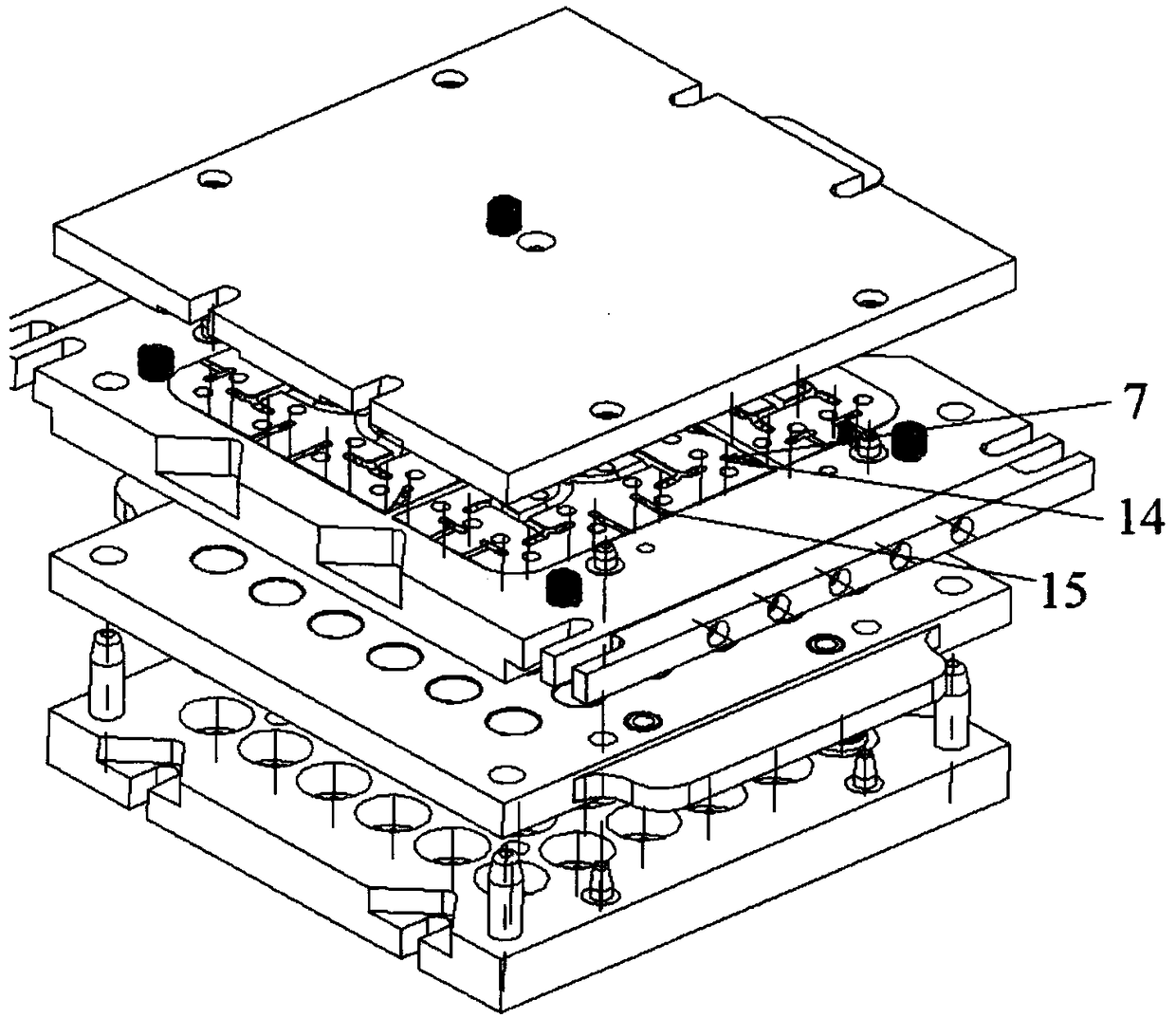

[0015] The invention is a rubber mold with no flash structure for the bushing, such as figure 1 , figure 2 As shown, it includes an upper formwork 6, the top of the upper formwork 6 is provided with a runner plate 3, and a discharge plate 4 and a spring 5 are arranged between the upper formwork 6 and the runner plate 3; the springs 5 are arranged on the upper formwork evenly In the groove around 6; the unloading plate 4 is located in the middle of the upper template 6. The bottom of the upper formwork 6 is connected with the lower formwork 16 through the middle formwork 9, the bottom of the upper formwork 6 is provided with an upper groove, the bottom of the lower formwork 16 is provided with a lower groove, and the upper groove and the lower groove are respectively provided with an upper mold The insert 8 and the lower mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com