Discharging shifting device of feeding machine for brake calipers of brake pumps

A technology of shifting device and brake caliper is applied in the field of unloading shifting device of brake pump brake caliper feeding machine, which can solve the problems of inaccurate conveying position of manual operation, high labor intensity of manual operation, low work efficiency, etc. , to achieve the effect of compact structure, high work efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

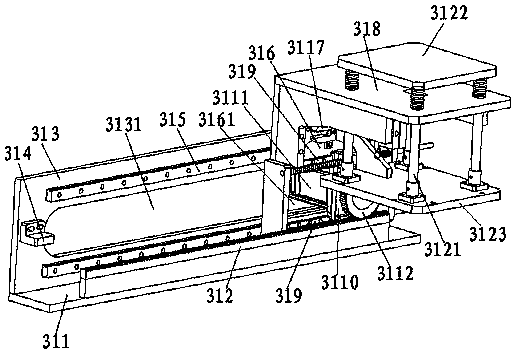

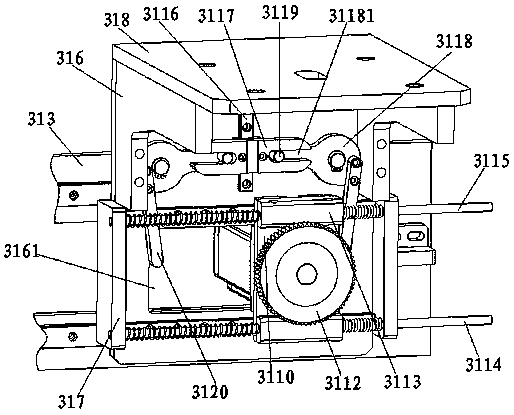

[0009] see figure 1 and figure 2 , the embodiment of the present invention includes:

[0010] A blanking and shifting device of a brake pump brake caliper loading machine, the blanking and shifting device of the brake pump brake caliper loading machine includes a shift mounting plate 311, the upper end surface of the shift mounting plate 311 passes through the The shift rack spacer is fixed with a blanking shift rack 312, and a shift vertical plate 313 is also fixed on the installation frame 1, the lower end surface of the shift vertical plate 313 is fixed with the upper end face of the shift mounting plate 311, and the shift Both ends of the front of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com