A kind of polystyrene microsphere with rough surface and its preparation method and application

A technology for polystyrene microspheres and rough surface, applied in the field of polystyrene microspheres and their preparation, can solve the problems of reducing the water resistance, solvent resistance and mechanical properties of polymer products, and increasing the difficulty of emulsifiers in processing, and achieves The surface is rough and uniform, the toxicity is low, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] In this embodiment, the mixed solution is diluted to about 0 times, and the method comprises the following steps:

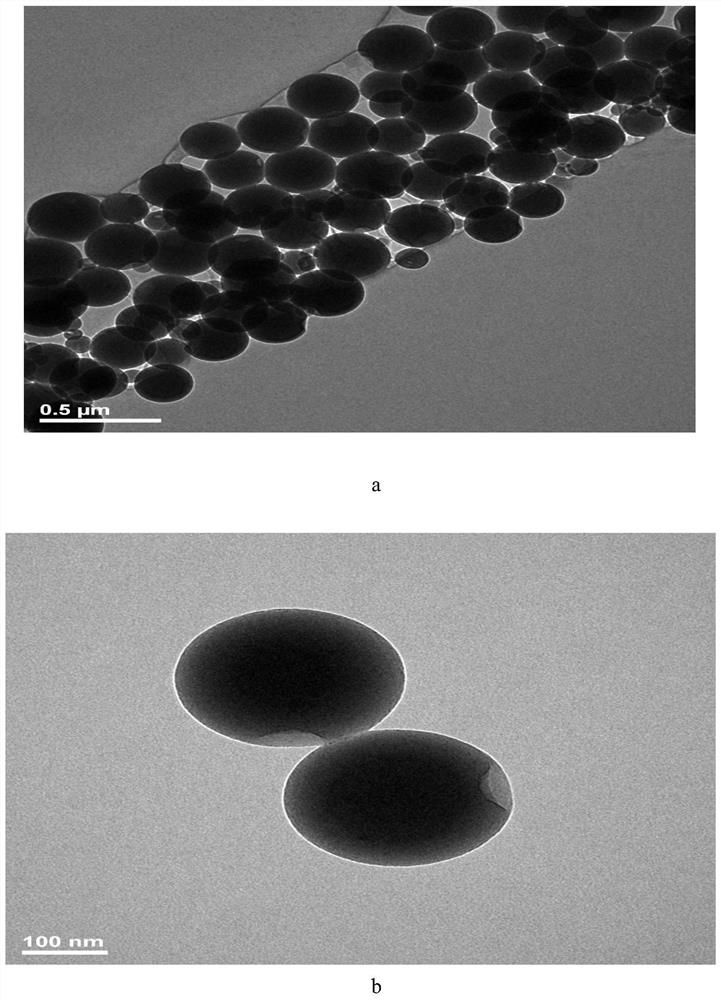

[0082] Measure 10ml of the mixed solution in a 250ml conical flask, use about 1.3ml of the mixed solution of ethanol and water and initiator K 2 S 2 o 8 0.0063g is made into a solution, and about 0.5ml of the mixture of ethanol and water is mixed with the reducing agent NaHSO 3 0.0044g was made into a solution, and the two solutions were quickly added to the above-mentioned Erlenmeyer flask, and placed at a constant temperature of 25°C for 24 hours. After adding ammonium chloride solid powder to the reactant and standing still for 24-48 hours, the target product surface rough polystyrene microspheres can be obtained through the steps of centrifugation, water washing and redispersion. The product was dissolved in ethanol and characterized by TEM. The polystyrene microspheres prepared in this embodiment are as follows: figure 1 As shown in (including a ...

Embodiment 2

[0084] In this embodiment, the mixed solution is diluted to about 5 times, and the method comprises the following steps:

