Alcohol-ester coordinated whole wheat Pearson beer and preparation method thereof

A technology of beer and alcohol ester, applied in the field of beer, which can solve the problems of poor drinkability, uncoordinated alcohol and ester flavor, and high content of higher alcohols, achieve good coordination of bitterness/alcohol ester flavor, and solve the problem of high content of higher alcohols , good coordination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The embodiment of the present invention also provides a method for preparing the alcohol ester coordination type whole wheat Pilsner beer according to the above embodiment, comprising the following steps:

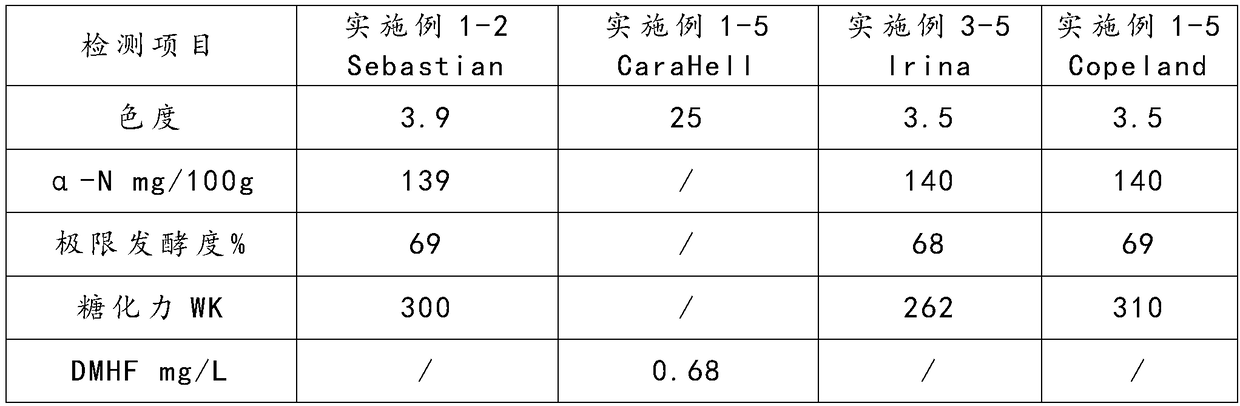

[0028] S1: Select Pilsner malt with light-colored caramel malt and water as the main raw materials, mix it with a material-water ratio of 1:3-1:4, and carry out two-stage mashing at 62-72°C. During the mashing process, the wort α- The N content is less than 180 mg / L.

[0029] In this step, when the malt is mixed with water, the requirements for the feeding time of the malt are different, that is, the dry crushed malt is fed at 50-55°C, and the wet crushed malt is fed at 62-65°C, so as to ensure the malt after crushing. Take advantage of. In addition, in this step, the saccharification process is optimized as a two-stage saccharification, and the traditional saccharification low-temperature protein resting process is cancelled, so that the α-N content of the wort can...

Embodiment 1

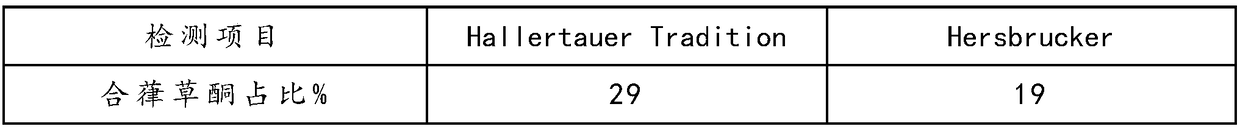

[0042] Barley malt (French Malt Sebastian Peel Malt 30%-49%, French Malt Quench Pearson Malt 25%-30%, Added Malt Copeland Pearson Malt 25%-30%, Light Color Caramel Malt CaraHell 1%-10% ), water as the main raw material, crushing→saccharification→filtering→boiling (hops Hallertauer Tradition 36%, Hersbrucker 64%)→gyroscope precipitation→cooling→oxygenation→adding the following yeast→fermentation→filtration→sterilization→that is, 10.5°P alcohol Ester-coordinated whole-wheat Pilsner beer.

Embodiment 2

[0044] Barley malt (French Malt Sebastian Peel Malt 30%-49%, French Malt Quench Pearson Malt 25%-30%, Added Malt Copeland Pearson Malt 25%-30%, Light Color Caramel Malt CaraHell 1%-10% ), water as the main raw material, through crushing→saccharification→filtering→boiling (hops Hallertauer Tradition 100%)→gyroscope sedimentation→cooling→oxygenation→adding the following yeast→fermentation→filtration→sterilization→the 10.5°P alcohol ester coordination type Type whole wheat pilsner beer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com