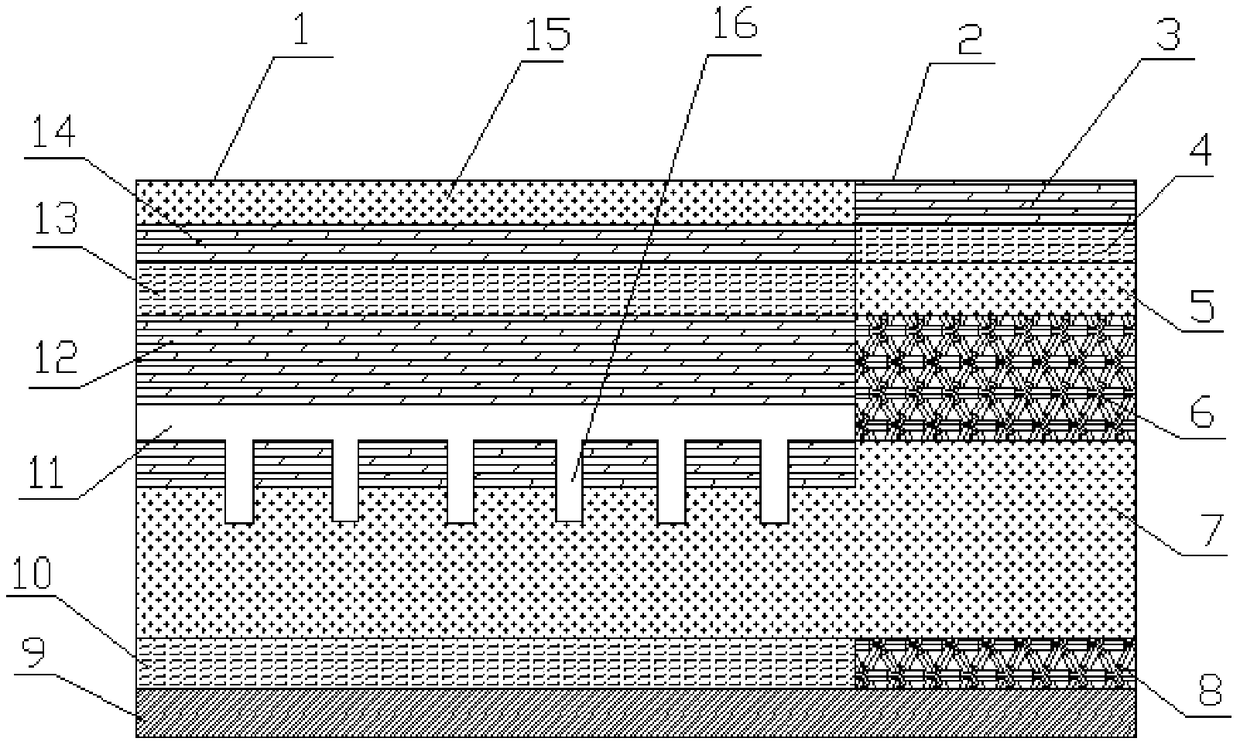

Sponge urban road adopting ventilated seepage-proof sand and construction method thereof

A sponge city and construction method technology, applied to roads, roads, side ditches/curbs, etc., can solve the problems of limited water storage function and ineffective connection of green belts, and achieve high sand making efficiency and reduced watering The effect of frequency and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of air-permeable anti-seepage sand, including raw sand, high-permeability epoxy resin, vinyl acetate polymer latex binder, by volume, raw sand is 88 parts, high-permeability epoxy resin is 5 parts, and the rest is vinyl acetate Based polymer latex binder, wherein the particle size of the original sand is 20 mesh.

[0039] A preparation method of air-permeable anti-seepage sand, comprising the steps of:

[0040] Step 1: Add the processed raw sand into the drying oven, heat the raw sand to 200°C, dry the raw sand, the moisture content of the raw sand is lower than 2‰, and store it in a dry place;

[0041] Step 2: Mix the dried raw sand, high-permeability epoxy resin and vinyl acetate polymer latex binder according to the volume ratio, add them to the mixer at 80r / min, stir and mix evenly, dry, and pulverize;

[0042] Step 3: Introduce the semi-finished product obtained in Step 2 into the heating drum, so that the high-permeability epoxy resin is bonded to the surf...

Embodiment 2

[0045] A kind of air-permeable anti-seepage sand, including raw sand, high-permeability epoxy resin, vinyl acetate polymer latex binder, by volume, raw sand is 92 parts, high-permeability epoxy resin is 3 parts, and the rest is vinyl acetate The base polymer latex binder, wherein the particle size of the original sand is 200 mesh.

[0046] A preparation method of air-permeable anti-seepage sand, comprising the steps of:

[0047] Step 1: Add the treated raw sand into the drying oven, heat the raw sand to 300°C, dry the raw sand, the moisture content of the raw sand is lower than 2‰, and store it in a dry place;

[0048] Step 2: Mix the dried raw sand, high-permeability epoxy resin and vinyl acetate polymer latex binder according to the volume ratio, add to the mixer at 120r / min, stir and mix evenly, dry, and pulverize;

[0049] Step 3: Introduce the semi-finished product obtained in Step 2 into the heating drum, so that the high-permeability epoxy resin is bonded to the surfac...

Embodiment 3

[0052] A kind of air-permeable anti-seepage sand, including raw sand, high-permeability epoxy resin, vinyl acetate polymer latex binder, by volume, the raw sand is 90 parts, the high-permeability epoxy resin is 4 parts, and the rest is vinyl acetate A polymer-based latex binder, in which the particle size of the original sand is 100 mesh.

[0053] A preparation method of air-permeable anti-seepage sand, comprising the steps of:

[0054] Step 1: Add the processed raw sand into the drying oven, heat the raw sand to 250°C, dry the raw sand, the moisture content of the raw sand is lower than 2‰, and store it in a dry place;

[0055] Step 2: Mix the dried raw sand, high-permeability epoxy resin and vinyl acetate polymer latex binder according to the volume ratio, add them to the mixer at 100r / min, stir and mix evenly, dry, and pulverize;

[0056] Step 3: Introduce the semi-finished product obtained in Step 2 into the heating drum, so that the high-permeability epoxy resin is bonde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com