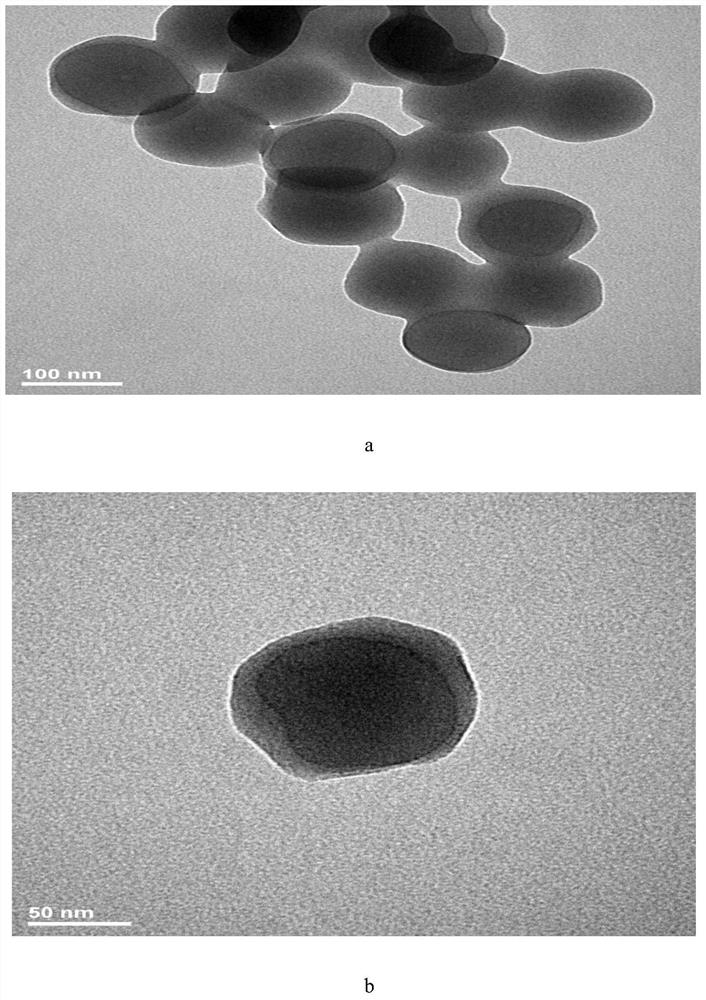

[0085] Measure 10ml of the mixed solution in a 250ml conical flask, use about 30ml of the mixed solution of ethanol and water and initiator K 2 S 2 o 8 0.03123g is made into a solution, with about 10ml of ethanol and water mixture and reducing agent NaHSO 3 0.0202 g was made into a solution, and the two solutions were quickly added to the above-mentioned Erlenmeyer flask, and placed at a constant temperature of 25°C for 24 hours. Add ammonium chloride solid powder to the reactant and let it stand for 24-48 hours, then centrifuge / wash with water to obtain the target product. The product was dissolved in ethanol and characterized by TEM. The polystyrene microspheres prepared in this embodiment are as follows: figure 2 As shown in (including a and b), it can be seen in the figure that the surface of each particle is rougher and more irregular than the p...

Embodiment 3

[0087] In this embodiment, the mixed solution is diluted to about 10 times, and the method comprises the following steps:

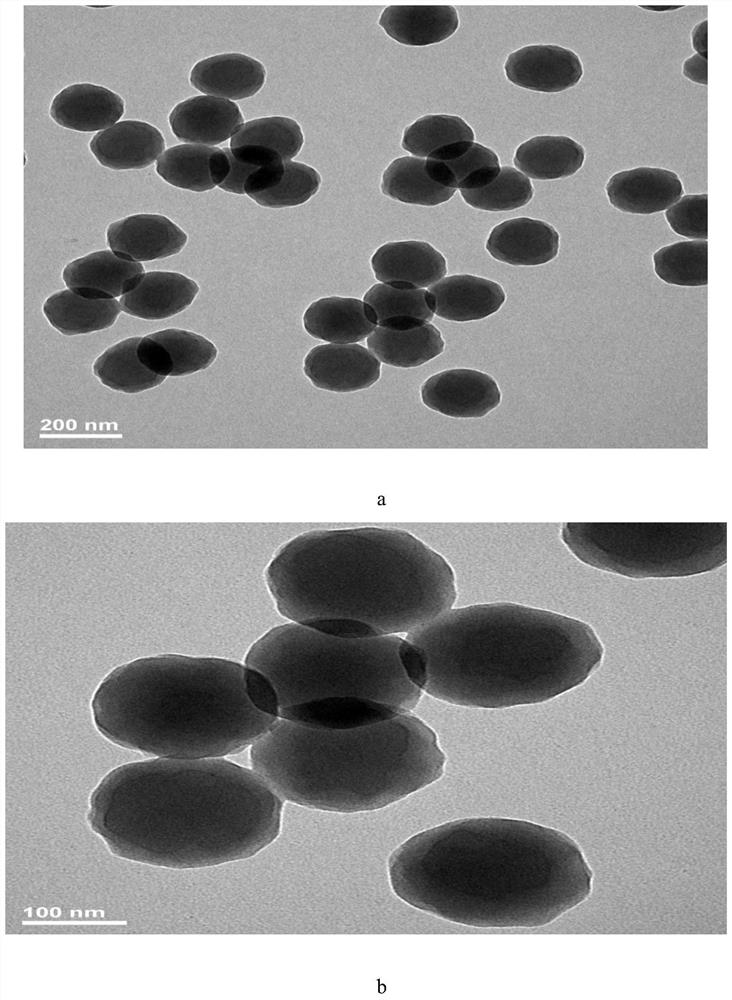

[0088] Measure 10ml of the mixed solution in a 250ml conical flask, use about 65ml of the mixed solution of ethanol and water and initiator K 2 S 2 o 8 0.0632g is made into a solution, with about 25ml of a mixture of ethanol and water and a reducing agent NaHSO 3 0.0410 g was made into a solution, and the two solutions were quickly added to the above-mentioned Erlenmeyer flask, and placed at a constant temperature of 25°C for 24 hours. Add ammonium chloride solid powder to the reactant and let it stand for 24-48 hours, then centrifuge / wash with water to obtain the target product. The product was dissolved in ethanol and characterized by TEM. The polystyrene microspheres prepared in this embodiment are as follows: image 3 As shown in (including a and b), it can be seen in the figure that the surface of each particle is rougher and more irregular than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com